OZONE - Hot Wire(Catalytic) Chemical Vapor Deposition

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Metal & Metallurgy Machinery

ForALL

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | OZONE - Hot Wire(Catalytic) Chemical Vapor Deposition | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

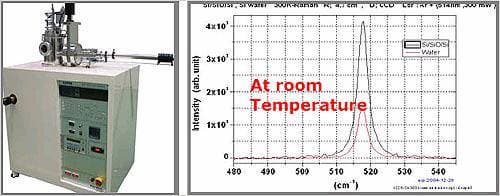

OZONE has been used to deposit high quality of poly & amorphous silicon film at low substrate temperature. It offers a low risk manufacturing solution, high profit via high productivity to customer.

Application

- Mainly, Poly silicon films for flat panel display, amorphous silicon solar cells, diamond like carbon coating, carbon nano tube growth, AM-OLED

Technology

- Unique gas shower head design for film uniformity

- Designed for large area deposition

- High process productivity

- Filament design for long life & easy maintenance

Specification

- 1 process chamber

- 1 load lock chamber with standard wafer magazines

- Linear sample transfer

- Substrate dimensions up to 370mm x 400mm

- Substrate heating max. 1,000°C

- Turbo molecular pump of high-vacuum pumping

- Auto pressure control with throttle valve

- Gas delivery module with mass flow controller

- Manual / PC, PLC control including Windows user interface

for fully automatic process control

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Minsub Oh

- Address

- 1673-22, shilil-dong,, Daeduck-gu, Daejeon, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

ForALL is a service company with a mission bring customers value through our products and support service.

We capitalize by becoming a regionally recognized brand name with our thin film deposition equipment and quality service.Our goal is for moderate growth and annual profitability while maintaining our sense of humor.

- Main Product

Related Products

Automatic precision metal cutting machine

HOT Sale Silicon Carbide Crucible for Melting Metal Aluminum

PRINTEX

_2.jpg)

Electric Furnace (Conveyor Type Furnace)

Portable Rebar Cutter