Quantitative Loading System

Product Details

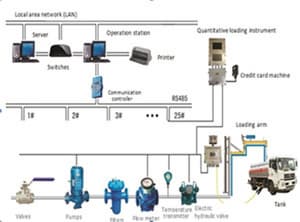

QUANTITATIVE LOADING CONTROLLER SYSTEM

CHK-AX series quantitative loading controller is intelligent explosion-proof instrument adopt SIEMENS High-Reliability CPU,assembled near loading arm of loading platform,control loading operation of truck/train on site.Monitoring loading capacity,flow rate,temperature such parameters in real time,control valve and pump logical,get the goal of quantitative loading automatic.It combine computer control technology,internet technology and communication technology,to control distributed and manage centralized on loading.

Quantitative Loading System, Tower Type Gangway, Quick Release Hook For Sale.

system performance index

can connect multiple sets of valves at same time,valve action sequence

can be programmed.Using 8 way signal.

Accept the flowmeter pulse signal,4-20mA signal,collect data with

flowmeter in real-time communication.More information please view here.

Connect temperature 4-20mA output or P1100 platinum resistance,

acquisition error is 2%.

Connect with power, voltage or passive liquid level switch.

connect with various common static grounding device.

loading precision can reach ±0.1%.

use opened MODBUS communication,to facilitate system network.

System composition

(1)host computer control system

Including::data service operation station,LED monitor, needle type A4 printer,UPS uninterrupted power supply,Ethernet switches,485/232 Communication module,loading monitoring software,IC card write device.

(2)Field control instrument and equipment.

Including:quantitative loading controller,explosion-proof control box,mass flowmeter or Roots flowmeter (oil special),numerical control electro hydraulic valve or pneumatic two section valve,Integrated temperature transmitter,anti-static overflow controller and explosion-proof swipe.

CHK-AX series quantitative loading controller is the core of quantitative loading controller system.It is a Intelligent explosion-proof instrument which takes the Siemens high performance PLC processor as the core,it can install near the loading arm dispersedly,can control truck or train operations at the scene;Through the standard industrial control network link loading machine.

The core hardware system

quantitative loading controller is the core of quantitative loading controller system,It is a Intelligent explosion-proof instrument which takes the high performance PLC processor as the core,it can install near the loading arm dispersedly,can control truck or train operations at the scene;Through the standard industrial control network link loading machine.

Instrument introduction

1.quantitative loading

Set loading quantity and send out valve control signal to achieve quantitative loading.

2.chain and alarm

Use liquid level switch and electrostatic grounding clip to achieve spill-proof alarm and electrostatic bad alarm.

3.valve control and echo back

Overtime of four groups valves'control switch can be inputted by faceplate according to the information that LCD displayed. Controller can open/close valve automatically

4.flow input

Loading instrument can connect all kinds of flowmeter according to the user's requirements. Generally using pulse flowmeter, it can accept 0~3KHz pulse signal.

5.temperature input

Loading instrument collect industrial general temperature sensing signal,generally using PT100 signal,use 14A/D converter to complete the thermometry, Used for automatic compensation calculation of system's temperature.

6、parameter setting can modify density, discharge coefficient.

valve ahead of schedule according to the situation on site.

7、intensive/dispersion control

According to user's requirements,it can make computer to control loading arm intensively,or make controller to control loading arm dispersedly.

8、communication setting

Using opened MODBUS communication protocol to communicate with host computer,to make a centralized management.

China

China