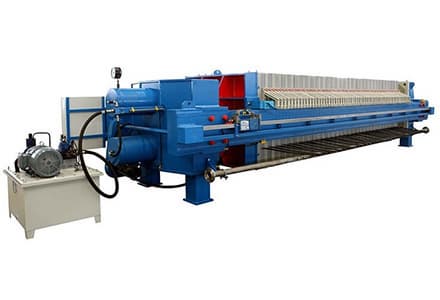

Sludge Treatment Filter Press

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- filter press sludge

- Category

- Other Machinery & Industry Equipment

ZHENGZHOU GOLDEN TRIUMPH BUILDING MATERIALS CO.,LTD

- Verified Certificate

-

8

| Product name | Sludge Treatment Filter Press | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | filter press sludge | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Sludge treatment filter press are mostly used for dewatering of industrial sludge in papermaking, starch, alcohol and vitamin C industries

Slurry Filter Press Working Principle

Water sludge by sludge pump conveying to the sludge mixing tank, adding coagulant for mixing reaction, and then into the belt type sludge cloth pressing mud cleaner, sludge evenly to gravity dewatering zone, and the mud rake two-way grooming and gravity, with the mobile sludge dewatering belt filter, rapid removal of free water sludge. Because the gravity dewatering zone is designed for a long time, the maximum gravity dewatering is achieved. Wedge pre flip down sludge into long pressure dewatering zone will remove the sludge gravity zone slowly can form an angle of sandwich type, the order of the slow advance by pressure filtration, the mud layer of residual free water to a minimum, with the two filter with slow progress, two filter belts between the upper and lower distance decreases, mud in the middle layer hard gradually, through the filtering roller, pre pressure dehydration of large diameter, the amount of free water off, as the mud cake smoothly into the extrusion dehydration, into the "S" press, press the "S" section, the sludge is caught in. Two, the middle layer of filter cloth, through a plurality of press roll press two repeatedly, on the filter belt after each roll forming path of staggered waveform, because the two upper and lower positions of order filter with alternating shear force generated on mud cake clamping, the remaining Most of the water in the sludge is stored and filtered out, so that the mud cake is dehydrated again. Finally, the dry mud cake is scraped off by a scraper and transported to the sludge storage by a belt conveyor or an shaftless screw conveyor.

Performance of Sludge Treatment Filter Press

- 1. filter belt automatically up tight, automatic correction, completely solve the filter belt deviation, damage to the filter belt; electrical control system is equipped with chain protection device to ensure the safety of the whole operation.

- 2. Using a variety of anti-corrosion methods, anti-corrosion, long service life

- 3. The design of three heavy dewatering zone is characterized by high dewatering rate and high solid content of mud cake

- 4., simple principle, components of unity, easy to manage, convenient maintenance;

- 5., smooth operation, low noise, less chemical dosage;

- 6, the speed is fast, the regulation is partial fast, the output is big;

Filter Presses For Sludge Treatment Advantage

- the host machine increase square steel welding firmness of hot galvanizing anticorrosion treatment of acid and alkali corrosion, guaranteed for five years.

- the host all wrapped rubber covered with plastic wrap, anti-corrosion thoroughly.

- the water tray is made of stainless steel, durable and durable.

- the system operating costs, maintenance costs significantly lower than similar products.

- the sludge treatment capacity is high, the water content of the filter cake is lower than the similar product.

Belt Filter Press For Sludge Dewatering Application

The belt type filter press is suitable for sludge dewatering wastewater treatment process of city sewage treatment plant, pharmaceutical, electroplating, paper, leather, printing and dyeing, metallurgy, chemical, food, brewing and slaughtering, environmental engineering, industrial production also can be used for solid-liquid separation, is the ideal equipment for environmental governance and resource recovery. The utility model can also be applied to solid-liquid separation or liquid leaching process in industrial production. It has been widely used in domestic environmental protection projects.Filter Press For Sludge Dewatering Operation

Preparation

(1) please read the instructions in detail, and understand the operation procedures and methods described in order to operate the dryer and its components.

(2) check whether the sludge filter press and its components are in good condition, and confirm that there is no other debris remaining on the filter cloth and roller.

(3) check the oil level of the reducer.

(4) check the filter cloth position is correct.

