Vacuum insualtion panel production machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Heat Insulation Materials

Vacumn Insulation Tech CO.,LTD

- Verified Certificate

-

11

| Product name | Vacuum insualtion panel production machine | Certification | - |

|---|---|---|---|

| Category | Heat Insulation Materials | Ingredients | - |

| Keyword | thermal insulation , thermal insulation panel , vacuum insulation | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

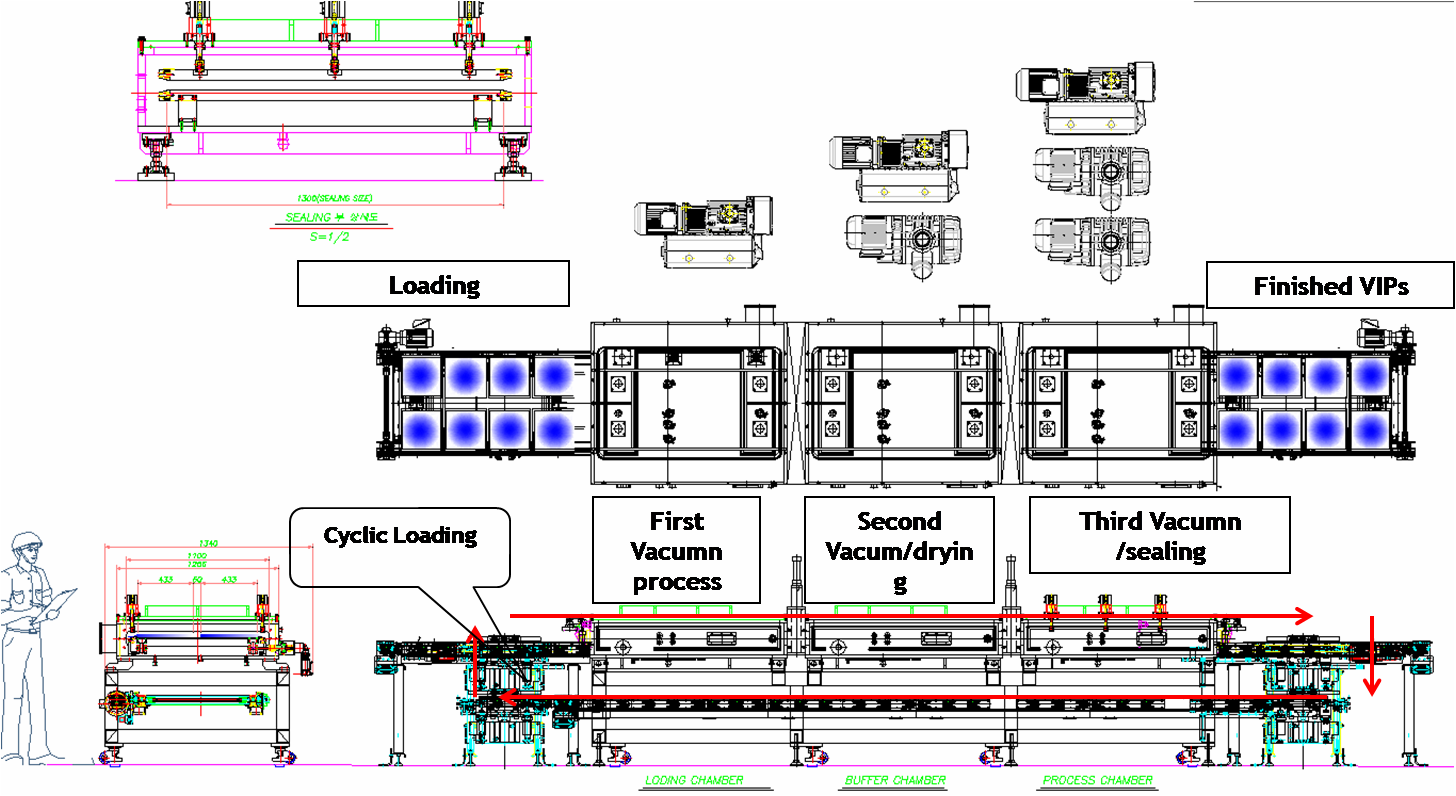

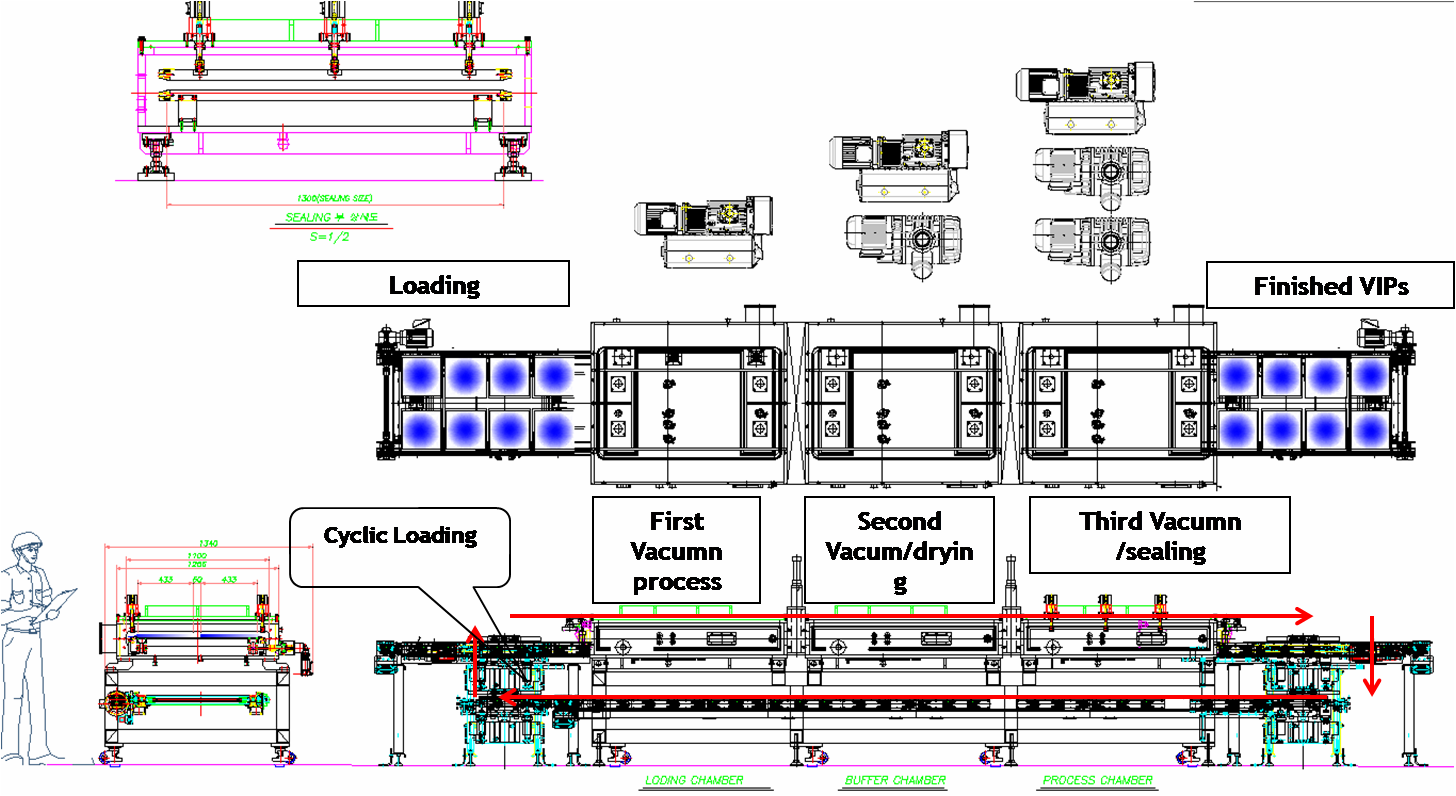

AUTOMATIC VACUUM PROCESS PRODUCTION LINES

The VIT is offering complete automatic production lines for a large range of vacuum processes and products. We have built such lines for several applications, such as automatic vacuum insulation panel (VIP) production,

Key features

- First demonstration system wil be issued on August and delivered to domestic VIP manufacturer,

- Automated Vacumn insulation panel production line concept for mass production

- Horizontal three chamber system performing vacumn, drying and sealing process for mass production

- Circulatory loading tray system

- Product size: Can be customized at customers’ request

- Working vacuum degree: 1.0*10-1pa, also can be increased more at customers’ request

- Suitable materials: silica powder, glass fibre

- Complete automatic performance except for manual loading and unloading workpieces.

- Complete mechanical and electrical locking and protection system, virtual man-machine interface and solo control software.

- Inflexible setup as needed of seal temperature and time, working vacuum degree and other parameters in the process

- Advanced non-oil design assuring a clean production surrounding and non-pollution of equipment.

