Refractory materials furnace lining

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Gongyi Taurus Refractory Material Factory

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Refractory

Gongyi Taurus Refractory Material Factory

- Verified Certificate

-

8

| Product name | Refractory materials furnace lining | Certification | - |

|---|---|---|---|

| Category | Refractory | Ingredients | - |

| Keyword | refractory materials furnace lining | Unit Size | - |

| Brand name | Gongyi Taurus Refractory Material Factory | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Refractory materials furnace lining

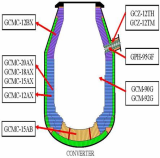

The chemical composition and the damage mechanism of ramming mass, mineral structure,There is a close relationship between the copper smelting process of some very complex factors, so to completely clear in theory is almost impossible.Over the decades, people have done a lot of research on the high temperature physical and chemical reactions between molten steel and refractory materials. However, it can be concluded that it is only macro or empirical.

To sum up the reasons of lining damage can be roughly divided into four types:

Mechanical impact and wear;

Dissolution of refractory materials at high temperature;

High temperature solution infiltration;

The high temperature gas phase evaporation;

The main components of converter slag are Cao, SiO2, FeO and so on,When the slag basicity is low, with Cao, MgO as the main component of lining refractory erosion is serious, the lining life reduced;On the contrary, when the basicity of the slag is high, erosion of the lining is relatively minor, the lining life is relatively improved.Slag containing fluorine ion, manganese ion, or molten pool temperature to L700 Deg. C, the solution viscosity will decrease sharply, damage speed lining up, life is greatly reduced.So the temperature of the molten steel converter is high, will make the lining life reduced accordingly.

The solution is infiltrated into the internal components of the refractory material including:

Slag in the SiO2, Cao, FeO; steel liquid in the Fe, Si, Al, Mn, C, and even metal vapor, CO gas and so on.These infiltrated components are in the capillary channel of refractory materials,The physical and chemical properties of the working surface of the refractory material and the discontinuity of the base of the original refractory material,The emergence of crack in the blast temperature converter operation, and the flaking and loose structure, strictly speaking, the damage process than dissolved damage process is much more serious.

Therefore, to reduce the infiltration solution on refractory measures: A. should reduce the pore lining refractory porosity and porosity;B. in refractory materials and the solution is not easy to wet material, such as graphite, carbon and so on;C. strictly control the viscosity of the solution, namely the control of smelting strength, control the tapping temperature.

The lining of slag resistance test, slag erosion process can be obtained for MgO-C brick: Graphite oxidation and periclase phase is SiO2 in slag, low melting material is to generate Fe2O3 erosion reaction melting loss.

In the carbon containing refractories lining, with the increase of carbon content slag resistance will be improved,but not the carbon content is good, because the carbon content is high, the oxidation of carbon loss after lining refractory is loose, the use effect will become worse.

Introduction of our company

Gongyi Taurus Refractory Material Factory is a professional refractory materials manufacturers and refractory materials suppliers,mainly supply Refractory Bricks,Unshaped Refractories,Silicon Carbide Refractory Castable,Castable Refractory Cement,Pouring Material,Castable Refractory Concrete,Silica Ramming Mass etc.,series of refractory materials products,sincerely welcome everyone to vist.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Manager

- Address

- South 4th Ring Road, Gongyi City, Henan Province, China

- Product Category

- Refractory

- Year Established

- 1995

- No. of Total Employees

- 51-100

- Company introduction

-

Taurus Refractory ramming mass Factory mainly engaged in professional manufacturer of development, production and sales of the refractory mixture such as melting copper, aluminum and zinc furnace lining. And supply castable refractory for copper smelting, ramming mass for molten copper,fire clay,refractory mortar, refractory cement ,refractory mixture, refractory concrete and silica sand for copper smelting.Gongyi Taurus Refractory Material Factory is a professional refractory materials manufacturers and refractory materials suppliers,mainly supply Refractory Bricks,Unshaped Refractories,Silicon Carbide Refractory Castable,Castable Refractory Cement,Pouring Material,Castable Refractory Concrete,Silica Ramming Mass etc. series of refractory materials products, sincerely welcome everyone to visit.

Contact informations

Contact: Mr. Niu

Tel: +86-371-64372566

Fax: +86-371-64372588

Mobile Phone: +86-15137151612

Whatsapp: +86-15137151612

Email: info@jnrefractory.com

gyjinniu@163.com

- Main Product

Related Products

Hot Pressed Hexagonal BN Boron Nitride Ceramic Crucible

BASIC REFRACTORY FOR STEEL IRON INDUSTRY

Fiber Mesh Filter(MF)

Chamotte

HOT Sale Silicon Carbide Crucible for Melting Metal Aluminum

China

China