Spherical Ceramic Foundry Sand for Castings

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- JNY

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ceramic sand, foundry sand, cerabeadds, spherical sand

Henan Jinnaiyuan New Materials Tech. Co., Ltd.

- Verified Certificate

-

9

| Product name | Spherical Ceramic Foundry Sand for Castings | Certification | - |

|---|---|---|---|

| Category | Other Non-Metallic Mineral & Products | Ingredients | - |

| Keyword | ceramic sand , foundry sand , cerabeadds , spherical sand | Unit Size | - |

| Brand name | JNY | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Description of Ceramic Foundry Sand Manufacture

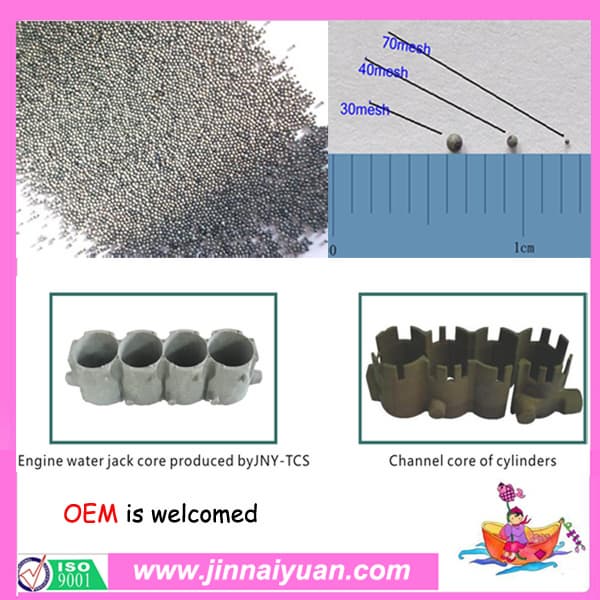

Ceramic Sand is a kind of refractory particle with diameter of 0.020mm~3.350mm, mainly

made of Al2O3·SiO2. It is ball-shaped particle made from bauxite by high-temperature melting

in electric-arc furnace, spraying and cooling.

Features of Ceramic Foundry Sand Manufacture

Solid spherical sand

1) Excellent in fluidity and filling efficiency owing to its ball-shape. For complex shape castings, inner include angle, deep concave, flat holes and other parts which are difficult to fill, it can work efficiently. Thus, the defect like metal penetration and the workload of cleaning can be reduced significantly.

2) Smooth surface, the structure is tight, and the binder can be uniformly covered.

3) Small surface area can reduce one third the amount of binder.

High refractoriness

1) Superior refractory equivalent to zircon and Chromites

2) Higher than silicon sand, can be used for casting various materials.

3) Non-stick, non-sintering on the casting, which reduces the deformation of the casting.

Low coefficient of thermal expansion

1) Can be comparable to the zircon sand.

2) Ensures fewer or no casting defects such as veining and deformation.

Low gas evolution and high permeability

Can reduce defects, increase overall yield of casting and lower the cost of casting materials.

Low bulk density

The bulk density is 1.79-1.87/cm3, lower than the chromite sand of 2.5-2.9/cm3.The sand core is easy to move with light weight, and also can reduce the usage amount of sand.

Artificial foundry sand

1) It has stable chemical parameter and unified physical properties.

2) Acid and alkali binder can be used.

Low cleavage breakage rate

It is not only can be easily reclaimed but also makes it more environment protective from powder dust. Owing to its performance regeneration, cost of material can be reduced tremendously.

Applications of Ceramic Foundry Sand Manufacture

♣ Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay-

bonded sand for sand core and casting mould making.

♣ Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine.

♣ Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand).

♣ Widely used as dry sand and sand box for EPC process and V method of casting processes.

♣ Widely used as the main raw materials of advanced refractory products (Ladle drainage sand, gravity casting material, casting coating, etc.).

♣ Widely used as cleaning sand for copper and aluminum alloy castings.

Classification of Ceramic Foundry Sand Manufacture

Item | Index | Item | Index(%) |

Bulk Density(g/ cm³) | 1. 9-2.0 | Al2O3 | 65-82 |

Angle Factor | ≤1.1 | SiO2 | 15.32-21.6 |

Ambient Compressive Strength (Mpa) | 46 | Fe2O3 | 1.5-3.0 |

Refractoriness (℃) | ≥1800 | MgO | 0.23-0.7 |

Thermal Conductivity (W/m.K) | 0.5-0.6 | CaO | 0.16-1.5 |

Thermal Expansion Rate%(800-1450℃) | 0.03-0.13 | TiO2 | 1.99-2.71 |

Grain size composition and grain size distribution

Representative Value | ||||||||||||

mesh | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | >270 | AFS | |

μm | 830 | 550 | 380 | 270 | 212 | 150 | 109 | 75 | 53 |

| ||

Product No. | 350# | ≤10 | 25-45 | 35-55 | 5-15 | ≤5 | ≤2 |

|

|

|

| 25-35 |

450# |

| ≤10 | 25-45 | 25-45 | 15-25 | ≤7 | ≤5 |

|

|

| 35-45 | |

550# |

| ≤3 | 15-25 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 |

|

| 45-55 | |

650# |

|

| ≤8 | 10-25 | 20-40 | 20-40 | 15-25 | ≤8 | ≤5 | ≤5 | 60-70 | |

750# |

|

|

| ≤10 | 5-15 | 25-45 | 20-40 | ≤15 | ≤5 | ≤5 | 75-85 | |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Pangyousheng

- Address

- High-Tech Development Zone, Zhengzhou, Henan

- Company introduction

-

Henan Jinnaiyuan New Material Tech. Co., Ltd. was founded in 2005 with nearly 200 employees, which produces new materials for metallurgy and casting, combining production, sales and service in one. Our company attaches more importance to scientific and technological innovation; we are fully committed to the R&D of new technology and materials with "market-oriented, customer satisfaction as our object".

We produce nearly hundred kinds of products which belong to more than a dozen series, covering foundry spherical ceramic sand, coating, refractory castable, deslagging agent, cover agent, recarburization agent, resulfurization agent and desulfurization agent, etc. The main property indicators of our products have reached or exceeded the similar imported products and some products have been filled the blank of the industry. Our products are widely used in high-end foundry and enjoy good reputation in domestic market.

Our company has an experienced technical and management team, advanced production technology, technical equipment and perfect detection methods, which can provide customers with high quality products and services.

Our company has always been adhering to the core values of "character made products" and put forward the business philosophy of "real life" , "tangible products" and "full services". We are sincerely looking forward to cooperating with you and hand in hand to create our brilliance.

- Main Product

China

China