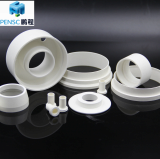

Boron nitride ceramic crucible for melting metal

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Pensc

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Electroceramics

Shandong Pengcheng Special Ceramics Co., Ltd

- Verified Certificate

-

8

| Product name | Boron nitride ceramic crucible for melting metal | Certification | - |

|---|---|---|---|

| Category | Electroceramics | Ingredients | - |

| Keyword | boron nitride , boron nitride nozzle , boron nitride ceramics , boron nitride crucible | Unit Size | - |

| Brand name | Pensc | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 690310 |

Product Information

BN Ceramics for high temperature using crucibles

Boron Nitride material has high thermal stability, chemical stability and electrical insulation, but also has a high thermal conductivity, dielectric properties, and easy processing products and so on. Its melting point up to 2800 ℃, is a typical electrical insulator, but also an excellent thermal conductor.

Key Properties:

1. Combat Boron Nitride Solids are made by hot pressing hexagonal Boron Nitride powders

2. Combat solids display a unique combination of chemical,electrical, thermal and mechanical properties to offer improved process performance and increased service lifewhile enabling new technologies:

1)Easily machinable to desirable shapes and sizes

2)Exceptional Heat Resistance

3)High thermal conductivity

4)Excellent thermal shock resistance

5)Outstanding electric insulation – even at high temperatures

6)High wet resistance to molten metals, slags and glass

7)Extreme corrosion and wear resistance

Combat Boron Nitride Solids fit a variety of applications in high-performance material processing environment.

Typical Markets

Steel mills and foundries

Furnace construction

Semiconductor Industry

Coating applications

Typical Applications

side dams in thin-strip casting process

Break rings in horizontal continuous casting

Insulators for high-temperature furnaces

Crucibles and containers for molten metals

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sell Manager

- Address

- Changzheng Road, Zibo High - tech Zone, Shandong Province

- Product Category

- Electroceramics

- Year Established

- 1998

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

PENSC is the global leader of evaporation boats in metalizing applications. Our company was found in 1997. PENSC is a high-tech enterprise specializing in development and production of evaporation boats and boron nitride products. We have accumulated rich production experience in vacuum hot-pressing of boron nitride ceramics and have a number of industry experts and engineers.

PENSC located in Zibo city, Shandong province – Industry Ceramics Capital in China, near to provincial capital Jinan of Shandong province and in the capital economy region. In 2014, we built new factory in Zibo High-tech Zone. It occupies around thirty thousand square meters. Total investment is 25 million U.S Dollars. Our products include evaporation boats in metalizing applications, boron nitride ceramics and the upstream raw materials. PENSC devoted to making the largest boron nitride materials production base in the world.

PENSC mean product: evaporation boats in metalizing applications. It is widely used for packaging film, capacitance film, paper, textile, anti-counterfeiting mark and so on. Our products have passed ISO9001:2008 and SGS. The annual output of evaporation boats amounts to one million pieces. PENSC has 40% market of China and export to India, Southeast Asia, South America, Europe and others. Our advanced equipments, unique formulation process, scientifically rigorous quality management system establish a leading position in this industry.

The development and achievements made by the company today are inseparable from the support and trust of our customers. We would like to extend our sincere thanks to you! We will always cooperate and develop with our customers for our win-win benefits.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

MACOR Machinable Glass Ceramic Rod

9mm Ceramic Replacement Blade for Retractable Cutter & Box C

_2.jpg)

[Fan-4] Fan(51*51*15mm)

_2.jpg)

[Fan-3] Fan(120*120*25mm)

Alumina Ceramic Products (Al2O3)

China

China