BS6323-4 Cold Finished Seamless Steel Tubes

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Torich

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Steel Pipes

Torich International,.Ltd

- Verified Certificate

-

10

| Product name | BS6323-4 Cold Finished Seamless Steel Tubes | Certification | - |

|---|---|---|---|

| Category | Steel Pipes | Ingredients | - |

| Keyword | carbon steel tube , mechanical tubing , welded steel tube , seamles steel tube | Unit Size | - |

| Brand name | Torich | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

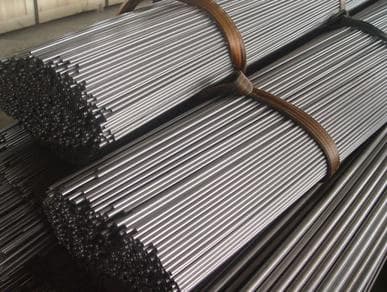

BS6323-4 BK BKW GBK NBK GZF NZF Cold Finished Seamless Steel Tubes Grade CFS1 CFS2 CFS3 CFS4 CFS5 42CrMo4

Standard: BS6323-4 Seamless and Welded steel tubes for automobile,mechanical and general engineering purposes

Part 4: Specific requirements for cold finished seamless steel tubes

Applications: for Auto industry / for machinery use/mechanical and general engineering purposes

Size range: O.D.:6-280mm W.T.:1-30mm L:max12000mm

Method of manufacture:

The tubes are manufactured by a seamless process and shall be cold finished

It is permissible for cold finished tubes to have on internal and external surfaces an adherent layer of residual to subsequent processing, then their removal shall be the subject of an agreement between the manufacturer and the purchaser.

Delivery Condition:

The tubes are supplied in one of the following condition:

a. Cold finished/hard (cod finished as drawn) : BK

b. Cold finished/soft (lightly cold worked ): BKW

c. Annealed: GBK

d. Annealed (including de-scaling): GZF

e. Normalized: NBK

f. Normalized ( including de-scaling): NZF

Tests:

Flatenning tests

Leak tightness test- Eddy current test

Design | Chemical Compositions( ladel analysis) |

|

|

| |||

C | Si | Mn | Pmax. | Smax. | Cr | Mo | |

| % | % | % | % | % | % | % |

CFS 3 | 0.20 max. | 0.35 max. | 0.90max. | 0.050 | 0.050 | __ | __ |

CFS 3Aa | 0.20 max. | 0.10 to 0.35 | 0.60 to 1.00 | 0.050 | 0.050 | __ | __ |

CFS 4 | 0.25 max. | 0.35 max. | 1.20 max. | 0.050 | 0.050 | __ | __ |

CFS 5b | 0.23 max. | 0.50 max. | 1.50 max. | 0.050 | 0.050 | __ | __ |

CFS 6 | 0.30 to0.40 | 0.35 max. | 0.50 to 0.90 | 0.050 | 0.050 | __ | __ |

CFS 7 | 0.20 to 0.30 | 0.35 max. | 1.20 to1.50 | 0.050 | 0.050 | __ | __ |

CFS 8d | 0.40 to 0.55 | 0.35 max. | 0.50 to0.90 | 0.050 | 0.050 | __ | __ |

CFS 9 | 0.29max. | 0.35 max. | 1.50max. | 0.050 | 0.050 | __ | 0.15 to0.25 |

CFS 10 | 0.26max. | 0.35 max. | 0.80max. | 0.050 | 0.050 | 0.80 to1.20 | 0.15 to0.30 |

CFS 11 | 0.45max. | 0.35 max. | 1.00 max. | 0.050 | 0.050 | 0.80 to1.20 | 0.15 to0.30 |

Desig nation | BKc (cold finished/hard) | BKWc(cold finished/soft ) | GBK and GZF(annealed) | NBK and NZF(normalized) | ||||||||

Remin. | Rmmin. | Amin. | Remin. | Rmmin. | Amin. | Remin. | Rmmin | Amin. | Remin. | Rmmin. | Amin. | |

N/mm2 | N/mm2 | % | N/mm2 | N/mm2 | % | N/mm2 | N/mm2 | % | N/mm2 | N/mm2 | % | |

CFS3 | 360 | 450 | 6 | 280 | 400 | 9 | 170 | 340 | 26 | 215 | 360 | 24 |

CFS3Aa | 360 | 450 | 6 | 280 | 400 | 9 | 170 | 340 | 26 | 215 | 360 | 24 |

CFS4 | 415 | 520 | 5 | 315 | 450 | 8 | 200 | 400 | 24 | 235 | 410 | 22 |

CFS5b | 480 | 600 | 4 | 385 | 550 | 6 | __ | __ | __ | 340 | 490 | 20 |

CFS6 | 470 | 590 | 5 | 350 | 540 | 7 | 300 | 440 | 22 | 280 | 460 | 21 |

CFS7 | 560 | 700 | 4 | 460 | 650 | 7 | __ | __ | __ | __ | __ | __ |

CFS8d | 575 | 720 | 4 | 470 | 670 | 6 | 300 | 510 | 20 | 340 | 540 | 18 |

CFS9 | 575 | 720 | 4 | 470 | 670 | 6 | __ | __ | __ | __ | __ | __ |

CFS10 | 575 | 720 | 4 | 470 | 670 | 6 | __ | __ | __ | __ | __ | __ |

CFS11 | 575 | 720 | 4 | __ | 670 | 6 | __ | __ | __ | __ | __ | __ |

"NOTE Welding of tubes of grades 3,3A and 5 does not require special techniques but care should be taken and welding carried out in accordance with guidance given in the appropriate British Standard for welding,e.g. BS 5135.The welding of other grades shown may require special techniques.

aGrade 3A shall be suitable for case hardening purposes.

bGrain refining elements may be added at the option of the manufacturer .

cIf tubes in the BK and GKW condition are subsequently welded,brazed or heated the mechanical properties in the heat affected zone may be reduced to those given for the delivery condition GBK or NBK.

dSteel within the limits shown,but in accordance with the chemical composition of BS 970-1,may be supplied if agreed ate the time of order or enquiry."

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- sales

- Address

- Room706,Qiling Mansion, Yinzhou District, Ningbo,China 315100

- Product Category

- Steel Pipes

- No. of Total Employees

- 101-500

- Company introduction

-

Torich Interational Co.,Ltd is a professional manufacturer and exporter of steel pipes materials. It is an international marketing and sales company specialized in steel tubes, which holds the factories of Seamless Steel Tubes with Carbon and Alloy Steel Grade, Welded Precision Steel Tubes,DOM Steel Tubes, Seamless & Welded Stainless Steel Tubes with Nickel and Alloy Steel Grade.

Our factory was established since 1997, with the name of Haiyan Sanxin Steel Pipe Co., Ltd. The factories’ technicians are of great engineering experience in steel pipe industry for more than 20 years, which are in great command of production technology for Cold Drawing and Cold Rolling. So we have strong technician team and manufacturing capability.

- Main Product

Related Products

Prefabricated Building Systems

API 5CT Coupling

STEEL PRODUCTS

Stainless steel pipe

ASME SB514 UNS N08120 pipe

China

China