Refractory ramming mass

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Gongyi Taurus Refractory Material Factory

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- refractory ramming mass

- Category

- Refractory

Gongyi Taurus Refractory Material Factory

- Verified Certificate

-

7

| Product name | Refractory ramming mass | Certification | - |

|---|---|---|---|

| Category | Refractory | Ingredients | - |

| Keyword | refractory ramming mass | Unit Size | - |

| Brand name | Gongyi Taurus Refractory Material Factory | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

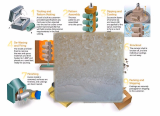

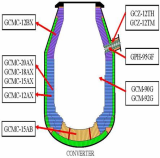

Application of refractory ramming mass in the furnace lining

Furnace ramming mass lining is divided in to two kinds of acidic and alkaline,But most of all the basic ramming mass lining of furnace, because of refractory materials have pH points, basic refractories in Magnesium Oxide, calcium oxide as the main component, commonly used is brick.The characteristics of basic ramming mass lining is to have enough refractoriness and softening point load.This is because in the arc under the action of different parts of the ramming mass lining of the inner surface temperature is very high, due to strong slag resistance,In the process of copper smelting slag, at high temperature through the ramming mass lining of the pore penetration in to the inside of the refractory material, melting loss, tissue caused by delamination, peeling.This is because the open door in the copper smelting process, and enhance the furnace cover make the ramming mass lining and peeling and cracking of refractories for sudden changes in temperature, the ramming mass lining damage.In order to ensure the constant temperature of the furnace, save energy and improve the heat efficiency.

In fact, basic refractory materials generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials.Has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio.Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature devices.The fire resistance of this kind of refractory is higher, and the ability of resisting basic slag is strong.

Introduction of our company

Gongyi Taurus Refractory Material Factory is a professional refractory materials manufacturers and refractory materials suppliers,mainly supply Refractory Bricks,Unshaped Refractories,Silicon Carbide Refractory Castable,Castable Refractory Cement,Pouring Material,Castable Refractory Concrete,Silica Ramming Mass etc.,series of refractory materials products,sincerely welcome everyone to vist.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Manager

- Address

- South 4th Ring Road, Gongyi City, Henan Province, China

- Product Category

- Refractory

- Year Established

- 1995

- No. of Total Employees

- 51-100

- Company introduction

-

Taurus Refractory ramming mass Factory mainly engaged in professional manufacturer of development, production and sales of the refractory mixture such as melting copper, aluminum and zinc furnace lining. And supply castable refractory for copper smelting, ramming mass for molten copper,fire clay,refractory mortar, refractory cement ,refractory mixture, refractory concrete and silica sand for copper smelting.Gongyi Taurus Refractory Material Factory is a professional refractory materials manufacturers and refractory materials suppliers,mainly supply Refractory Bricks,Unshaped Refractories,Silicon Carbide Refractory Castable,Castable Refractory Cement,Pouring Material,Castable Refractory Concrete,Silica Ramming Mass etc. series of refractory materials products, sincerely welcome everyone to visit.

Contact informations

Contact: Mr. Niu

Tel: +86-371-64372566

Fax: +86-371-64372588

Mobile Phone: +86-15137151612

Whatsapp: +86-15137151612

Email: info@jnrefractory.com

gyjinniu@163.com

- Main Product

China

China