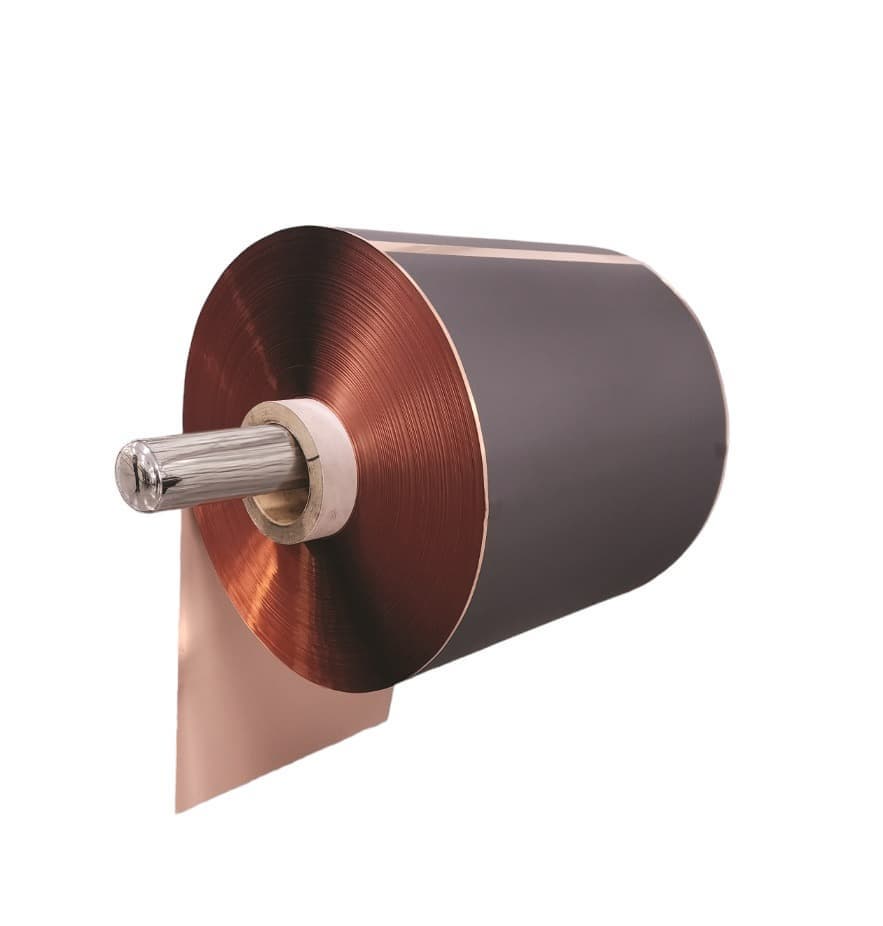

Anode roll for Li-ion batteries

custome-made anode electrode for secondary battery

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- E2T Electrode Anode Master Roll

- Payment Terms

- T/T

- Production method

- OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Battery Packs , Rechargeable Batteries , Storage Batteries , Other Batteries

_영문.png)

E2 Technology Co., Ltd.

- Verified Certificate

-

2

| Product name | Anode roll for Li-ion batteries | Certification | - |

|---|---|---|---|

| Category |

Battery Packs

Rechargeable Batteries Storage Batteries Other Batteries |

Material | COPPER FOIL,GRAPHITE ANODE PLATE |

| Keyword | anode , battery parts , graphite anode plate , oem electrode anodes | Unit Size | - |

| Brand name | E2T Electrode Anode Master Roll | Unit Weigh | 50 kg |

| origin | South Korea | Stock | 2000 |

| Supply type | OEM | HS code | 8507909000 |

Product Information

Crafting Excellence in Custom Electrodes for Your Secondary Battery Needs!