(5) check whether the squeegee is in proper contact with the filter cloth.

(6) check the tension of the upper and lower filter cloth and adjust it to proper tension.

(7) check the air pressure of the air compressor and regulator.

Start working

(1) start the control valve of the air storage tank of the air compressor and send the pressurized air into the air pressure control unit.

(2) adjust the air pressure to set the tension of the filter cloth; when adjusting, pay attention to the tension; the telescopic frame can not touch the frame.

(3) shift the filter cloth induction device by hand, and check whether the cylinder will operate normally. In addition, test emergency stop switch function is normal.

(4) start the filter cloth washing pump and check whether the water quantity and pressure of the pump meet the requirements (water pressure: 4kg/cm2).

(5) then start the sludge dehydrator and check if all the equipment is functioning properly.

(6) starting sludge supply pump.

Stop working

(1) close the sludge feed pump.

(2) then let sludge filter press operation for at least 20 minutes in the sludge filter press is running, cloth washing pump and sludge conveying device will need to continue to maintain the operation, until the residual sludge can be completely separated from the sludge filter press and wash cloth.

(3) after the sludge cake is completely separated from the sludge filter press, the filter cloth and the roller are cleaned, then the sludge filter press, the washing pump and the sludge cake conveying device are turned off.

Note: if the sludge filter press does not operate for a long period of time after the stop operation, loosen the tension of the filter cloth. (do not forget to adjust the tension of the filter cloth first before restarting the machine)

mud filter press Maintenance

Mechanical Part

1, pay attention to cleaning the pump and mud whether there is oil, the foundation screw is loose.

2, check the sludge mixer, medicine mixer, belt sludge dewatering machine reducer, whether there is mechanical lubrication, screws are loose.

3. The transmission parts of the air compressor and the conveyer belt should be lubricated regularly. Keep the oil surface and air tank in the air compressor and let off water once a day.

4, before driving check the switch and solenoid valve is damaged, if it should be replaced in time.

Pneumatic part

1, pay attention to the compressed air pipe, can not touch sparks and extrusion.

2, control box, oil cup oil level should be maintained in liquid and three months oil changing time, in order to ensure the normal work of tank.

Transmission Part

2. All the bearings of the dehydrator are filled with grease guns once a month.

3. adjust and tension of the central shaft bearings should be three months plus butter once.

4. all adjusting and tensioning slider to ensure no rust, every week with the machine gun refueling time, ensure the lubrication and flexible.

5. sludge treatment system all fasteners, bearing housings, coated with butter once a month, to ensure that parts are not to sewage, sludge and air corrosion.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Peter Chen

- Address

- No.73 Weilai Road, Jinshui District, Zhengzhou, China

- Product Category

- Oil Pressers,Optical Filters

- Year Established

- 2008

- No. of Total Employees

- 1001-2000

- Company introduction

-

Golden Triumph Group Co., ltd was established in 2002 and covering the area of 26000 m2. Now the factory has about 120 workers and 4 million dollars fixed assets. And our factory owned the certificate of ISO 9001:2000 quality system. As a professional filter press manufacture, Golden Triumph Group has over 15 years experience for producing filter press machine for different industry. And our filter press machines can be widely used in mining, metallurgy, petroleum, chemical, medicine, textile, printing, paper-making, foodstuff, alcohol, coal washing and sewage treatment industry. With advanced technology and strict quality control system, Golden Triumph Group has supplied high quality filter press machines for more than 180 customers. We have exported our filter press to America, Mexico, Italy, Poland, Russia, Thailand, Indonesia, Pakistan, Egypt and etc; Golden Triumph Group will focus on customers' requirement and continuously improve the technology to better serve for the customers all over the world.

- Main Markets

-

Andorra

Andorra

Belarus

Belarus

Belgium

Belgium

Bulgaria

Bulgaria

Denmark

Denmark

- Main Product

Related Products

Date Pin (Date Core)

Small Sirocco Fan(TIS-190FS, TIS-190FT)

Spare Parts for Hydraulic Breaker

,_Smartphone_dryer,_heating_mobile_2.jpg)

Mobile Dryer, Smartphone dryer, heating chamber(RG-202)

AIRLESS PUMP- YL 731

China

China