MOTOR BASE

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- lautec Co.,Ltd

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Machinery & Parts , General Industrial Equipment

lautec Co.,Ltd

- Verified Certificate

-

12

| Product name | MOTOR BASE | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

General Industrial Equipment |

Ingredients | - |

| Keyword | auto aliging system , belt cleaner , motorbase , water cleaning system | Unit Size | - |

| Brand name | lautec Co.,Ltd | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

MOTOR BASE

The surface of the conveyor belt for the removal of foreign matters adhering to the belt cleaner device. Belt cleaners are used for cleaning conveyor belts commonly used in various work sites such as steel mills, thermal power plants, cement plants, and mines that transport different substances like raw materials and fuel. A large amount of these floating substances do not only attach onto the surface of conveyor belts that transport various raw materials, but also onto the snap pulleys and return rollers.

│Description│

- Keeps proper tension on belt when belt stretches out.

- Absorbs belt shaking in a second by swiveling so that overload can be placed on belt at initial operation.

- Prevents slip.

- Extends life of belt remarkably.

- Self-damping function absorbs vibration of motor and shaking of belt in relaxed side.

- Changing belt is simple.

│Operation of belt│

In case of V-belt, proper tension should be given to belt to transfer required torque to machine and facility effectively. Belt is stretched out by overload placed on belt when facility operates and, if no tension is given to belt at this time, belt slips, jumps and shakes. Furthermore, noise by friction sounds and worn out of pulley becomes significant.

│Summary of MOTORBASE│

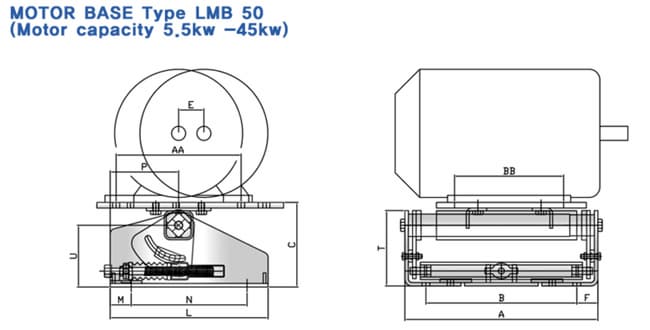

- LMB-27: Use for electric motor (0.75Kw – 4Kw)

- LMB-50: Use for electric motor (5.5Kw – 45Kw)

- LMB-70: Use for electric motor (37Kw – 120Kw)

- 5 kinds of Rubber Suspension Units are available depending on motor capacity.

- Complete product of motor base is available but user also can make motor base by purchasing necessary kits only

- Most customers purchase Rubber Suspension.

- Unit and Pretensioning Devices only and make brackets by cutting and bending according to the drawing and dimensions in product catalogue.

- There are three grooves in Pretensioning Device and the grooves are for quick adjustment of plate angle.

- Set proper tension of belt based on belt type and number of strands of belt.

- LMB-27 is so compact that it can be installed in any place and also can be installed in the same place where old motor base was installed.

- Pretensioning Device can be installed on either left side or right side depending on the position of counter pulley.

│Summary of MOTORBASE│

Three functions of Motor Base

- Tension

- Damping

- Making belt change easy

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Seo Suk Ho

- Address

- 29-112 Gwangju Industrial Circulation Center, 948 Maewall-dong, Seo-gu, Gwangju, Korea

- Product Category

- General Industrial Equipment,Machinery & Parts

- No. of Total Employees

- 1-50

- Company introduction

-

Lautec is a company that puts others first, manufactures its products based on its philosophy that any products produced, are what we use for ourselves. Lautec was established in 1995 and strives to improve product quality and to develop excellent new products based on its accumulated technologies and experience for belt conveyor peripherals and factory automation systems.

Belt cleaners are used for cleaning conveyor belts commonly used in various work sites such as steel

mills, thermal power plants, cement plants, and mines that transport different substances like raw materials and fuel. A large amount of these floating substances do not only attach onto the surface of conveyor belts that transport various raw materials, but also onto the snap pulleys and return rollers.

As a result, the diameter of the pulleys increases unevenly, causing the belts to roll and bend. In worst cases, it would be impossible to operate the machine. The mechanism would also become excessively dirty. When the surface of the belts is cleaned, the effect is very positive as explained below.

Based on this it has resulted in many patents and utility models, and they are widely utilized as products that prove their merits on actual sites of various companies with favorable response.

Lautec does not settle for its current accomplishment, it makes even more endeavors to be an enterprise that can contribute to the development of the country and society based on its corporate spirit as a company that puts others first, benefits its customers, and pioneers its future by constantly researching attitudes and investments.

As a company that prepares for the future, Lautec strives to become a company that makes further efforts in its research to produce world-class products that can compete in the competitive world market, and the one that approaches customers with the best quality and perfect services.

In this regard, we would appreciate your cooperation and attention. Thank you.

- Main Product

Related Products

Modbus Device Recorder

UIM2901-5A MACH3 break out board for CNC

_2.jpg)

Cable and Wire harness tester (MHT-610 / 705)

Airless Pump (Ratio 63:1 Airless Pump)

_2.jpg)

Turbowin Turbo Blower (WL Series)

South Korea

South Korea

![cbe9caa5_a8c10f5b_f245_44e8_a5cf_21fd37e449f4 BELT CLEANER - [CP-L]](https://web.tradekorea.com/product/426/375426_02/cbe9caa5_a8c10f5b_f245_44e8_a5cf_21fd37e449f4.jpg)

![cbe9caa5_a744960f_9baf_4fe9_96a3_97e6bef65187 BELT CLEANER - [Urethane Cleaner]](https://web.tradekorea.com/product/420/375420_02/cbe9caa5_a744960f_9baf_4fe9_96a3_97e6bef65187.jpg)