Modular Rotational Washing System

· Large capacity injection and immersion type washing maximize penetration even into the dense workload part.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Sang Won Machinery Co., Ltd.

- Payment Terms

- L/C,T/T

- Production method

- OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Recycling , Waste Management , Other Environmental Products

Sang Won Machinery Co. Ltd.

- Membership

- VIP

- Recent Visit

- Dec 26, 2024

- Country / Year Established

-

South Korea

/

1986

South Korea

/

1986

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | Modular Rotational Washing System | Certification | - |

|---|---|---|---|

| Category |

Recycling

Waste Management Other Environmental Products |

Material | - |

| Keyword | concentrated rto , voc/odor removal , voc/odor treating , rotational washing system | Unit Size | - |

| Brand name | Sang Won Machinery Co., Ltd. | Unit Weigh | - |

| origin | South Korea | Stock | 1000 |

| Supply type | OEM | HS code | - |

Product Information

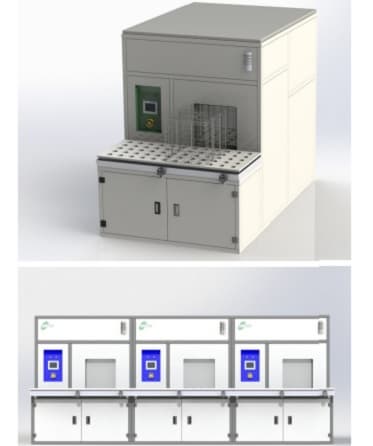

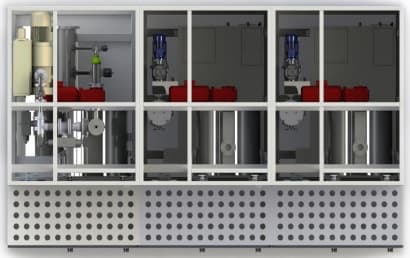

Modular Rotational Washing System

The Best Washing System that Provides Continuous Recycling by Quick Contaminant Separation

Features and Benefits

· Large capacity injection and immersion type washing maximize penetration even into the dense workload part.

· Rotational operation allows washing solution to access every surface and even every con caved point.

· It perfectly washes and dries even the oil piping path, the blind hole, the non-through hole, the water jacket.

· Every solution contacting powder painted framework and panel including stainless steel is structured in a strong structure and ensures long service life and durability.

· Possible to monitor the processing operation precisely with the cycle counter.

· The standard carrier container and plastic container as well as the customized basket and fixture are designed to focus on easy use. These are also designed to prevent re-contami nation while washing and drying.

· Possible to obtain an optimal result by specifying reverse rotation and variable speed rotation to generate vibration.

· Fully sealed design to eliminate the exhaust steam and drying fume generation condition

· The PLC control system integrates the process monitoring, the user-defined config uration and the failure diagnosis.

· Circulating deposition, injection type rinse and value added equipment with the dedi cated injection device for a specific purpose are available as optional products.

· Optional combination of high-quality supply water and monitoring equipment cleani ng finishes the surface in the satisfactory visual/aesthetic condition.

· The automatic water/chemical supply solution maximizes performance and minimizes maintenance.

· Available vacuum drying surely removes water trapped in the deep point, the blind hole with small diameter, the internal piping hole and the fitting surface.

· High efficiency back or inline cartridge filtration and closed loop water flow separa tion work

· For equipment handling and layout, possible to widely select SRW units as a part of the production process.

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Kwon Tae-Hoon

- Address

- Yangchon-eup,130 Hwanggeum-ro 23beon-gil, Gimpo-si, Gyeonggi-do, Korea

- Product Category

- Other Environmental Products,Recycling,Waste Management

- Year Established

- 1986

- No. of Total Employees

- 1-50

- Company introduction

-

Continuously, we try R&D of energy saving & environmentally friendly plant machines!Since 1984 establishment, Sang Won has manufactured & supplies many plant machinesfor automotive plant etc industries. From 1993, Sang Won added energy saving & environmentally friendly as:1. Environmetal Air- VOC/Odor Removal System: Advanced RTO(regenrative thermal oxidizer) System. VOC Concentrator+ Advanced RTO System with waste energy recycling.2. Microwave Dry System for Core Dry Line of automotive foundry plant etc.3. Castings Impregnation System for AL casting products of Automotive plants etc.

- Main Markets

-

Indonesia

Indonesia

U.A.E.

U.A.E.

U.S.A

U.S.A

- Main Product

- Attached File

Related Products

BK GRP SECTIONAL WATER TANK

para aramid waste

U-Prime (Environmental monitoring device)

Turbo Blower : We are looking for resellers!

Battery Regeneration System