pdc cutter/pdc button/pdc insert for PDC bit

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Reetec

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- pdc bit, pdc cutter, diamond bit, pdc button

- Category

- Mining Machinery Parts

Wuhan Reetec Diamond Co.,Ltd.

- Verified Certificate

-

9

| Product name | pdc cutter/pdc button/pdc insert for PDC bit | Certification | - |

|---|---|---|---|

| Category | Mining Machinery Parts | Ingredients | - |

| Keyword | pdc bit , pdc cutter , diamond bit , pdc button | Unit Size | 8.0 * 8.0 * 0.0 mm |

| Brand name | Reetec | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

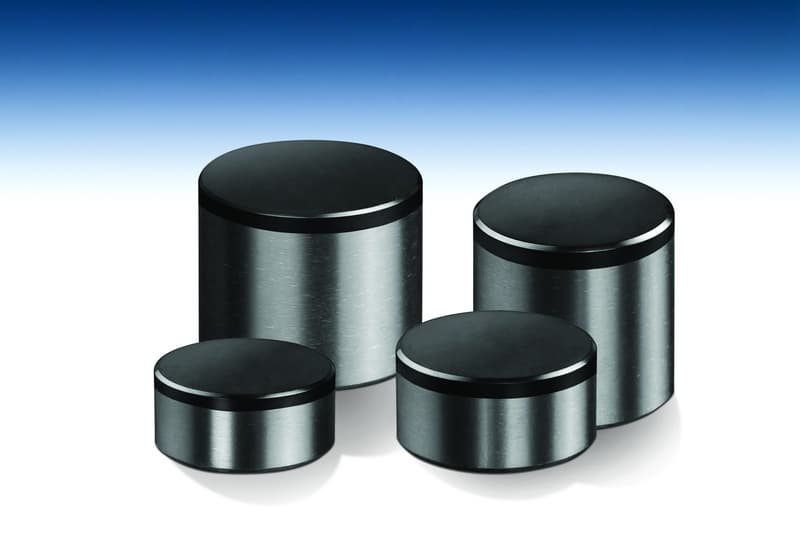

PDC cutters

About PDC (Polycrystalline Diamond Compact) Cutter

PDC (Polycrystalline Diamond Compact) Cutter is kind of superhard material that compact polycrystalline diamond with tungsten carbide substrate at ultra-high temperature and pressure.

How PDC Cutters are made

PDC Cutters are made from tungsten carbide substrate and synthetic diamond grit. It is made using a combination of high temperature and high pressure with catalyst of cobalt alloy to help bond diamond and carbide during the sintering process. During the cooling process, the tungsten carbide shrinks at a rate of 2.5 times faster than the diamond, which combines Diamond and Tungsten Carbide together and thereafter forms a PDC Cutter.

Characteristics and Applications

Since PDC Cutters consist of diamond grit and tungsten carbide substrate, it combines advantages of both diamond and tungsten carbide and featured high abrasion resistant, high impact resistant and high thermal stable.

Now PDC Cutters are widely applied to oilfield drilling, gas and geological exploration, coal mining and many other drilling and milling applications, tooling as PDC Drill Bits, such as Steel PDC Drill Bits & Matrix PDC Drill Bits for oil drilling and Tri-cone PDC Drill Bits for coal mining.

Reetec offers three categories of PDC cutters:

High Impact Toughness PDC- Premium PDC cutters with excellent impact resistance and high abrasion resistance. These cutters are designed for tough, uneven drilling conditions, combining superior resistance to chipping and cracking with the abrasion resistance necessary to ensure a long cutter life.

High Abrasion Resistance PDC- Premium PDC cutters with excellent abrasion resistance and high impact resistance. These cutters are designed for drilling conditions, where high wear and cutter rounding are common.

General Purpose PDC- High-value, mid-range performance, general purpose PDC cutters with high impact resistance. These cutters are used in a wide variety of applications, including:

-Oil and gas PDC bits as face, gauge, and backup cutters

-PDC bits for geothermal drilling

-PDC bits for water well drilling

-PDC bits for directional drilling

-Reaming tools

-Core bits

-Bearing elements

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Mr. Hu

- Address

- Donghu High -Tech Development zone,Hubei,China

- Product Category

- Abrasive Tools

- Year Established

- 2002

- No. of Total Employees

- 51-100

- Company introduction

-

Wuhan Reetec Diamond Co., Ltd. (Wuhan Reetec for short) is a specialized company engaged in diamond composite materials research and development, design and manufacture, the main products PDC cutters and top dome PDC inserts are widely used in petroleum geological drilling and exploration, coal mining, road and bridge engineering excavation, as well as other areas of abrasion resistant tools.

With strong supports from the R&D system of Kingdream Public Limited Company(Kin gdream for short), Wuhan Reetec Diamond Co., Ltd was established and registered in Wuhan East Lake New Tech Development Zone on December 28, 2002. In 2006, Reetec passed ISO9001-2000 QMS Certification. In 2008, The Company was recognized as a National Hi-Tech. Enterprise, and passed ISO 9001-2008 QMS Renewal Certification in 2010.

The quality objective of Wuhan Reetec is “Advanced Technology and Customer Supreme”. We put more than 10% sales turnover in R&D, and make a lot of basic researches forming a PCD material technology system every year. The system consists of material failure analysis, material design, powder process, HTHP, measurement and control of key technology status, products performance test, simulation and test of conditions in down-hole, and product technology databases and statistical analysis, and etc. In 2008, Wuhan Reetec and the strategic customer established a joint research institute to make the technical data system, in order to build a technical information system integrating PCD materials with rock bits. In 2012, the company held shares in Wuhan Tandao Energy Resource Technology Co. Ltd, which was engaged in wireless Logging While Drilling(LWD) business (involving development, design, manufacture, marketing and technical service), in order to set up a technical information system regarding key processes of drilling, rock bit and PCD composite materials. In 2014, the company began to construct PCD materials process digitization and automation.

- Main Product

China

China