DELTABOT-K (3D Printer)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- 3d printer, 3d printing, equipment, machine

OTS Co.,Ltd.

- Verified Certificate

-

11

| Product name | DELTABOT-K (3D Printer) | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Printing Machines Other Machinery & Industry Equipment |

Ingredients | - |

| Keyword | 3d printer , 3d printing , equipment , machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

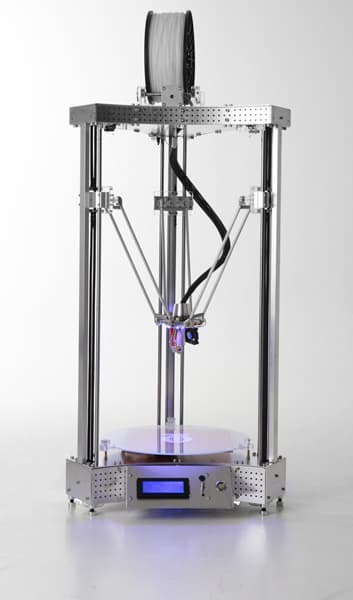

DELTABOT-K

│Basic specification│

|

KC certified |

MSIP-REM-GU1-DELTABOT-K |

|

Print type |

FDM (Fused Deposition Modeling) |

|

Mould maximum size |

200Øⅹ260 (mm) |

|

Filament (material) |

PLA / ABS |

|

ozzle diameter |

1.75/3.0mm (option) |

|

Lamination thickness |

0.2mm |

|

Power device |

240W (SMPS) |

|

Support O/S |

Windows/Mac/Linux |

|

Hot end temperature |

~260℃ |

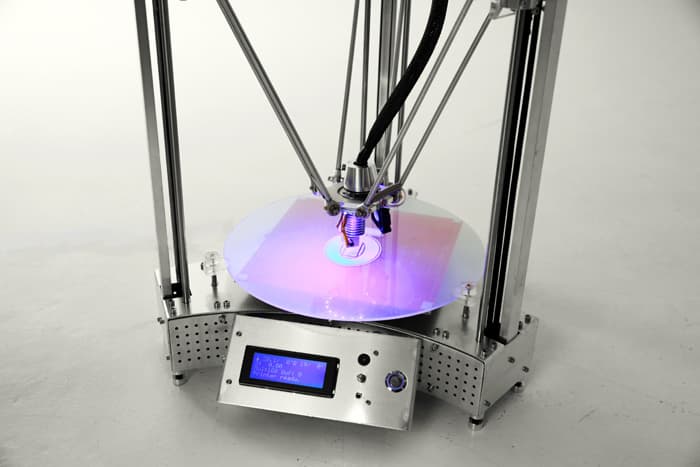

│Basic product components│

|

Aluminum case |

420ⅹ450ⅹ720 (mm) |

|

LED light |

Located at hot end bracket |

|

LCD panel |

Check operation and work conditions of the print |

|

Hot End |

Melt filament by raising temperature |

|

Filament holder |

Put filament on it to use |

|

Adaptor |

240W (SMPS) |

|

Extruder |

Push filament to insert |

|

Printing board |

Board where filament is laminated |

|

Nozzle (commodity) |

The far bottom part of hot end where filament comes out |

│Product features│

| 1) Ambient LED LIGHT which gives an interior effect. | 2) FULL METAL HOT END which can be used for a long period even at high temperatures | 3) LED PANEL with SD card which can be used without a computer connection. |

| 4) A FILAMENT HOLDER which can release filament with a soft rolling, and an EXTRUDER HOLDER for convenient use of the extruder. | |

| 5)KC MARK which adds trust in the product. | |

│Output Structure Image│

│Mendel/Delta Types Comparison│

|

|

Mendel type |

Delta type |

|

Driving type |

A driving type with such condition that Z axis is fixed on the floor and vertical X and Y axes move up and down. |

