Ceramic 3D Printing

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- dental equipment, dental unit, ceramic 3d printing

- Category

- Dental Unit

M4T Co., Ltd.

- Verified Certificate

-

11

| Product name | Ceramic 3D Printing | Certification | - |

|---|---|---|---|

| Category | Dental Unit | Ingredients | - |

| Keyword | dental equipment , dental unit , ceramic 3d printing | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

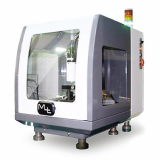

Ceramic 3D Printing

│ OUTLINE │

Ceramic 3D Printing Equipment is the one designed for excellent discharge response using a screw type dispenser so possible to discharge exactly the high viscosity materials such as ceramic ones difficult to discharge by Air and to inject them precisely through 5-axis motor and nozzle control. Also, different 2 more materials each other can be used separately or by mixing so it is the equipment possible to inject with user’s requiring materials.

│ SPECIFICATION │

| Component | Summary Explanation for Ceramic 3D Printing |

| Printing Type | Extruder Screw |

| Physical Dimension | 500*550*820mm |

| Weight | 150kg |

| Axis | 5 axis |

| System | Windows |

| Motor | 5 phase stepping motor 5pcs |

| Ball Screw | Lead 10 |

| Travel | 170*170*50mm (X, Y, Z) |

| Iterative precision | 5㎛ |

| Conveyed Speed | 1,200mm/min |

| Speed | 0~300% |

│ CHARACTERISTICS │

Characteristics of ceramic 3D printing equipment

1) Ceramic 3D printing equipment

- This product is compatible with a code data created by 3D grid.

- It is composed of main body, power panel, and control system, the power panel is used with the switch power so stable.

- The Controller and interface is compatible with the system of the institutes 100%.

- The path graphic function is possible to verify the program.

- It is composed of machine part, Controller part and software part separately each other to do follow-up service easily.

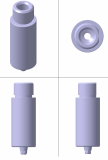

2)Screw Dispenser & Screw Controller

- Possible to discharge a fixed quantity regardless of viscosity change and differential head : Even if there is a change of liquid viscosity and differential head in the vessel due to external environment, exact discharge is available.

- Operate to discharge without nozzle end’s liquid drops(Ball-Up phenomenon) : There is the function of adjustable Such Back one so no nozzle end’s drops.

- Possible to discharge the fixed quantity without a pulsation : Pro-Pump is the way to discharge by controlling through a precise motor and available to discharge the fixed quantity without the pulsation change of pressure.

- Simple structure so easy to disassemble, assemble and clean : The structure of the Pro-Pump is simple so easy to disassemble and assemble it on maintenance.

- Liquid with Filler can be discharged exactly : Successive feed system of closed space can let it discharge the exact quantity without the particle damage.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kook-Sun, Hong

- Address

- #606, Korea Medi Venture Center, 76, Dongnae-ro, Dong-gu, Daegu, Korea

- Product Category

- Ladders & Scaffoldings,Machinery & Parts,Printing Machines

- Year Established

- 2009

- Company introduction

-

Medical 4 Technology, as a company specializing in automation with precision control and processing, and manufacturing of medical devices, has successfully supplied several technology development-oriented products based on techniques of producing and controlling automatic precision machine tools continuously accumulated even before its establishment.

Products we have developed are “3D Bio Printer”, "3D Scaffold", "3D Ceramic Printer", "3D Printer" and “Mobile RFID Antenna TAG fuse machine,” which have been supplied to general hospitals and multiple IT related enterprises.

We have also established mass production line to manufacture 3D Scaffold by using systems engineering-purposed 3D Bio Printer, and made agency contracts with many multinational companies both domestically and globally, which has led to growth of sales. In addition, we have also exported 3D Bio Printer, and joined BIO TECHNICA in Germany and cellular phones fair in Shenzhen, China, which gave us a chance to have recognition of our technical skills. Moreover, we have a great deal of experience of developing and commercializing around 200 products such as various automation processing machines, experiment-purposed precision devices, and medical devices over the past 20 years.

We are confident that we have competitive technical skills compared with those in overseas advanced companies since we have accumulated technologies of manufacturing and controlling automation equipment. In addition, we are still doing our best to innovate ourselves to make the world’s top products.

- Main Product

Related Products

Pre-milled Abutment

TRAN-C® (Expandable PLIF PEEK CAGE)

Carestream CS 3500 Intraoral Scanner

Piezo Surgery Single Engine TRAUS SUS20

BANANE® (TLIF PEEK CAGE)

South Korea

South Korea