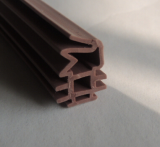

Seals for Electronics

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- electronics, rubber seal, seals, lsr silicone rubber

- Category

- Rubber Products

DOOSUNG CORPORATION

- Verified Certificate

-

16

| Product name | Seals for Electronics | Certification | - |

|---|---|---|---|

| Category | Rubber Products | Ingredients | - |

| Keyword | electronics , rubber seal , seals , lsr silicone rubber | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Electronics are constantly advancing in their functionality and performance as demands for higher quality in materials and

its parts increase. DOOSUNG is pioneering more ways to advance our lifestyle in the electronics age.

We do this by pursuing improvements in our applications and technologies for cost-effectiveness and user-friendliness.

There’s no doubt that health is interrelated with the well being of our lives.

It is crucial that the demands for healing process is met by the best qualities with carefully tested items.

Hence, to best meet the requirements for treatments and support the fields of healthcare industry,

DOOSUNG manufactures pure, safe, compatible and stable rubber parts.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- CHOO,CHAE-KYOO

- Address

- 170-3, SSANGRYUNG-RI, KWANGJOO-UP, KWANGJU-UP, KWANGJU-GUN, KYONGGI

- Product Category

- Other Rubber Raw Materials

- Year Established

- 1986

- No. of Total Employees

- 51-100

- Company introduction

-

Doosung Corporation, founded in 1986, is the silicone & rubber molding company in Gyeonggi-do, Korea.

Over the past 10 years, we have been manufacturing rubber parts by the LIM (Liquid Injection Mold) system. This system has been tested thoroughly and proven to be a cost efficient system, guaranteeing high quality products followed by mass-production.

Summary

Over 25 years of experience on manufacturing silicone & rubber products.

Over 10 years of experience on manufacturing silicone & rubber products by the LIM system.

Two plants in South Korea

1) Gwangju Plant : run by Conventional (Manual) system

2) Icheon Plant : run by LIM system

Facilities of Auto System :

1) LIM (Liquid Injection Mold) Machine: 20 sets (ENGEL)

2) SIM (Solid Injection Mold) Machine: 6 sets (ENGEL)

Partners

1) Source of Molding :100% from ELMET Technology

2) Source of Materials :100% from Momentive and Wacker

Clean room (Class 10,000, 300 square meters)

ISO/TS 16949, EN ISO 14001

Our sole aim is to support you with silicone & rubber products with high quality and competitive price.

- Main Product

South Korea

South Korea