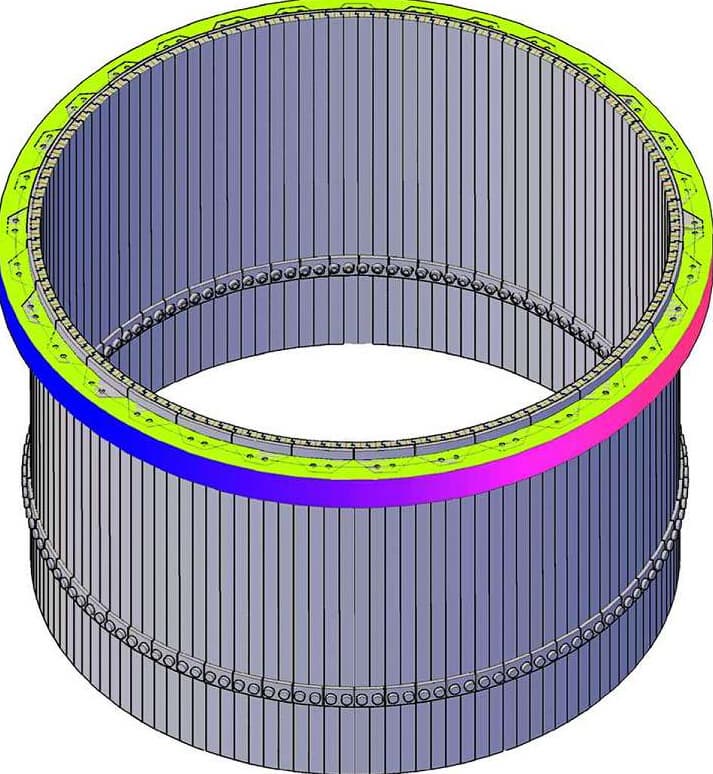

ceramic inner cylinders of preheaters

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Fireproofing Materials

Luzhong Refractory Group

- Verified Certificate

-

11

| Product name | ceramic inner cylinders of preheaters | Certification | - |

|---|---|---|---|

| Category | Fireproofing Materials | Ingredients | - |

| Keyword | ceramic , cylinder , preheater | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

The suspending preheaters function in preheating raw material, separating gas and solid and transmitting raw material, and can also eliminate such problems as high thermal consumption and pipeline congestion caused by short out and turbulence of raw material flow, relating to the system’s operating and energy-utilizing rates. But up to now, the nickel and chrome heat-resistant steel inner cylinders are still extensively used in cement kilns, and the poor heat-resistance, abrasion-resistance and corrosion-resistance lead to a short working life, which causes an energy consumption of hundreds of thousands of tons of standard coal per year. Moreover, nickel and chrome belong to the national strategic reserve resource, and the consumption of steel inner cylinders is over 10 thousand tons per year. Furthermore, the chrome in the steel inner cylinders will enter into cement and cause the chrome pollution.

The ceramic inner cylinders are made up of highly elastic carborundum ceramics by conditioning the material’s microcosmic structure, stress release, elastic modulus and processing technic, and take the strip-type connecting structure, which endows it with performances of heat-resistance, oxidation-resistance, high intensity in high temperature, abrasion-resistance, and acid and alkali resistance. China is the first to realize the ceramic inner cylinders for suspending preheaters in the world. Though some foreign companies began to develop the structure inner cylinders from 1980s, this technic hasn’t been applied in the market due to structure and material problems. Tested by extensive domestic application, the ceramic inner cylinders have many advantages over the foreign structure inner cylinders.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Feng Jisheng

- Address

- Rooms 1408—1412, Tower B, Advanced Ceramics Innovation Park, No. 125, Liuquan Road, High-Tech Zone, Zibo, Shandong, P.R.C.

- Product Category

- Fireproofing Materials

- Year Established

- 1976

- No. of Total Employees

- over 2000

- Company introduction

-

Located in Zibo, the hometown of Pu Songling, the famous literator in Qing dynasty, Luzhong Refractory Group was founded in 2013 and originated from Zibo Luzhong Refractory Co., Ltd., which was founded in 1970s. With a staff of more than 1000 including 88 engineering technicians and 10 external technic advisors in the level of professors, we have been keeping a long term research cooperation with universities and research institutes such as Beijing University of Technology, Liaoning University of Technology, Henan University and Shandong University of Technology, and have been verified as the “ Teaching and Research Practice Base” by Wuhan University of Technology, Shandong University of Technology and China Maritime University. Luzhong Refractory Group is a member of National Refractory Industry Association, State Building Materials Association and China Cement Association, the designated unit in thermal insulating refractories by the State Grid, provincially trustworthy and high technic, and one of the top 500 China building material enterprises verified by the China Building Material Industry Management Association.

