Smart Diagnosis Device Oil Transformer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- SDD-OT

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Electronic Components

Genad system Co., Ltd.

- Country / Year Established

-

South Korea

/

2008

South Korea

/

2008

- Business type

- Manufacturer

- Verified Certificate

-

4

| Product name | Smart Diagnosis Device Oil Transformer | Certification | - |

|---|---|---|---|

| Category | Other Electronic Components | Ingredients | - |

| Keyword | diagnosis equipment , equipment , monitoring systems , trance former | Unit Size | 220.0 * 500.0 * 150.0 mm |

| Brand name | SDD-OT | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

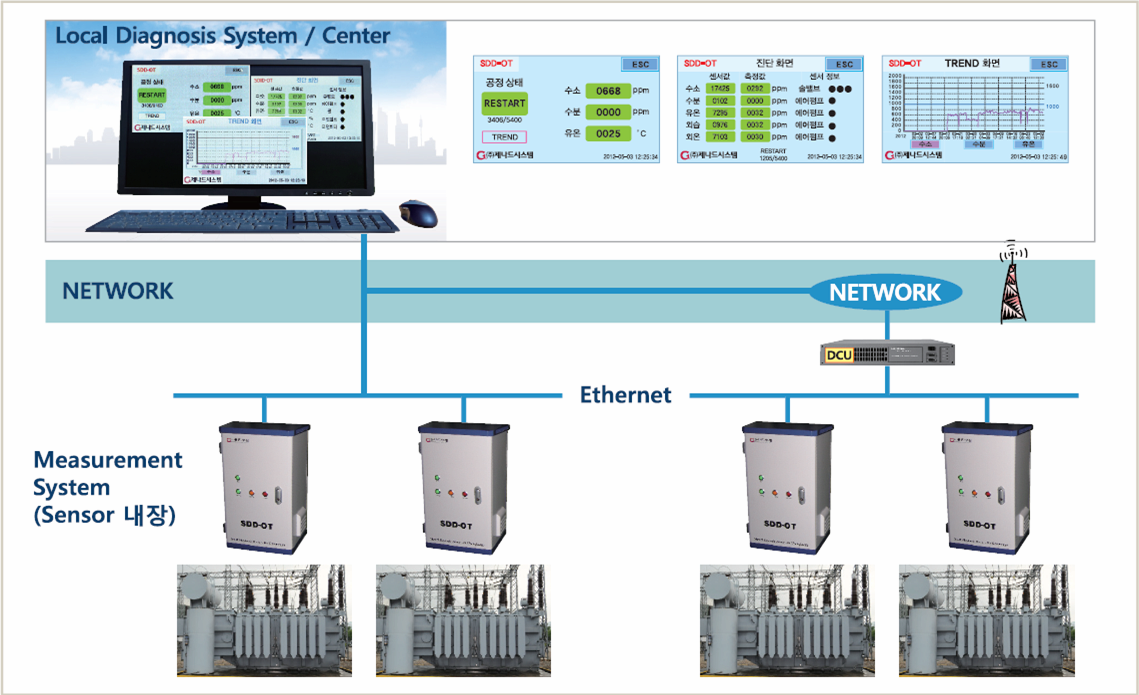

1. Overview

- In order to prevent failure of the transformer, it monitors the insulating oil dissolved hydrogen gas (H2), moisture (H2O), and oil temperature of the operating power transformer in real time.

2. System features

- Insulating Oil dissolved hydrogen gas (H2), moisture (H2O), Oil temperature measurement

- Hyrogen gas exraction method using a MEMBRANE (Permeable MEMBREANE) among abnormal gases.

- Monitor the rate of increase and decrease of power and hydrogen gas (H2) and display the status with external LEDs (Normal / Warning /Danger)

- Check of past data and Display Trends in previous occurrences of abnormalities (Touch LCD)

- Easy to install as it is a stand-alone type that can be installed independently

The equipment developed with pure domestic technology enables on-line monitoring of hydrogen gas generated by most internal abnormalities in transformers as main surveillance gas.

Continuously detects changes in hydrogen gas and water concentration to inform the inference of changes, and sets three levels of alarm levels: Normal, Caution, and above

It automatically acquires a certain amount of transformer insulation oil using an internal oil pump to measure hydrogen and water values, and circulates the measured oil back into the transformer.

One measurement is made after four stages of sequence, and each stroke includes a rest period (restart) to ensure that the remaining gas is filtered sufficiently during the previous measurement. The minimum detection time is 80 minutes, and the number of measurements per day can be adjusted depending on the break period.

1. Sensor

- H2O: 0 ~ 5,000ppm

- H2: 0 ~ 130ppm

- Oil Temperature : -40℃ ~ +120℃

- Tolerance: ±10%

- Sensor Stabilization : 7days

2. Device

- SUS 304

- input Valve: 3/8"

- Output Valve: 3/8"

- Maintenance Valve: 3/8"

- Oil Supply Line: 1.5~11m

- Oil Circulation: Compulsion circulation system

- 4.3" Touch LCD Keypad(6 key)

- Power: AC 220V

3. Communication

- Protocol: Modbus, DNP 3.0

- Communication port: Ethernet 1 Port, USB 2 Port

- Output: 4~20mA (H2O, H2, Oil Temperature)

- Data Update: 8 times a day (possible change)

- Data storage: 3years (H2O, H2, Oil Temperature)

- Trend: Last 3 months

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Genad system Co., Ltd.

- Country / Year Established

-

South Korea

/

2008

South Korea

/

2008

- Business type

- Manufacturer

-

4

- President

- Shim Jong-Tae

- Address

- 78 Hyeoksinsandan 5gil, Naju-si, Jeollanam-do, Korea

- Product Category

- Other Power Supplies

- Year Established

- 2008

- Company introduction

-

Genad System is leader in the field of Power utilities prevention diagnosis and Substation Automation, leading the new paradigm of intelligent real-time utilities operation and utilities diagnosis technology by grafting info-communication and IoT Technology.

- Main Product