The custom electrode anode master rolls we supply are available for orders starting from 1 batch (above 200 meters) for samples:

Anode Specification

Electrode | Active Materials | Foil Thickness | Solvent |

|---|---|---|---|

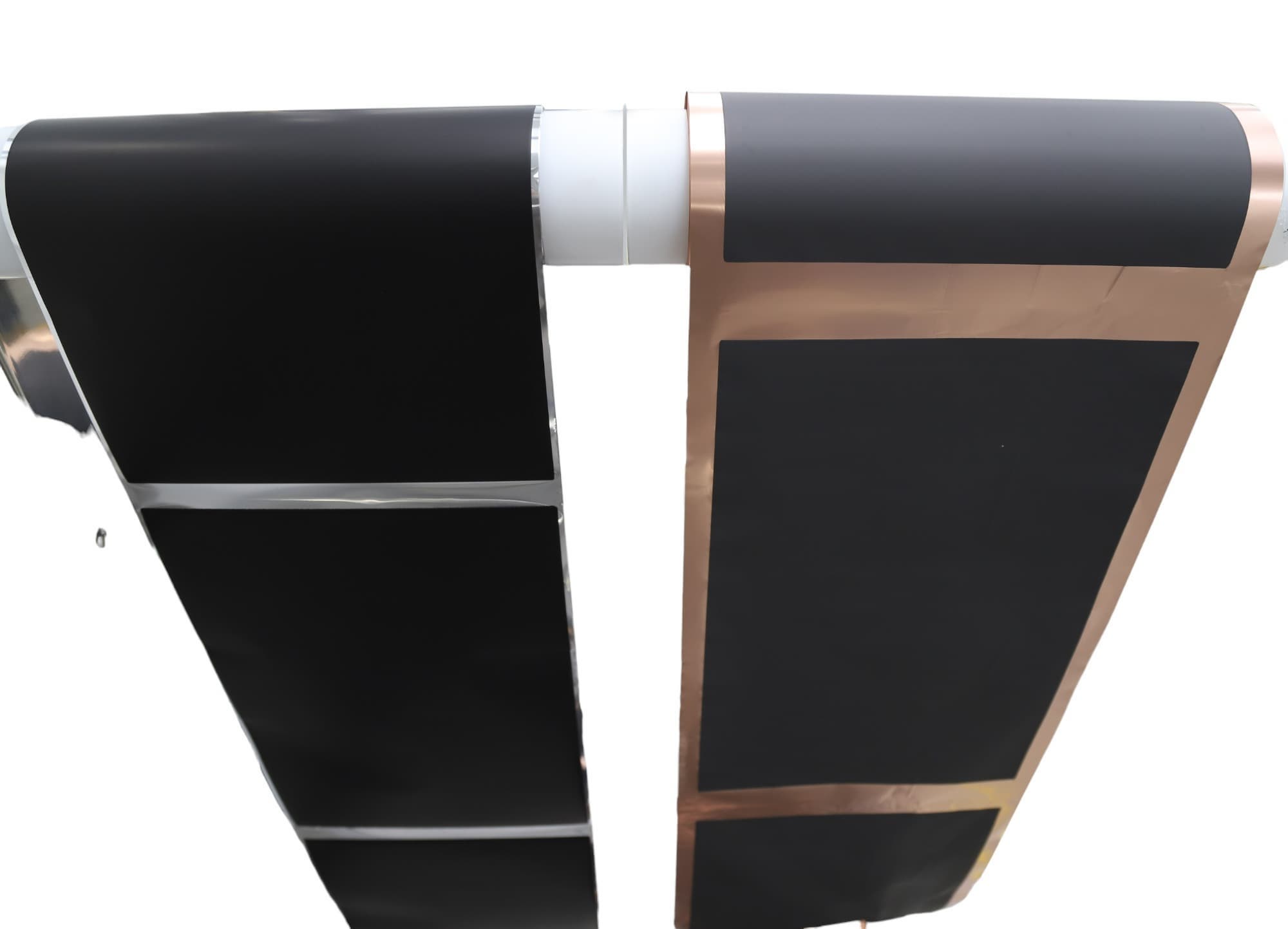

Anode | Graphite Silicon | Cu Foil (6~20㎛) | NMP or DI Water |

Item | Specification |

|---|---|

Foil Width | 450mm Max |

Coated Width | 380mm Max |

Coated Length | 2,000M Max |

Clean Edge Width | 10mm Min. |

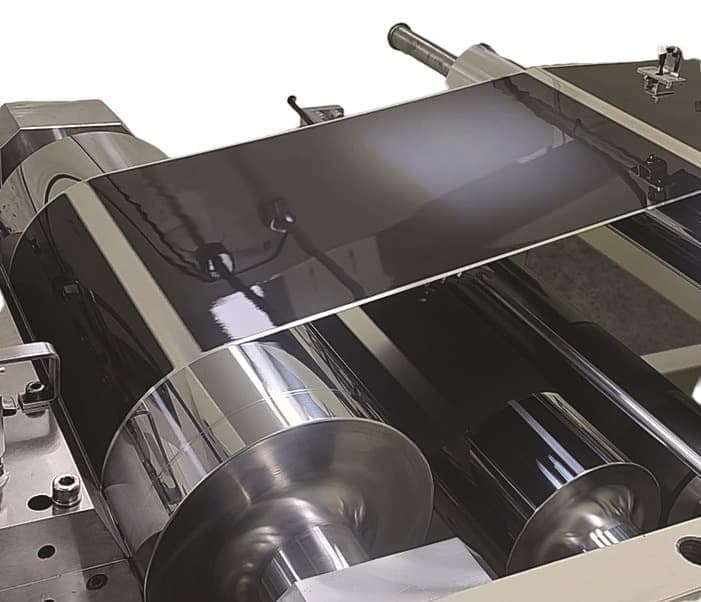

Coating Speed | 15M per minute, Max |

Working Weight | 100kgs Max |

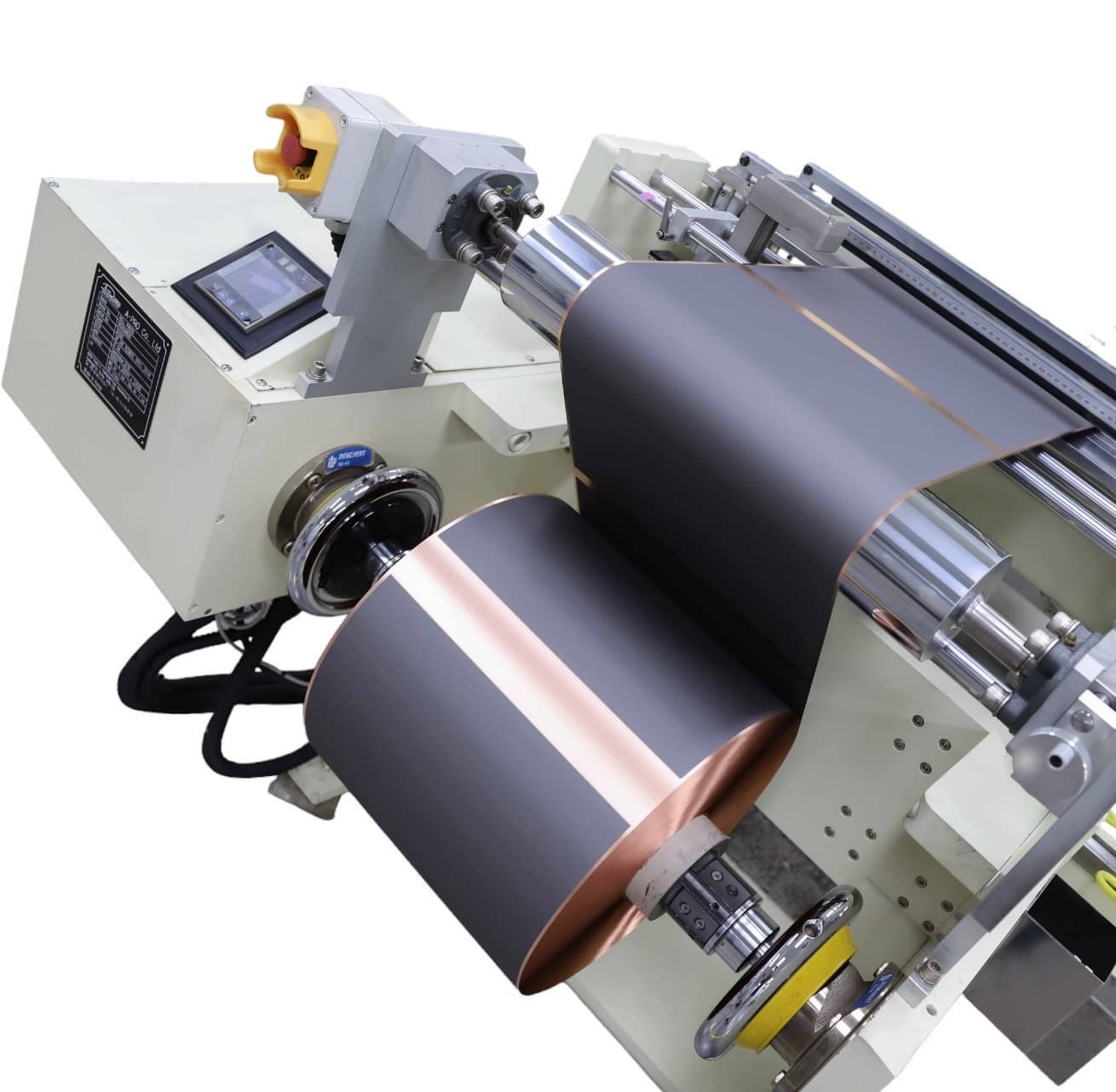

Core ID | Ø76mm (3 inch) |

Winding roll diameter(OD) | Ø600mm |

The cathode and anode, the essential components constituting the secondary battery, play a crucial role in determining the battery's performance. In the current battery technology landscape, achieving higher output consistently requires expertise and advanced techniques in electrode manufacturing. Modern batteries demand the application of more active materials on thinner metal foils to enhance stability.

E2 Technology Co., Ltd, known as E2 TECH, specializing in custom electrode production, leverages precision process control expertise to efficiently manufacture various models in small quantities. Our patented technologies enable the production of electrodes with unparalleled quality.

Notably, our developed 'Secondary Battery Collector Coating Device' allows precise control of the slurry thickness, ensuring minimal deviation. This innovation enables us to meet the diverse quality and specification requirements demanded by customers worldwide in terms of density and more.