It is a driving type such that X, Y, and Z axes are connected with one head. |

|

Zero point |

Set a horizontal balance by moving a bed plate and a head together. |

Set a horizontal balance by using a nut of fixed bed after adjusting the height under the condition with which the bed plate is fixed. |

|

Speed |

Compared to the Delta type, there are relatively many restrictions in the horizontal and vertical movements of X, Y, and Z axes. |

Compared to the Mendel type, there is relatively little restriction as it uses one head. |

|

Completion |

When the work is done under the same condition, there is a higher failure rate because the bed is moving. |

When the work is done under the same condition, it has a higher completion rate compared to the Mendel type as the bed is not moving. |

│Merits of Delta Type│

- High speed :

As the X, Y, and Z axes are connected to one head, it is relatively possible to work with high speed compared to the Mendel type which has many restrictions. - High completion rate :

As the bed is not moving, it is possible to work continuously in the middle of the laminating process even though a contraction or a deformation occurs. It can not only lower the failure rate but also increase the completion rate for the long hours of work. - Flexible expandibility :

With free movement of head, it is easy to expand it from a small size to a giant size. For the Deltabot-K giant size, it is possible to work up to the size which can mould in the high price equipment. It is possible to modify it into a diverse machine by combining other equipments to the head.

│Comparison with Other Company's Products│

|

Extruder |

|

|

Other Company's Product |

Our Company's Product |

|

The strength to pull it to the acrylic extruder is weak, and it has high abrasion. |

Full metal has a strong and constant strength to pull it to the extruder so that it has a merit to increase the completion rate; and it is possible to use it for a long hours compared to the acrylic material. |

|

Hot End |

|

|

Other Company's Product |

Our Company's Product |

|

As it is a peek material (similar to plastic), it has a lower heat temperature to resist compared to the metal. |

As it is a full metal material, it has a fast heat transfer rate and it is easy to adjust the temperature with a pen. As it resists the high heat, it can be used for other materials besides the plastic. |

│Competitiveness of DELTABOT-K│

|

Full metal hot end |

It can raise the heat or lower the heat, and also it is possible to adjust the constant temperature with a pen.It is possible to use diverse filaments from the plastic material to the metal material which has a strong heat resistance. |

|

LCD panel |

It is possible to print by using an SC card which has a file with a G-code partition without a computer connection. |

|

LED light |

It can give an interior effect to the head through the light. |

|

Adaptor type |

In order to reduce the cost of the 3D printer which requires a long output hour, it is possible to reduce the power consumption by using a low power adaptor. |

|

High completion rate |

As the bed does not move, it has a high completion rate of the output structure. |

|

High speed |

As it has the same speed as that of the Mendel type, it has a high success rate during the work. |

|

Extruder |

It has a good strength to hold and push the filament by increasing the torque, and it is convenient to insert the filament to use. |

|

KC certified |

I has acquired the KC Certified Mark which is the integrated national certification mark so that it is safer to use. |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- yoosoon Park

- Address

- (411-809) OTS 3D Center, 937-24, Deogi-dong, Ilsanseo-gu, Goyang-si, Gyeonggi-do, Korea

- Product Category

- Printers & Scanners

- No. of Total Employees

- 1-50

- Company introduction

-

We manufacture and distribute 3D printers. We have put a lot of effort into the 3D printer and are accumulating a lot of technology. Through R&D, we are striving for the development of not only FDM 3D printers, but also SLA, DLP, and SLS. We are not a big company but we think of research and development of high quality instruments as our pleasure and we are devoting our passion on the business. We will keep up our hard work for - Vision2016. Wiewing Delta System 3D Printer, Asia No.1 & Customer Satisfaction Index No.1

- Main Markets

-

Australia

Australia

Ghana

Ghana

India

India

South Africa

South Africa

South Korea

South Korea

- Main Product

Related Products

Torrington Bearing

Flange

FAG NTN NSK KBC bearings

UIM2901-5A MACH3 break out board for CNC

Airless Pump (Ratio 63:1 Airless Pump)