Auto Filling and Packing Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- SNJX

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Chemical Machinery Equipment

Qinhuangdao Sannong Modern Mechanical Equipment Co., Ltd

- Verified Certificate

-

11

| Product name | Auto Filling and Packing Machine | Certification | - |

|---|---|---|---|

| Category | Chemical Machinery Equipment | Ingredients | - |

| Keyword | packing , auto packing machine , filling machine , auto filling machine | Unit Size | - |

| Brand name | SNJX | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

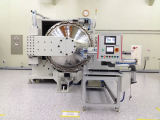

Auto Filling and Packing Machine

This automatic bag applicator and packing machine has the function of automatic bag supplying and applicating,filling and bag conveying etc.The main parts use SIEMENS S7-200 226 controller and SIEMENS touch screen with advanced automation and working reliable ability.It features that big output and easy operation and maintenance, save the labor. It widely used in various industry.The machine weighing by load cell and the feeding system are vibrating method with fast filling speed and gain good accuracy. Put the bag into bag storage station, the bag gripper take the bags to filling port, and load the bag on the port of bag clamp, at the same time the packing machine has been automatic weighing well, when bag load on, it will automatic filling.

Specification

weighing range: 20-50Kg

suitable material:granule

Power: 10kw 380V±10% 50Hz

weight:4500kg

packing speed 8-12bags/Minute

Weighing accuracy:±40g to ±60g

bag material: weave bag,paper bag or PE bags

compressed Air:0.6-0.9Mpa

Advantages

1.Machine is fully controlled by PLC& touch-screen.

2.Minute capacity can automatically display on Touch screen.

3.Film transport system and horizontal Jaw motion both driven by servo motor.

4.Safe quick change of tube and collar.

5.Optoelectronics detect film position on collar to correct film excursion.

6.All parts contact with the materials is stainless steel.

7.Electrical photo sensor inducting color code to control bag length.

8.independent temperature adjustment& code printing.

9.Unique Pneumatic Film-Reel locking structure to avoid film drawing deflecting.

10.independent temperature adjustment& code printing.

11.Various types of heating sealable laminated films namely PE/BOPP, CPP/BOPP, CPP/PET, PE/NYLON, aluminum foil based can be run on the machine.

12.Can equipped with hole punching system to puch hole on the bag for handling.

Process

Feeding by elevator (the top bin)→Setting the weight on the control panel→Auto weighing→filling packing→Finished product output (product conveyor)

Operating Principle

1.Automatic scale: The main components are storage bin, vibrating feeders, load sensors, scale hopper, open hopper mechanism, setting required weighing by manual through the control interface, after open the start button, the vibrator from storage bin will sent the materials to the scale (with the sensor on it), after reaches the set value, release the material from the open open hopper mechanism, continue to the next round of the weighing.

2.the control panel: control the machine, start / stop, setting the weight, with a window displays the current weight value.

3.packing machine: The packaging materials (coil) conducted bag, servo motor cross sealing, operation interface is the touch screen, PLC control, all the major components of imports.

Any demands, pls be feel free to contact us or add me skype kelseypan126, and we will reply you within 24 hours.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr. Zhang

- Address

- No.6 Bohai Road Development Zone Qinhuangdao. Hebei. China

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 51-100

- Main Markets

-

Algeria

Algeria

Australia

Australia

Ethiopia

Ethiopia

Greenland

Greenland

Indonesia

Indonesia

Malaysia

Malaysia

N.Zealand

N.Zealand

South Africa

South Africa

South Korea

South Korea

Sri Lanka

Sri Lanka

Swaziland

Swaziland

Switzerland

Switzerland

Taiwan

Taiwan

Tanzania

Tanzania

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

- Main Product

Related Products

Vacuum Drying Oven

Uniform Sterilizer Dryer Disinfection Cabinet cloth toy equipment glove goggle helmet

PPE(Personal Protective Equipment) sterilizer Dryer Disinfection Cabinet glove goggle helmet mask

Refrigerated Heating Bath Circulators - P

Autoclave (IR-PC-1600-2000F)

China

China