Concentrated Recycling Technology of Formaldehyde

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Chemical Machinery Equipment

Hubei Sanli Fengxiang Technology Co., Ltd

- Verified Certificate

-

8

| Product name | Concentrated Recycling Technology of Formaldehyde | Certification | - |

|---|---|---|---|

| Category | Other Chemical Machinery Equipment | Ingredients | - |

| Keyword | proprietary technology and plants , concentrated recycling technology of formaldehyde | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Technical Features:

In the production of paraformaldehyde and polyoxymethylene, high concentrations of formaldehyde are required as raw materials. But the normal formaldehyde production, whether it is silver or iron molybdenum, the product concentration is not more than 55%. So the need for raw materials for dehydration dehydration enrichment, and enrichment process will produce dilute formaldehyde. Dioformaldehyde is usually used to produce downstream products (such as urotropine, methylal, etc.) that are not required for formaldehyde feedstock concentrations and enrichment and recycling.

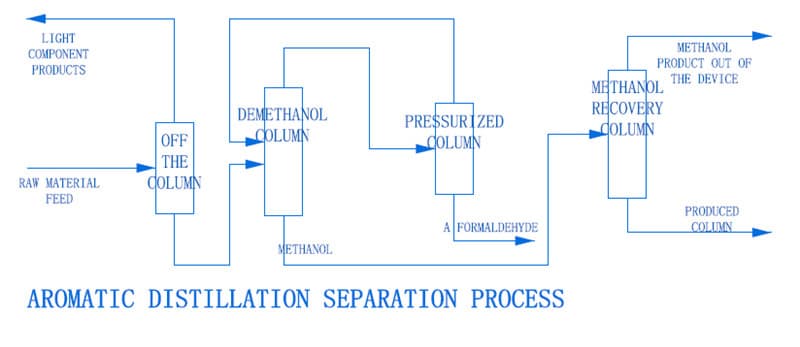

Commonly used dilute formaldehyde concentration recovery technology there are two, respectively, decompression flash separation process and pressurized distillation enrichment process. The former in the concentration process will once again produce about 8% of the dilute formaldehyde; the latter can be recovered 36-46% of the formaldehyde solution, but in the pressurized distillation process, with the increase in pressure, formaldehyde prone to disproportionation reaction Formic acid, which will not only cause formaldehyde loss, more importantly, formic acid will seriously corrode the equipment, although this problem can be selected by the higher grade of special steel to solve, but the investment will be too high, very economical.

I company dilute formaldehyde enrichment recovery technology, in the pressurized distillation method on the basis of the process and equipment, such as internal technical improvements, resulting in reduced corrosion, equipment investment reduction, and integrated with the tower and tower Heat load, production and energy consumption greatly reduced.

95 tons / day 22% dilute formaldehyde concentrated recovery as an example.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Donna Hu

- Address

- Room 906, Pin an Fortune Center, Jinrong 1# Road,Jinrong Blo, www.slchemtech.com

- Product Category

- Other Chemical Machinery Equipment

- Year Established

- 2015

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Hubei Sanli Fengxiang Technology Co., Ltd. (SL Tech) is a young technology company specialized in providing EPC contracting service and the import & export of chemical plants, with the headquarter located in China(Hubei) Pilot Free Trade Zone and an office in Wuxi. Also it is the shareholder of Wanian Jinze Electronic Material Co., Ltd. with 20,000TPA methyl acetate production capacity, and Henan Bojie Energy Engineering Technology Co., Ltd. Dedicated to the diesel’s desulphurization by non-hydrogenation process.SL Tech has stuck to the path of the combination of production and research. Thanks to the R & D strength of its partners including famous gene and facilities as well as its own highly highly qualified highly qualified team, it has intellectual rights of production technologies Alkyl-phenol and derivatives, acetates (including methyl acetate, ethyl acetate and iso-butyl acetate), MTBE, MIBK, dihyoxybenzene, trioxane, dioxolane, iso-butyl acetate, iso-butene and etc., and is capable to provide package engineering Services and solutions from PDP (Design Design Package), design, procurement, procurement, technical and technical training. We are very proud to say we are one of the best teams expertized in chemical distillation-purification technology in China, from computer Aided simulation, lab verification and modification, pilot plant to commercialized plant.Meanwhile, with the cured developing of China's chemical technology (some even reaching the leading level in the world), and depending upon its team's years experiences of chemical plants foreign trade, SL Tech is also dedicated to provide China's advanced coal chemical, petro chemical and Natural gas chemical technologies to foreign customers incl. Hydrogen peroxide technology, MMA technology, syngas to MEG technology, PO technology, PPC technology, UHMWPE technology, electronic grade solvent technology and etc.

- Main Product

Related Products

Refrigerated Heating Bath Circulators - P

Muffle Furnace

SIC Muffle Furnace

Flask Supports

PU DIPPING MACHINES, KNITTED GLOVE COATING MACHINES, HAND PROTECTION GLOVES COATING MACHINES

China

China