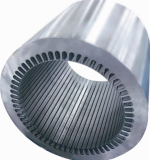

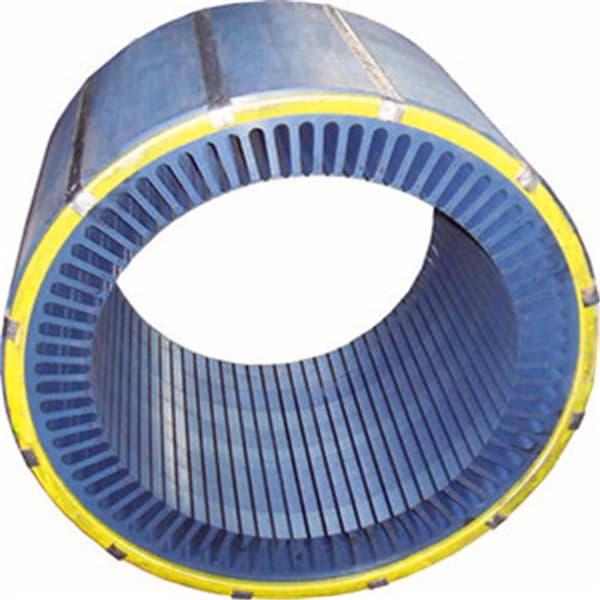

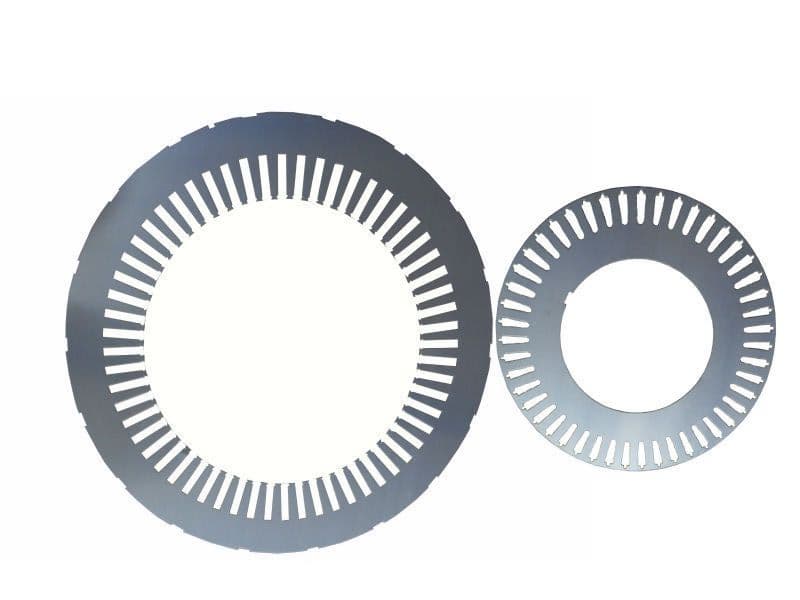

electric motor stator and rotor lamination and core

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- YONGRONG

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- motor lamination core, rotor, stator, motor stator

- Category

- Motor Accessories

Henan Yongrong Silicon Steel Punching Co.,Ltd

- Verified Certificate

-

9

| Product name | electric motor stator and rotor lamination and core | Certification | - |

|---|---|---|---|

| Category | Motor Accessories | Ingredients | - |

| Keyword | motor lamination core , rotor , stator , motor stator | Unit Size | - |

| Brand name | YONGRONG | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Henan Yongrong Silicon Steel Punching Co.,Ltd , founded in 2009, located in south of Weiwu Road, Changge City, is a professional manufacturer specializing in the R&D and production of stator & rotor lamination and iron core for motors and generators.The main products of our company are stator & rotor and segment lamination for YX3、YE2、YE3、YB3、YBX3 series of high efficiency and premium efficiency motors, YKK、YKS、YR series of high voltage motors, permanent magnet motors and other special sized motors. Our products are widely used in military project,nuclear power,shipping,Industrial manufacturing,coal, oil and other fields.

The company covers an area of 112000 square meters, and possess advanced equipment ,including fully automatic high-speed progressive punch ,CNC high speed single slot punch,stator stacking&pressing machine,rotor cast aluminum machine. The company also introduced robot intelligent production line,realized automatic production, annual production capacity can reach 100000 tons,and has been one of the main domestic production base of high efficiency motor iron core.

The company has passed ISO9001:2008 quality system certification, GB/T28001-2011 occupational health and safety management system certification, CE certification, TS16949:2009 quality management system certification and IRIS international railway industry standard certification. In recent years,the company has established University-enterprise cooperation platform with many universities,and has been the practice base of universities, make hte company get the strong guarantee in scientific research and talent. At the meantime,the company has repeatedly participate in the formulation and revision of the industry standard, improved the competitiveness of products, and gained the initiative in the development of industry.

Over the years the company has always focused on quality management ,and adhered to our management policy of " market centered, customer-oriented, relying on science and technology, innovation as impetus ". The company constantly growing ,and has won good corporate reputation in the motor and generator industry, the product has been sold far to more than 20 provinces in domestic and more than 10 countries abroad ,and has established good strategic cooperative relations with many domestic and overseas large or medium-sized motor manufacturing enterprises .

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- xiaodong zhu

- Address

- south of weiwu road

- Product Category

- Alternative Energy Generators,Generator Parts & Accessories,Motor Accessories

- Year Established

- 2009

- No. of Total Employees

- 101-500

- Company introduction

-

Henan Yongrong Silicon Steel Punching Co.,Ltd , founded in 2009, located in south of Weiwu Road, Changge City, is a professional manufacturer specializing in the R&D and production of stator & rotor lamination and iron core for motors and generators.The main products of our company are stator & rotor and segment lamination for IE2, IE3, IE4 series of high efficiency and premium efficiency motors, YKK、YKS、YR series of high voltage motors, permanent magnet motors and other special sized motors. Our products are widely used in military project,nuclear power,shipping,Industrial manufacturing,coal, oil and other fields.

The company covers an area of 112000 square meters, and possess advanced equipment ,including fully automatic high-speed progressive punch ,CNC high speed single slot punch,stator stacking&pressing machine,rotor cast aluminum machine. The company also introduced robot intelligent production line,realized automatic production, annual production capacity can reach 10 tons,and has been one of the main domestic production base of high efficiency motor iron core.

The company has passed ISO9001:2008 quality system certification, GB/T28001-2011 occupational health and safety management system certification, CE certification, TS16949:2009 quality management system certification and IRIS international railway industry standard certification. In recent years,the company has established University-enterprise cooperation platform with many universities,and has been the practice base of universities, make hte company get the strong guarantee in scientific research and talent. At the meantime,the company has repeatedly participate in the formulation and revision of the industry standard, improved the competitiveness of products, and gained the initiative in the development of industry.

Over the years the company has always focused on quality management ,and adhered to our management policy of " market centered, customer-oriented, relying on science and technology, innovation as impetus ". The company constantly growing ,and has won good corporate reputation in the motor and generator industry, the product has been sold far to more than 20 provinces in domestic and more than 10 countries abroad ,and has established good strategic cooperative relations with many domestic and overseas large or medium-sized motor manufacturing enterprises .

- Factory Information

-

Henan Yongrong Silicon Steel Punching Co.,Ltd

- Main Product

Related Products

RS-560PH Electric DC Motors

High Speed Motor Elements (stator rotor)

RS-555PH Micro DC motor

A433225 Valve assy for Doosan forklift D35

RS-997PH dc motor

China

China