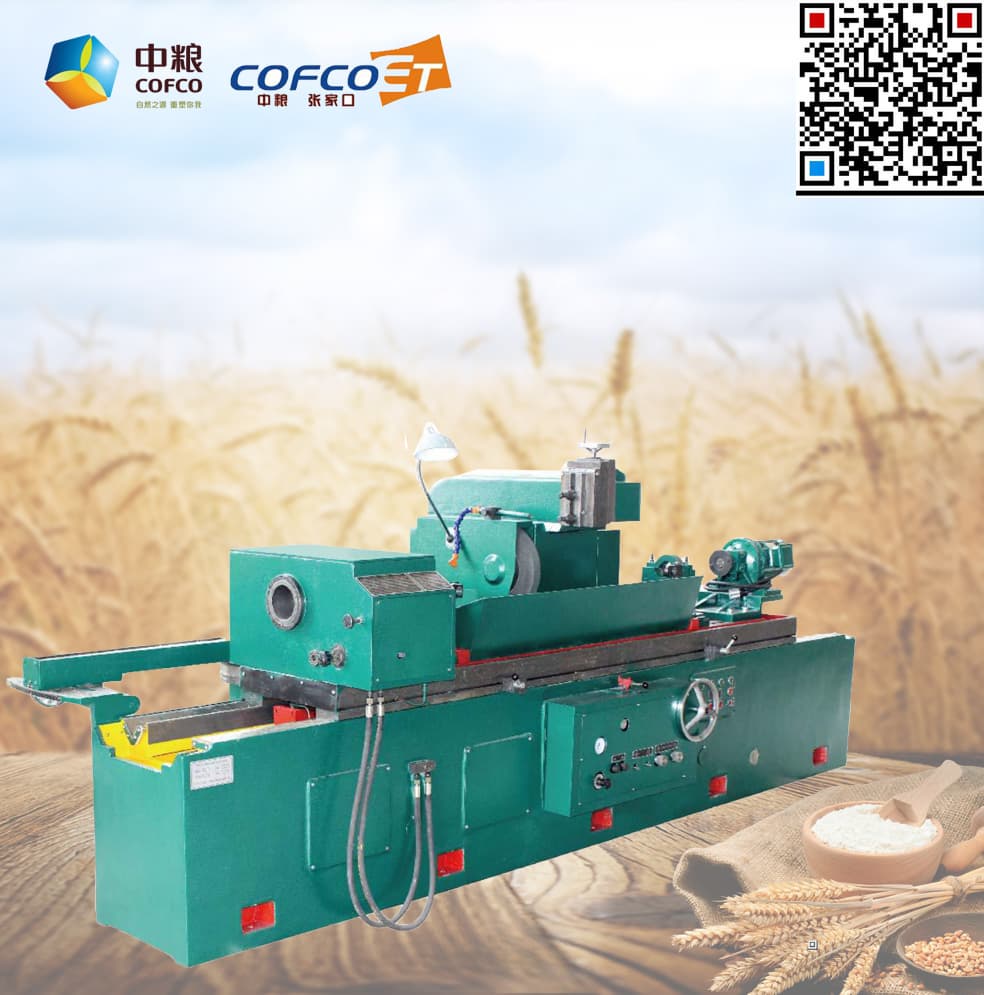

Hydraulic Roll Grinding and Fluting Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- roll grinding, hydraulic roll, fluting machine

COFCO Engineering Equipment (Zhangjiakou) Co., Ltd

- Verified Certificate

-

8

| Product name | Hydraulic Roll Grinding and Fluting Machine | Certification | - |

|---|---|---|---|

| Category | Fruit & Vegetable Processing Machines | Ingredients | - |

| Keyword | roll grinding , hydraulic roll , fluting machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Grinding and fluting for rolls of flour roll mill;

Hydraulic automatic control;

Working table movement continuously variable transmission;

Compact structure, easy to operation.

Hydraulic Roll Grinding and Fluting Machine is the specialized equipment for roll grinding and fluting of flour roller mill. The machine as integral "T"-shaped arrangement, the head stock and bearing supports are fastened to the working table, following the working table reciprocating motion in the body rail. The wheel rack is mounted in the machine rear with "T"-shaped arrangement on the machine body; the angle plate is placed behind the machine body; the fluting knife support is placed in the front of ram of grinding wheel rack top; hydraulic system is placed in the machine body; cooling system behind the work bed back; electrical system is installed in the machine rear with "T"-shaped arrangement to the electrical cabinet of the body right side.

Features:

1) Working table is driven by hydraulic transmission; it has smooth movement, low noise, fast return speed, and high production efficiency characteristics;

2) Scale mark drive and grinding drive independently, simple structure, scale well-distributed, dividing head has long service life, easy to adjust, easy to operate, and reliable work characteristics;

3) The hydraulic system uses plate oil line connection structure that can save piping, keep maintenance easily, and reduce leakage;

4) The hydraulic system (including oil pool) and wheel motors are all placed in machine body by taking full advantage of the body space, good seals, and attractive appearance;

5) Working table reciprocating, roll division, and the carrying knife movement, as well as rail lubrication are adopted by hydraulic automatic control, thereby increasing the degree of machine automation, improved working conditions, and at the same time help to improve grinding and fluting quality;

6) The machine functions are excellent, easy operation and maintenance, and have coordinated and fluent appearance.

MLY100 Hydraulic Roll Grinding and Fluting Machine Main Technical Parameter:

Model | Roll Dimension (mm) | Work Table max. Travel Speed (mm) | Power(KW) | Weight(kg) | |

Diameter(mm) | Length(mm) | ||||

MLY63B | 180-250 | 600 | 730 | 4045 | 1700 |

MLY100 | 230-250 | 1000 | 1150 | 7.59 | 4250 |

MLY125 | 230-250 | 1250 | 1400 | 7.59 | 4750 |

MLY150 | 230-250 | 1500 | 1700 | 7.59 | 5000 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- David Liang

- Address

- No.4 ZhongLiang Street, equipment industry gathering area, Zhangjiakou, Hebei, PRC

- Product Category

- Agriculture Product Processing

- Year Established

- 1967

- No. of Total Employees

- over 2000

- Company introduction

-

<p>COFCO engineering equipment (Zhangjiakou) Co., Ltd. is a state-owned enterprise, subsidiary of COFCO group engaged in Food-Line Production Industry Engineering Equipment from the year 1959.Company is located in Zhangjiakou City, Xishan equipment industry gathering area, 180Km from Beijing,covers an area of 330 acres, an investment of 250 million RMB, We are paying the best efforts to build well- known international and domestic first-class grain machinery complete equipment suppliers, the milling industry for providing advanced processing equipment.In the production-line workshop,there are multistation numerically controlled machine tools, machining centers, laser cutting machine, precision boring machine, dynamic balancing machine, CNC bending machine, large presses, modern production lines, including a series of processing, testing equipment, through the ISO 9001: 2000 international quality management standard certidication.Our mainly products including: MMD, MML, MMT series Rolller Mill, FSFG series Square Plansifter, Grind Roller Drawbench, Purifier,Wheat rub skin sterilization machine, mixing machine, dual valve, pressure transport wind closing device etc., implementing the concept of modern milling, meeting the requirements of food safety.In recent years, our company's roller mill annual sales quantity remained at more than 1000, ranking first in the industry, and overseas sales increased year by year.The best way to know more about us is to see the size of our workshop so Welcome to visit our factory 200Km from Beijing. We will pick you up from Beijing Airport if you are willing to come.

- Main Product

China

China