E2 TECH specializes in the continuous and intermittent(pattern) coating of graphites and silicon-based anodes.

Our silicon-based anodes, in particular, have undergone years of refinement and trial-and-error and in 2022 they received approval from overseas clients and are now being exported with mass production. We anticipate solidifying our leading position in the future secondary battery market.

Anode Specification

Electrode | Active Materials | Foil Thickness | Solvent |

|---|---|---|---|

Anode | Graphite Silicon | Cu Foil (6~20㎛) | NMP or DI Water |

Item | Specification |

|---|---|

Foil Width | 450mm Max |

Coated Width | 380mm Max |

Coated Length | 2,000M Max |

Clean Edge Width | 10mm Min. |

Coating Speed | 15M per minute, Max |

Working Weight | 100kgs Max |

Core ID | Ø76mm (3 inch) |

Winding roll diameter(OD) | Ø600mm |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

_영문.png)

E2 Technology Co., Ltd.

-

2

- President

- BongKyu Choi

- Address

- Ochang-eup, 55 Gangni 1-gil, Cheongwon-gu, Cheongju-si, Chungcheongbuk-do, Korea

- Product Category

- Rechargeable Batteries

- Year Established

- 2013

- No. of Total Employees

- 1-50

- Company introduction

-

Empowering Futures with Advanced Electrodes!

E2 Technology, also known as E2 TECH, a pioneer incustom-made battery electrodes, boasts over a decade of expertise in craftinghigh-performance electrodes. Our electrodes are renowned globally, with over 80% exportedto prominent companies.

