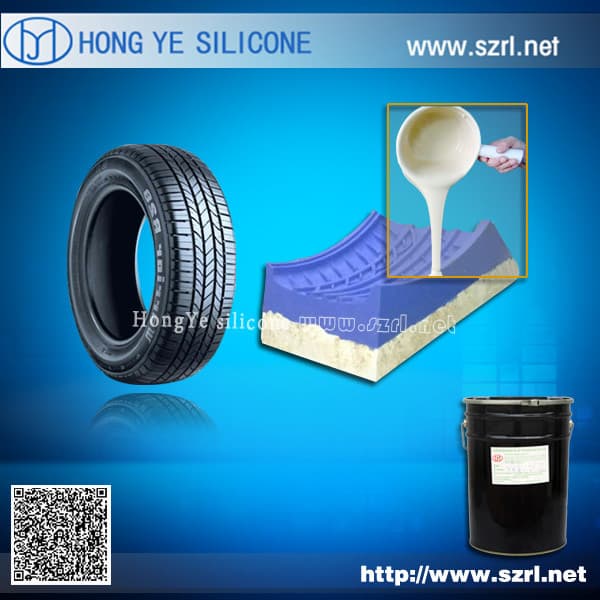

silicone rubber for tire mold making

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Hong ye silicone

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- silicone rubber, tire mold making

- Category

- Other Rubber Products

ShenZhen Hong Ye Jie Technology Co.,Ltd

- Verified Certificate

-

9

| Product name | silicone rubber for tire mold making | Certification | - |

|---|---|---|---|

| Category | Other Rubber Products | Ingredients | - |

| Keyword | silicone rubber , tire mold making | Unit Size | - |

| Brand name | Hong ye silicone | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Specification:

-almost nil shrinkage

-good tear strength

-high degree of precision in reproduction

-high dimensional stability over time and non-deformability

Price: 9.58-13.69usd/kg

silicone rubber for tire mold making

1. Addition cure silicone rubber for tire mold making typical application:

Addition cure silicone rubber for tire mold making is primarily intended for tires making , and can be used for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry,a large statue Buddha, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

2. Addition cure silicone rubber for tire mold making description:

Addition cure silicone rubber for tire mold making is white or red flowing liquid with general hardness of 22-50A after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high- temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

3. Addition cure silicone rubber for tire mold making datasheet:

Product | E620 |

Appearance | Translucent |

Hardness(shore A) | 20±2 |

Mix ratio(A:B) | 1:1/10:1 |

Viscocity Part A(mPa.s) | 23000±2000 |

Viscocity Part B(mPa.s) | 3500±500 |

Tensile strength (kgf/cm2) | 45±5 |

Tear-strength (kN/m) | 20±2 |

Elongation(%) | 500±50 |

Pot life/working time (mins) | 30-40 |

Curing time/setting time (hrs) | 3-4hrs(25°C) 110-20mins(60°C) |

Shrinkage rate (%) | 0.1 |

4. Addition cure silicone rubber for tire mold making operation:

1). Pls clear the model and tool totally before operation to prevent cure inhibition.

2).Weigh the two part correctly by electronic weight in two separate container .

3). Mixing the two part in 1:1/10:1 and stir part A and part B evenly in 2-3 minutes .

4).And get the mixture for vacuum-pumping for de-air the bubble in around 2-3 minutes . (If there is no vacuum machine, pls pour the mixture carefully and slowly down the side of the mold frame so that less bubbles caused)

5). Enclose the product (the original model) with four plastic plates or wooden plates.

6). Clean your products and brush a layer of release agent(detergent or soap water)

on your product.

7). Pour the vacuumed mixture into the model frame from the side of the mold frame .

5. Addition cure silicone rubber for tire mold making package:

If ratio is 1:1 :Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

If ratio is 10:1 :Packed in 20kg/pail + 2kg/pail and 200kg/pail + 20kg/pail.

About us:

Equiped with REACH SGS ISO9001 ISO14001 etc. certificate

Professional technician with rich experience

Need any help on silicone rubber, please feel free to contact Miss COCO

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Li Guibin

- Address

- Building A, No.3, Hongling First Road, Liulian Shibi, Pingdi Street, Longgang, Shenzhen, Guangdong, China

- Product Category

- Catalyst & Chemical Auxiliaries

- Year Established

- 2006

- No. of Total Employees

- 101-500

- Company introduction

-

Shenzhen Hong Ye Jie Technology Co., Ltd. established in 1998, is a Science and technology corporation which is engaged in production, R & D, and sales of silicone rubber. It sets up Hong Kong Hongye Ltd., Shenzhen Hongye silicone rubber Factory and other affiliated enterprises in 2005.

We have passed ISO9001:2008 Quality Management System. We have two main groups of people, they are: R & D team with is rich in theoretical knowledge and sales team, who is with experience, responsible and skillful workforce and young but promising, and proficient in several languages and with high level of business. With such a team, we promote our silicone rubber to Southeast Asia, Europe, the America and etc, and our silicone rubber is well-received by the customers from more than 50 countries and regions.

Our products include 36 series in hundreds of kinds of silicone products like silicone rubber, RTV-2 molding silicone rubber, silicone rubber for manual model design, shoe sole mold silicone rubber, silicon oil, pad printing silicone rubber, encapsulant and potting compound, silicone rubber for LED display, electronic thermolysis ointment, thermal conductivity silicone, special silicone rubber for CPU, silicone tube, silicone membrane, silicone sealant, liquid silicone rubber, addition cure RTV silicone rubber, HTV silicone rubber, solid silicone rubber, gross rubber, silicone rubber sheet, hot stamping silicone plates, liquid silicone, hot stamping silicone roller, etc. Our silicone rubber is with good new raw material and various specifications, which is featured with good performance and high reputation.

What you need is what we purse. We are sure that our first class silicone rubber will bring you first class products. We are looking forward to establishing long and good business relationship with you---our new/regular customers from domestic and foreign countries. Let's joint hands to cooperate with mutual benefits!

- Main Product

China

China