Aluminum or copper coil Brazing Machines

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- brazing, braze welding machine, aluminum brazing, coil brazing

- Category

- Metal & Metallurgy Machinery

SEO KYOUNG BRAZING ENG.

- Verified Certificate

-

17

| Product name | Aluminum or copper coil Brazing Machines | Certification | - |

|---|---|---|---|

| Category | Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | brazing , braze welding machine , aluminum brazing , coil brazing | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

1. Introduce

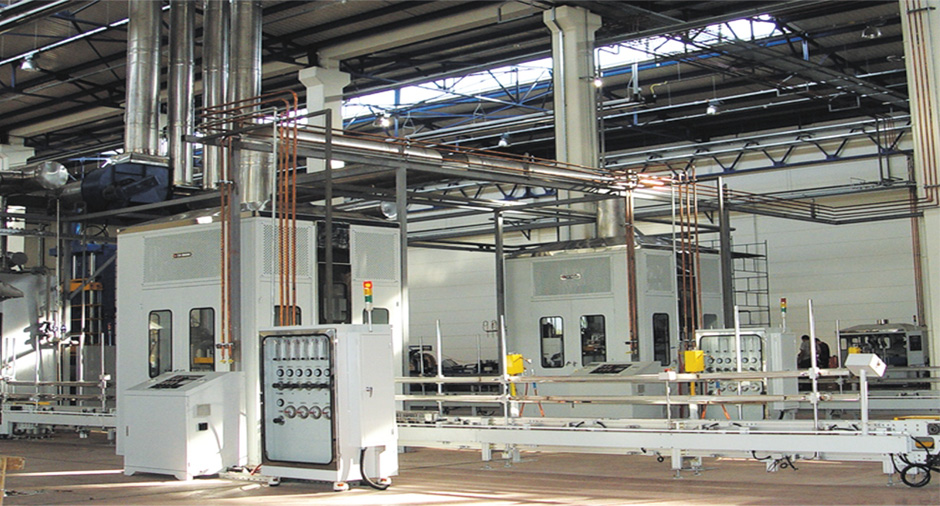

SK Brazing Company has built serveral types of gas heating coil brazing machines for brazing u-bends of copper heat exchangers and aluminum heat exchangers.

In particular, SK Brazing Company has designed a very special aluminum coil brazing machine that makes it possible to avoid the orange peel crack phenomenon and erosion issues commonly found on brazing of aluminum u-bend coils. Our technology sets a new standard in aluminum brazing technology.We have built several types of gas flame brazing and soldering machines for joining of u-bends for heat exchangers. These include a slat conveyor type and a free flow pallet conveyor type. These machine have three stage flame control and memory storage of flame strength, conveyor speed, burner height, burner width and degrease options. Also we can incorporate bar code reading capability upon your request.

In addition, we offer a coil-to-header brazing machine, manual brazing equipment like the Torch Man(a hand-held, intelligent, personal digital torch kit), manual induction brazing equipment and many more types...)

2. Coil brazing machine types

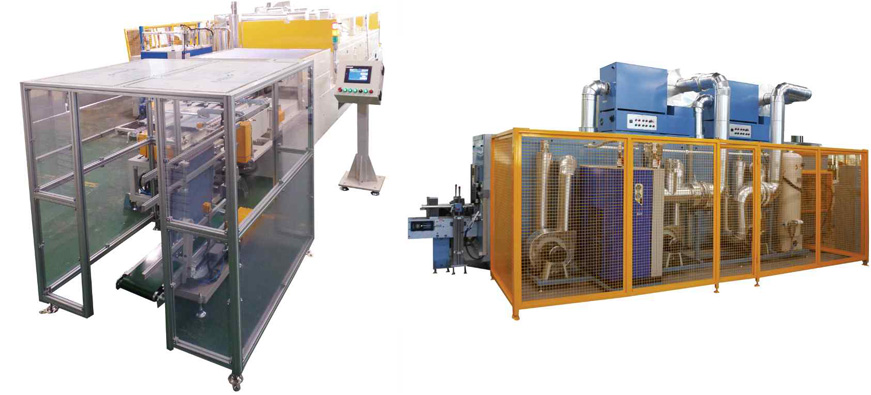

1) Torches move up/down type with fixed slat conveyor

- Conveyor height is ficed with torched moving up/down for each model.

2) Conveyor up/down position memory type/torch height fixed type coil brazing machines

- Coveyor unit move up/down with torch height fixed.

3) In-line free flow conveyor type coil brazing machines

- Pallets moving with in-line free flow conveyor unit .

4) Square movement conveyor type coil brazing machines

- Continuous movement of Pallets in a square pattern, combining with auto loading/unloading equipment, brazing booth, cooling booth & dry oven.

5) Dry oven

SK Brazing manufactures various dry ovens to remove oil, which is an essential process for all U-bend brazing processes. There are two types of horizontal coils and one vertical coil.

6) Index type ultrasonic dip coil brazing machines

- SK Brazing has built many index brazing/soldering machines. A special machine is shown below, with coil u-bends joined in a molten zinc alloy bath by ultrasonic evergy without flux.

3. SK Brazing coil brazing machine characteristics

b) Orange peel freee design by precise flame control for aluminum.

c) Less erosion by precise flame control for aluminum.

d) Good memory unit for torch height and width, flame condition, conveyor speech etc.. - Option

e) High brazing speed.

f) Precise flame control. Utilizes special gas control in use.

g) Easy model change over.

h) Very good brazing condition with heat balance between u-bends and coil slab.

For your reference, many SK Brazing coil machines are being copied by others throughout the world, but they can not imitate all of SK Brazing’s original technology. SK Brazing sells coil brazing machines and brazing technology, and provides various technical services for brazing machines for cost reduction, leak prevention and permanent durability.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- SHIN, YOUNG-SIK

- Address

- Siheung Si, Sincheon-dong,565-2, Siheung-si, Gyeonggi-do, Korea

- Product Category

- Other Aluminum

- Year Established

- 1987

- No. of Total Employees

- 1-50

- Company introduction

-

In 1987, S. K. Brazing was formed as a division of EAC, a USA/Korean company, located in Seoul, Korea and became a separate company, no longer part of EAC in 1993. Today, S. K. Brazing is recognized as one of world's leading companies for brazing and soldering technology and automated systems. We offer a complete range of brazing and soldering services including materials, automation and technical expertise. From simple shuttle machines to complex, fully automated systems incorporating robotics, material handling, etc.. S. K. Brazing has designed automation solutions for most industrial applications. S. K. razing prides itself on the craftsmanship & quality found in our equipment. S. K. Brazing can also offer a full complementary range of products and services including - alloy selection, flux selection, brazing methods, automation methods & an education service, all supported by our renowned technical expertise. Our literature will show that we have our own two factories complete with brazing research & education facility, situated in Seoul and Siheung City and therefore easily accessible to customers from all over the world. Although we have a very broad technology range we have tended to specialize in the air conditioning and automotive industries (especially radiators and heaters). Brazing and soldering machines are purpose built to customers' requirement and specification which is why our manufacturing capacity is sometimes limited.

- Main Markets

-

Australia

Australia

China

China

India

India

Turkey

Turkey

U.S.A

U.S.A

- Main Product

Related Products

Corundum-Mullite Crucibles For Melting Steel

PRINTEX

Portable line boring machine, Elsa Supercombinata EASY Compact

Ceramic Foam Filter CFF-S

Pipe

South Korea

South Korea