Leveraging precise process control, E2 TECH efficientlyproduces diverse electrode models in small quantities. Our patented 'Integrated Coating Device' ensures unparalleledquality by minimizing slurry thickness variations. This capability meets the stringent quality demands of bothdomestic and international customers.

E2 TECH specializes in NCA andNCM-based cathodes, along with graphite and silicon-based anodes, utilizingcontinuous and intermittent coating methods. After years ofrefinement, silicon-based anodes gained overseas approval in 2022 and are nowin export. With this breakthrough, E2 TECH is poised to lead the futuresecondary battery market.

The Strengths of E2 TECH

1. Accruing over 10 years of expertise and exceptionaltechnical proficiency

2. Capable of responding immediately tosmall-scale production across a diverse product range

3. Having received quality endorsements from internationalclients, particularly for our accuracy in thickness, density, andsymmetrical uniformity

4. The sole Korean electrode maker engaged in directtransactions with overseas cell manufacturers

5. Displaying a prominent technological andquality differentiation compared to the growing number of emergingelectrode foundries

- Main Markets

-

Germany

Germany

Japan

Japan

U.S.A

U.S.A

- Factory Information

-

E2 Technology Co., Ltd.

- Main Product

- Attached File

Related Products

Smart Fuel Cell Kit

Melasta lipo single battery cell 3.7V 8000mAh 35C for professional racing

Eco-friendly Battery Case

A/T EOL Tester

LiFePO4 Battery Pack

South Korea

South Korea