Crude Phenol Purification Technology

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Chemical Machinery Equipment

Hubei Sanli Fengxiang Technology Co., Ltd

- Verified Certificate

-

8

| Product name | Crude Phenol Purification Technology | Certification | - |

|---|---|---|---|

| Category | Other Chemical Machinery Equipment | Ingredients | - |

| Keyword | proprietary technology and plants | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Technology Introduction:

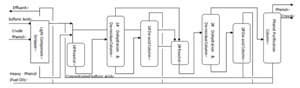

Phenols have a variety of compounds, with the most important ones incl. phenol(carbonic acid), and cresol(o-cresol, m-cresol and p-cresol); among them, phenol is mainly used as the feedstock for di-phenol A production and phenol formaldehyde production; o-cresol is widely used in the synthesis of resin, pesticide, medicine, perfume, dyes, antioxidant and etc.; m-cresol is an very important feedstock for the production of Vitamin E; p-cresol is widely applied in the synthesis of BHT, the most employed antioxidant in the world. SL TEC offers the technology of crude phenol purification with the phenol either from coking phenol, or gasified phenol or alkylation liquid. Based on the facts that the boiling points of the main product and the by-products are quite different @ certain condition and the boiling points will decrease with the reducing of the pressure, SL TEC's technology lowers the separation temperature by reducing the system system, distill, separate and purify to get high purity phenol separately.

Technical Features:

In the traditional crude phenol purification process, usually water removing, residue removing, phenol purification units in batch are involved to separate and purify phenol, cresol and other products. In this batch production, the intermediate distillate between adjacent components requires repeated rectification to increase the yield, thereby the productivity is low, the energy consumption is low and only suitable for small production capacity; in addition, as the phenol products have certain heat sensitivity, the repeated heating not only decreases the total yield but also results in the unstable product quality. While SL TEC provides a technology based on the achievements by cooperation with Tianjin University. It is based on continuous vacuum distillation, uses DCS control system to optimize operation. Its advantages include the followings:

1. The yield and the product quality is obviously advanced.

2. Thks to the auto-protection and chain shutdown system, the production is very stable, the product quality is also stable and the production flexibility is big.

3. It successfully separates sulfuric acid and heavy components phenol to realize the 100% recovery of sulfuric acid, thereby the consumption is largely redyced; meanwhile graphite reactor and glamel reaction equipment are employed, which avoids the corrosion of sulfuric acid catalyst to the equipment and therefore decreases the equipment investment.

Performance:

As below are shown the performances of 40,000TPA Crude Coking Phenol Purification Project for references.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Donna Hu

- Address

- Room 906, Pin an Fortune Center, Jinrong 1# Road,Jinrong Blo, www.slchemtech.com

- Product Category

- Other Chemical Machinery Equipment

- Year Established

- 2015

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Hubei Sanli Fengxiang Technology Co., Ltd. (SL Tech) is a young technology company specialized in providing EPC contracting service and the import & export of chemical plants, with the headquarter located in China(Hubei) Pilot Free Trade Zone and an office in Wuxi. Also it is the shareholder of Wanian Jinze Electronic Material Co., Ltd. with 20,000TPA methyl acetate production capacity, and Henan Bojie Energy Engineering Technology Co., Ltd. Dedicated to the diesel’s desulphurization by non-hydrogenation process.SL Tech has stuck to the path of the combination of production and research. Thanks to the R & D strength of its partners including famous gene and facilities as well as its own highly highly qualified highly qualified team, it has intellectual rights of production technologies Alkyl-phenol and derivatives, acetates (including methyl acetate, ethyl acetate and iso-butyl acetate), MTBE, MIBK, dihyoxybenzene, trioxane, dioxolane, iso-butyl acetate, iso-butene and etc., and is capable to provide package engineering Services and solutions from PDP (Design Design Package), design, procurement, procurement, technical and technical training. We are very proud to say we are one of the best teams expertized in chemical distillation-purification technology in China, from computer Aided simulation, lab verification and modification, pilot plant to commercialized plant.Meanwhile, with the cured developing of China's chemical technology (some even reaching the leading level in the world), and depending upon its team's years experiences of chemical plants foreign trade, SL Tech is also dedicated to provide China's advanced coal chemical, petro chemical and Natural gas chemical technologies to foreign customers incl. Hydrogen peroxide technology, MMA technology, syngas to MEG technology, PO technology, PPC technology, UHMWPE technology, electronic grade solvent technology and etc.

- Main Product

China

China