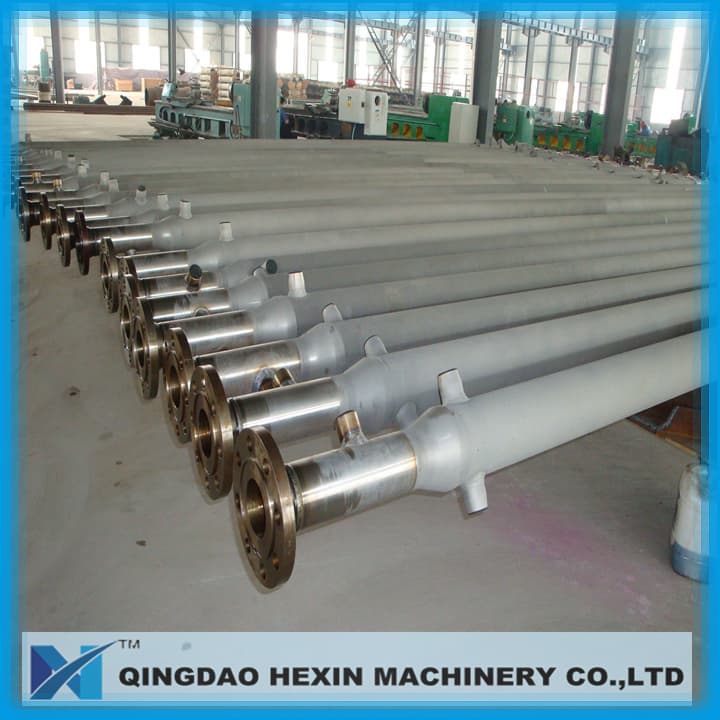

centrifugal casting reformer tube

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- heat resistance, spun cast, reformer tube, centrifugal cast

- Category

- Other Metal & Metallurgy Machinery

Qingdao Hexin Machinery Co., Ltd

- Verified Certificate

-

11

| Product name | centrifugal casting reformer tube | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | heat resistance , spun cast , reformer tube , centrifugal cast | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Specifications

heat resistant casting tubecentrifugal casting/spun casting

for Steam reformer

high nickle and high chrome alloy

Reformer tubes, Catalyst tubes,

Tubes assemblies for steam reformer and steam cracker, reformer /catalyst tubes, radiant coils, reformer harp coils, cracker tubes, ethylene cracking(pyrolysis) Coils, hairpins, hangers, outlet collectors, inlet and outlet manifolds, tube stanchions, convection coils, pigtails, tube sheets, tube supports, transfer lines, furnace hooks,T-pieces ,Y-pieces, flanges, pump, valve and other static castings.

Application:

Steam reformer and cracker, ammonia production, convection furnaces, Direct Reduction of Iron (DRI),ethylene pyrolysis, hydrogen production, Methanol production ,

Process:

Centrifugal casting, static casting, hole boring, welding .

Material:

High Nickel and high Chrome heat resistant alloys, Cobalt base alloys, like.

HU,HT,HK,HP,HW,24/24NbTiZr,50Cr/50Ni(2.4813),1.4865,1.4849,1.4848,1.4410,1.4059,1.4841, 1.4845,1.4852, 2.4879 or as per customer's requirements

Standard:

ANSI,ASTM,ASME,DIN,GB etc.

Quality control:

We have in-house facility for each inspection:

Chemical analysis by Spectrometer; Measurement inspection;

Mechanical properties testing, Pressure testing, Non destructive inspection (NDT): Ultrasonic, X-ray, PT , Eddy current testing.

Certificates:

ISO9001:2008;3.1B Material Certificates,SGS Certificate.

Advantages:

- More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice.

- Use ONLY new raw material like Nickel plate, Chrome iron,Cobalt,Ferrotungsten to guarantee physical property and Increased service Life of our castings.

- Owned In-house production and inspect facility to guarantee the best quality possible.

- Experienced workers for foundry,machining and welding guarantee excellent quality and prompt delivery.

- Focused sales and customer-service team are working with 100% passion to offer you a five-star purchase experience.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sales

- Product Category

- Glass Production Machinery,Metal & Metallurgy Machinery,Other Metal & Metallurgy Machinery

- Company introduction

-

Qingdao Hexin Machinery Co. ,Ltd. is a pioneer and leading manufacturer of centrifugal/spun casting and static casting with high nickel and high chromium alloys. The castings are widely used in refineries, fertilizers, petrochemical industry and metallurgical industry. Hexin TPE is an ISO9001:2008 qualified foundry with over 400 employees, which cover 52,000 square meters and is equipped with 200 sets of latest facilities. To continuously improve our quality and technology, we collaborated with The Chinese Academy of Sciences and built our R&D center for High performance furnace tubes. Thanks to our high quality and consistent QA/QC standard, we are awarded the top-quality-supplier by SINO-PEC, PETRO-CHINA, CNOOC and SINOCHEM, and we are also an innovative worldwide supplier with excellent quality and extensive experiences.

- Main Product

China

China

_2.jpg)