We have successively passed the certifications of ISO9001 Quality Control System, ISO10012 Measurement Management System AAA, ISO18001 Vocational Health and Safety Management System and ISO14001 Environmental Management System, and were verified as “the AA Standard Good Conduct Enterprise” by the Shandong Provincial Bureau of Technic Supervision.

Guided by national economic development requirements and environmental protection policies, driven by scientific and technic innovation, aiming at energy conservation and consumption reduction, responsible for paying back society, we have developed a number of new green and environmental products with independent intellectual property by means of cooperation with universities and establishing research centres, gradually grown into a comprehensive refractory company integrating refractory research, raw material process, kiln refractory design, production, sales and service, with a capacity of 400,000 tons of various refractories, led and radiated technic progress and industrial development in relative industries, and realized great economic and social benefits.

Technic Advantages

We are the national new material industrializing base key enterprise and the advanced tech enterprise, with a strong developing ability.

In 2006, approved by Shandong Provincial Development and Reform Commission, in conjunction with Beijing University of Technology and Shandong University of Technology, we established the Shandong Provincial Refractory Project Research Centre, the only refractory research centre in Shandong, which was upgraded as the National and Local Refractory Joint Project Research Centre by the National Development and Reform Commission. With an investment of 60 million RMB and covering an area of 27.6 mu and a building area of 12,000m2, the centre has over 30 professors and associate professors (including senior engineers), over 50 medium and higher professional technicians, creative research ability, strong technic, advanced equipments and detecting instruments.

Since its inception, the centre has been focusing on the research and innovation of quality refractories and special ceramics, provided competitive environmental products, obtained 18 national patents including 11 invention patents, passed 4 provincial and ministerial scientific achievements authentications, obtained 1 second award of provincial scientific progress and 2 municipal scientific progress awards, drafted 8 industry standards, and completed nearly 100 items of new product developments, new technology and technic improvements. Meanwhile, the cooperation with universities has provided strong scientific supports for our progress.

Mating advantages

After many years of accumulation and development, Luzhong Refractory Group has formed her own mating and scale advantages, which are solid foundation for healthy and fast development of enterprise. We have 5 raw materials producing and processing bases in Shandong and Shanxi, where ores have good quality, large stock and stable supply. We can get various materials for production and ensure the stable and continual quality; meanwhile the raw material self-supply can decrease the producing cost and increase the competitive force.

Our products cover all refractories for cement kilns, ranging from castables, common refractory bricks to advanced magnesia hercynite bricks, ceramic inner cylinders in preheaters, and can provide one-stop service for cement producers. Based on the communication with cement producers and design institutes and the optimization of high-end refractories, we put forward a set of new technics of energy conservation and environmental protection for refractories in cement production, which can meet the requirements of national environmental protection policies and decrease the costs of cement producers.

The location of the group—Zibo has a large scale, intensive and comprehensive refractory industry in addition to a good machinofacture ability, broad downstream markets for cement, carbons and non-ferrous metals and convenient transportation and information exchange, which became the mating advantages for our development.

We render a whole range of excellent refractories, which include the following products: high intensity alkali-resistant bricks RK-H, silicon mullite bricks, anti-spalling alumina bricks KBL-70, magnesia alumina spinel bricks, low thermal-conductivity anti-spalling bricks DDR-30, DDR-45, low thermal-conductivity magnesia alumina spinel bricks DDRML-80, low thermal-conductivity alkali-resistant bricks DNJ-30, magnesia hercynite bricks, ceramic inner cylinders of preheaters, silicon mullite compound bricks, phosphate alumina compound bricks, phosphate alumina bricks, castables, energy-conserving harrows for castables, etc. We can also customize according to your needs.

- Main Product

Related Products

RYMAX Low Frequency Magnesium Sound Insulation Board | Sound

Eco-Friendly Finishing Coating Material

CPVC PIPE FITTING

High Alumina Bricks

FR Coating

China

China