- Crucial parts of imported brands with guarantee of famous Germany brand pump unit.

- Product size can be customized at customers’ request.

- Production Cycle time is 2 to 3 minutes.

- Thermal conductivity ≤0.003w/m.k (related to the materials), which can be as low as 0.0025 w/m.k if the material is of high performance

For more deatils , please contact with us.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sun Woo Park

- Address

- N201, Jooyoung BLD., 1030-8, Seo-Gu, Daegu, Korea

- Product Category

- Heat Insulation Materials

- Year Established

- 2013

- No. of Total Employees

- 1-50

- Company introduction

-

Vacumn Insulation Tech CO.,Ltd company team has developed, designed and manufactured vacuum processing and packaging machines since it's foundation in 2013. Custom-made vacuum packaging machinery for high performace thermal insulation panels.

Energy costs have risen dramatically in recent years, and vacuum insulation panels are a proven application that offers nearly ten times more energy-saving insulation than standard materials. Our equipment forms the basis to produce these VIP’s to the highest standards.

The VIT company is able to deliver all necessary equipment for VIP production.

We have expanded our original core business of vacuum chamber packaging machine system to VIP panel production having thermal conductivity below 0.0025 and life span of over 15 years.

Our products are marketed now only in domestic market under the registered brand name the VIT company.

- Main Markets

-

China

China

Japan

Japan

Viet Nam

Viet Nam

- Main Product

Related Products

PU PIR metal sandwich panel

WOODEN WOOD POLISHED PORCELAIN FLOOR TILE TILES 60x60

SH KOREA Heating Film SH310

SH KOREA Heating Film SH303

4R insulation cover

South Korea

South Korea