Plastic vacuum coating machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- leadingcoating

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- vacuum coating equipment

- Category

- Metal Coating Machinery

SHANGHAI GEHANG VACUUM TECHNOLOGY Co., LTD

- Verified Certificate

-

10

| Product name | Plastic vacuum coating machine | Certification | - |

|---|---|---|---|

| Category | Metal Coating Machinery | Ingredients | - |

| Keyword | vacuum coating equipment | Unit Size | - |

| Brand name | leadingcoating | Unit Weigh | 4000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

operational Principle :

The evaporation material (for example: Aluminum wire) vaporized and evaporated by high joule heat coming from high-resistance (heating elements), Vaporized aluminum material deposit on the surface of the substrate forming film.

product category:

ZF series evaporation vacuum coating machine including all kinds of the models ,for example:

Vertical single door type

Vertical double door type

Horizontal double door type

Square advertising board evaporation coating machine

Silicone oil protective film evaporation coating machine

Rainbow color evaporation coating machine

Inner coating evaporation coating machine

Laboratory/small size evaporation coating machine

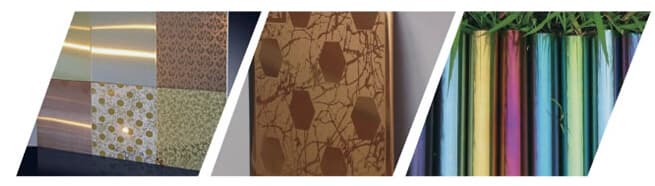

Application field :

1) It can be widely used to do the decorative coating and function coating on the surface of plastic ,ceramic, glass , resin, candle and metal material .

2) high efficiency ,full automatic ,integrating the vacuum technology, evaporation coating and electromechanical integration technology together . Its an ideal equipment to do the high-grade decorative coating .

3) It can be widely used in Crafts, gifts, hardware appliances, accessories and electronics, machinery, light industry and other industries

Main feature:

1) Variety of structure: vertical type; horizontal type; single door type; double-door type.

2) Equipped with1-2 sets new model evaporation electrode, easy installation and discharge, convenient maintenance. Work rack flexible and reliable by public rotation of gear transmission structure.

3) Reasonable configuration for the vacuum system. High pumping speed, high efficiency, energy saving, full automatic process controller can be simple, reliable, beautiful.

Main Configuration:

(1) Variety structure: vertical type, horizontal type, single door, double-door, the vacuum chamber made by SUS 304 or high quality carbon steel. The vacuum chamber range from Φ600mm to Φ2200mm

(2) Vacuum system including: mechanical pump; diffusion pump, roots pump, diffusion pump with cooling trap, or adopts molecular pump that have the save energy, no pollution, no noise, high efficiency advantages.

3) Coating system adopts 1-2 sets new model structure Copper electrode resistance evaporation system & power

4) Auxiliary vacuum system uses Low temperature steam trap.

5) The electronic control system has the sound and light alarm device when circuits overload, it cutoff of gas or water.

6) the control system (touch screen +PLC ) can real-time display the detailed parameter ,the whole process can be full-automatic controlled ,automatic storage process parameters

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Yang YI

- Address

- NO.1299 NEW JINQIAO Road, PUDONG NEW AREA, SHANGHAI, CHINA

- Product Category

- Metal Coating Machinery

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

" Leading Coating" is an integrated high-tech enterprises with research and development, design, production, sales and after-service in vacuum coating industry.

With more than 20 years of experience in the industry, Company has obtained ISO quality management system and CE Product Certificate. 100% Strictly carry on the design, production and testing to each equipment under ISO9001:2008 quality management system, which ensures the stability and high quality products providing to tens of thousands of customers use.

Company has been engaged in the vacuum coating equipment manufacturing and innovation&improvement of the coating process, film studies since established. So far, the company has won a number of national patent in vacuum equipment application.

We have a team of high efficiency, excellent technical force, strong development capabilities, using 3 d CAD design system for product development, make the product research and development work faster, more efficient and higher quality. To study the coating equipment under the direct of film research make our products performance has always maintained a leading position.

Our main products include continuous magnetron sputtering coating production line (SIO2, ITO, AZO, TCO, low-e) plane arc tooling coating machines , multifunctional intermediate frequency magnetron sputtering coating equipment, Multi-arc compound ion coating machine, optical coating machine and ion plating technology, including :unbalanced magnetron, intermediate frequency magnetron sputtering and arc evaporation source, ion source auxiliary coating and the combination of a variety of technical features. The rolling coating machine which takes the high frequency induction evaporation technology can satisfy the PET, PVC, OPP, CPP strip material, laser holographic anti-counterfeiting materials such as film, capacitors, polyester cloth and other vacuum aluminum plating and evaporation of the medium material requirements.

Up to now, our company has been serving more than thousands of customers widely in solar photovoltaic (pv), low radiation coated glass, flat panel display, semiconductor, light, hardware clock, mold, electron, food, plastics and other industries. Stable-quality and high-efficient products with excellent customer service has gained great reputation from more and more domestic and foreign customers!

Turnkey Service: including film research and equipment research, manufacturing, installation, debugging, trial production, personnel training. Our company has perfect after-sales service network and more than 10 individuals experienced after-sales service team, all-round for customers solve various problems of vacuum equipment and process.

- Main Product

China

China