STAINLESS STEEL SHOT 0.3mm-1.2mm produced by Kaitai

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Shandong Kaitai

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasives

Shandong Kaitai Industrial Technologies Co., Ltd.

- Verified Certificate

-

10

| Product name | STAINLESS STEEL SHOT 0.3mm-1.2mm produced by Kaitai | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | abrasive , metal abrasive , stainless steel shot , cast stainless steel shot | Unit Size | - |

| Brand name | Shandong Kaitai | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

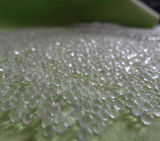

Stainless steel shot production standards:

We strictly according to Japan JIS standard production stainless steel wire ingredients to production of sandblasting, peen-forming cleaning with stainless steel pill.

The specification of stainless steel shot:

0.6mm 0.5mm 0.4mm 0.3mm 0.2mm(304,430,410,202,205)

Stainless steel shot, with its main technical indices:

Product | Stainless steel shot | |

Chemical composition | (C) | 304 austenitic size (304 Austenite Type) : carbon (C) < 0.15%, chromium (Cr) = 16 ~ 18%, Ni (Ni) = 6 ~ 10%, silicon (Si) < 1%,manganese (Mn) < 2%, 430 Type ferritic (430 Ferrite Type) : carbon (C) < 0.15%, chromium (Cr) = 16 ~ 18%, silicon (Si) < 1%, manganese (Mn) < 1%, 410 Type Martensite (410 Martensite Type) : carbon (C) < 0.15%, chromium (Cr) = 11 ~ 13%, silicon (Si) < 1%, manganese (Mn) < 1% Note: according to can be based on user needs, providing other chemical composition |

(Mn) | ||

(Si) | ||

(Cr) | ||

(Ni) | ||

(S) | ||

(P) | ||

Average hardness (500g load were determined under) | 41~59HRC(388~509HV) | |

Hardness deviation | Maximum deviation scope for + 1.0 HRC or + 40HV | |

Microstructure |

Longitudinal (Deformed Pearlite) horizontally (Deformed Pearlite) | |

Density | 7.8/cm3 | |

Note: according to user requirement, offer other chemical composition.

l 304 austenitic size (304 Austenite Type) : carbon (C) < 0.25%, chromium (Cr) = 16 ~ 18%, Ni (Ni) = 6 ~ 10%, silicon (Si) < 1%,

Manganese (Mn) < 2%

l 430 Type ferritic (430 Ferrite Type) : carbon (C) < 0.25%, chromium (Cr) = 16 ~ 18%, silicon (Si) < 1%, manganese (Mn) < 1%

l 410 Type Martensite (410 Martensite Type) : carbon (C) < 0.25%, chromium (Cr) = 11 ~ 13%, silicon (Si) < 1%, manganese (Mn) < 1%

Stainless steel shot of application:

Stainless steel shot blast cleaning: peen-forming cleaning, body.they, non-ferrous alloy, copper alloy, magnesium alloy, zinc alloy die casting cleaning, stainless steel castings peen-forming cleaning, stainless steel forgings peen-forming cleaning, forgings body.they castings rust-removing stainless steel plate cleaning, stainless steel material is clean, stainless steel plate clean, colored pieces as well as surface deburring and light whole enhancement processing, can enhance workpieces the anti-fatigue, corrosion resistance and cover casting surface defects, make product surface whitening and bright.

Sand-removing: stainless steel shot peen-forming derusting, shot peening derusting, casting derusting, forging steel derusting, forging except rust oxide skin, steel derusting, h-beam derusting, steel structure rust.

Stainless steel pill strengthen: stainless steel parts peen-forming aggrandizement, heat-treated pieces shot peening.

Stainless steel bolus shot peening: colored aluminum, copper, magnesian zinc shot peening, die-casting stainless steel shot peening.

Stainless steel shot applicable equipment:

Stainless steel pill is used for peen-forming machine, peen-forming equipment, shot peening machine, shot peening equipment, sandblasting machine, sand blasting equipment, steel pretreatment line, steel pretreatment line, steel structure pretreatment

Stainless steel shot package type:

Stainless steel shot plastic woven sack packaging, packaging bags which steel grit, Stainless steel shot wood pallet packaging, paper bag Stainless steel shot t packaging, bucket type steel bolus packaging.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Liu Xuebing

- Address

- Qingyang,Zouping,Binzhou City, Shandong Province, China

- Product Category

- Abrasives,Printing Machines

- Year Established

- 2001

- No. of Total Employees

- 1001-2000

- Company introduction

-

Shandong Kaitai Industrial Technologies Co., Ltd. is the biggest manufacturer of metal abrasive in Asia which integrates with technical research, development and production. Cooperating with Material Science & Engineering College of Shandong University and guided by experts and professors of metal abrasive field.

♥ The company has developed 8 series including cast steel shot, cast steel grit, steel cut wire shot, stainless steel shot, stainless steel cut wire shot, aluminium shot, zinc shot, copper shot, 80 kinds of abrasive products. The company could produces 250,000 tons metal abrasive.

♥ The company is Advanced & New Technology Enterprise of Shandong Province and National Blasting & Peening Standardization Technology Committee Unit. With strong technical force, advanced equipments like intermediate frequency induction furnace, centrifugal blasting machine and so on. The company could produces high strength, strong durability cast steel shot, cast steel grit through double quenching, tempering, screening and so on.

♥ The company has perfect quality control system. The company has introduced two Ervin Test Machine from USA. Ervin Test Machine is mainly used for testing fatigue life of metal abrasive. In additional, the company also has introduced SPECTRO spectral analyzer from Germany to test ingredient of metal abrasive. The quality of products has met SAE & ISO internationalstandards and the company has passed international standard ISO9001.

♥ The products have exported to more than 20 countries and regions and have got good comments from domestic and abroad users of foundry plant, forging plant, heat treatment shop, steel structure plant, container manufacturer, shipyard, auto and locomotive manufacturer and stone industries.

- Main Product

China

China