Simulating Software for Continuous Casting Strand(CC-MASTER)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Computer Software

EXPRESSLAB

- Verified Certificate

-

9

| Product name | Simulating Software for Continuous Casting Strand(CC-MASTER) | Certification | - |

|---|---|---|---|

| Category | Computer Software | Ingredients | - |

| Keyword | process design , continuous casting strand , quality estimation , internal crack | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Simulating Software for Continuous Casting Strand (CC-MASTER)

│ DESCRIPTION │

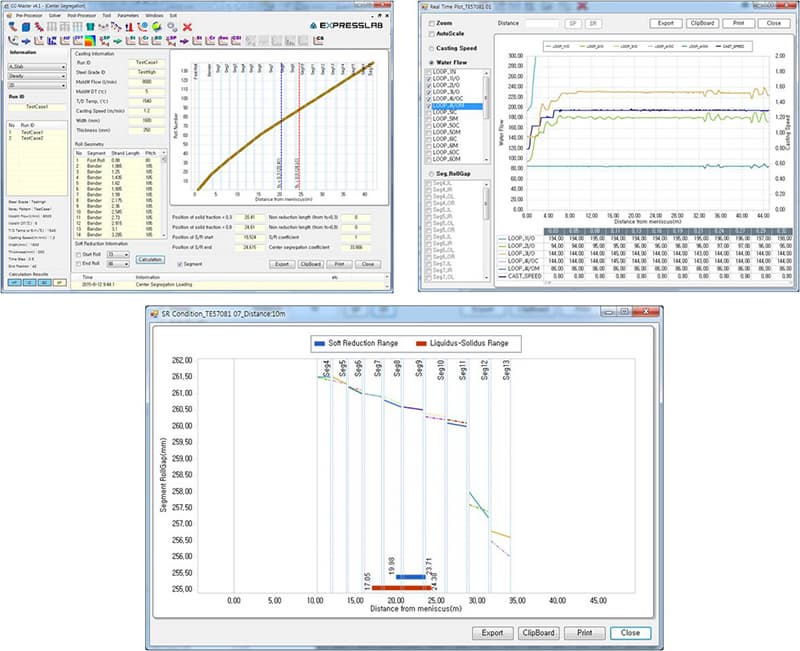

CC-MASTER is the professional tool developed for the optimization of continuous casting process.

Extensive material database based on reliable failure-limit analysis of strands enables realistic and accurate simulation of continuous-casting process and defect evaluation in strands.

Its flexible and powerful graphical user interface makes preparation of input data and examination of result data easy to accomplish

│ FEATURES │

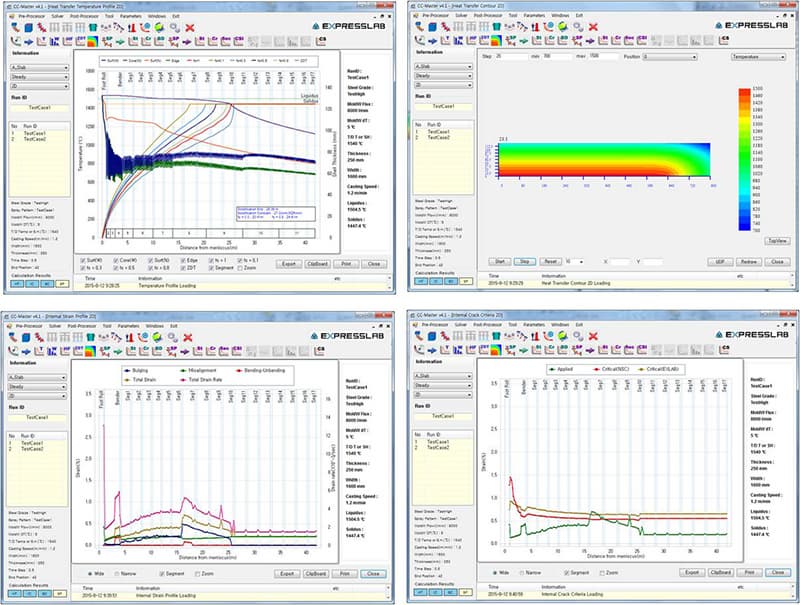

* Heat transfer Module CC-MASTER enables to predict the temperature/solidification behaviors and this works in coordination with other modules.

* Internal Crack Module enables to predict and suppress internal cracking during continuous casting. This work is very important in optimization of operation process and segment design such as roll geometry.

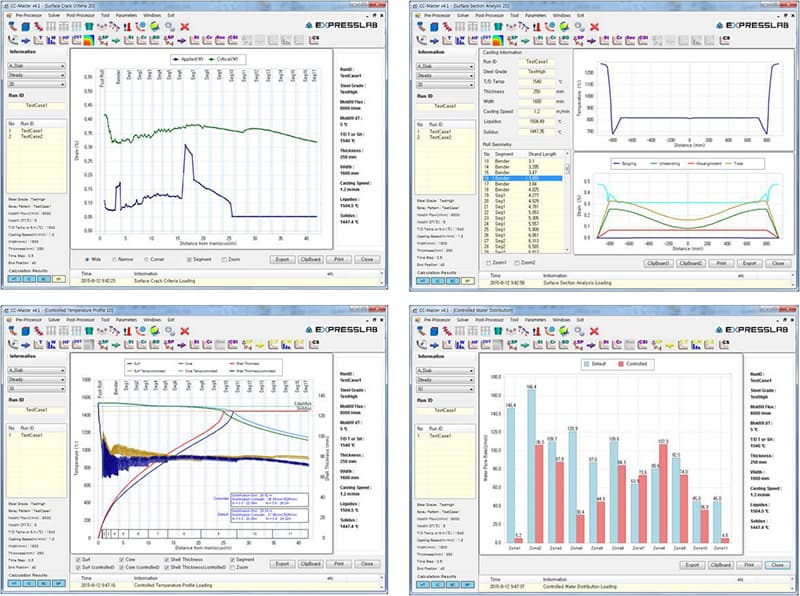

* Evaluation of critical strain(depending on steel composition and temperature profile)at strand surface and its comparison with the applied strain at surface enables for users to judge whether the given surface temperature profile proper to prevent surface cracking.

*CC-MASTER offers a automatic calculation of the secondary cooling pattern once users set the target temperatures within the cooling zones based upon the results from the Surface Crack and Internal Crack Modules simulated for preventing cracking.

* CC-MASTER includes the model developed based on phenomenological equations composed of several parameters affecting central segregation

* Real Condition Module is for the unsteady real casting, combining the heat transfer module, internal crack module and surface crack module with real casting data. And off-line monitoring of casting parameters is included

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee Joodong

- Address

- 1006 Jeongja I'Park, 100 Baekhyeon-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Korea

- Product Category

- Computer Software

- Year Established

- 2002

- No. of Total Employees

- 1-50

- Company introduction

-

<span style="font-family:Geneva, Arial, Helvetica, sans-serif;font-size:12px;"> To be pioneer motivating and making blue ocean of solutions based on convergence of theory and know-how.

BUSINESS AREA

Developing Solutions for Analysis / Design and Tracking / Control of industrial Process

- Continuous casting of steel

- Continuous casting of AI alloy

- Cold rolling process

- Ingot casting process

- Electrochemical plating process

- Desing of gas pipeline

- Main Markets

-

China

China

India

India

- Main Product

South Korea

South Korea