Shiplift and ship transfer system

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

MTI Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | Shiplift and ship transfer system | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | ship transfer system , shiplift , shiplift and ship transfer system | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Shiplift and ship transfer system

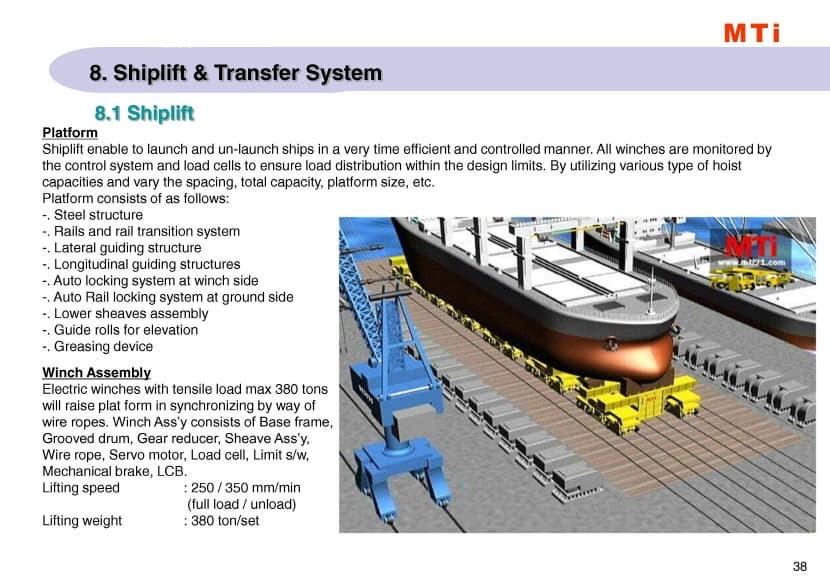

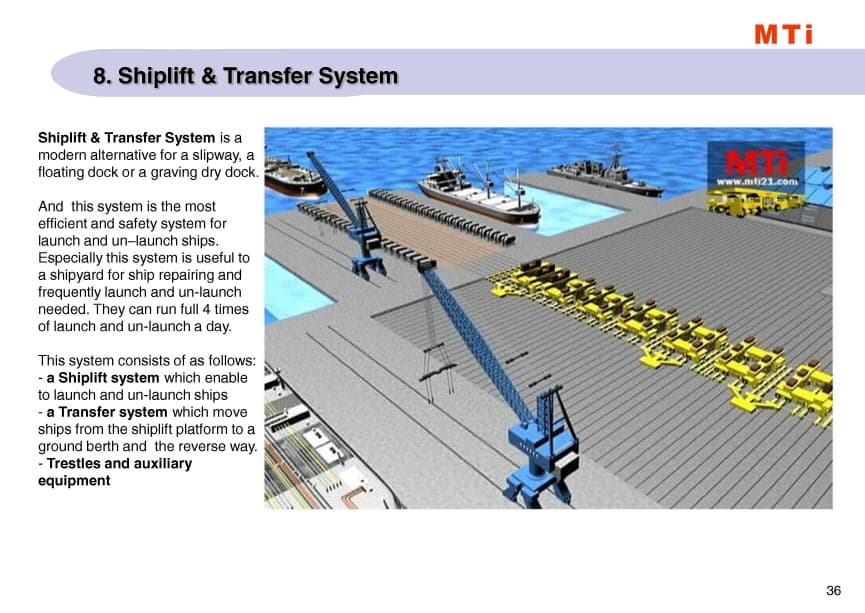

MTi produce and supply all kinds of shipbuilding equipments, specially MTI Shiplift and Transfer system is famous for efficiency and safety in shipbuilding work.

For more detail information, pls visit our web site; w w w . mti21 . c o m and if you have any question, don’t hesitate to contact us; jaewoo707 at g m a I l . c o m and the characteristics are as below;

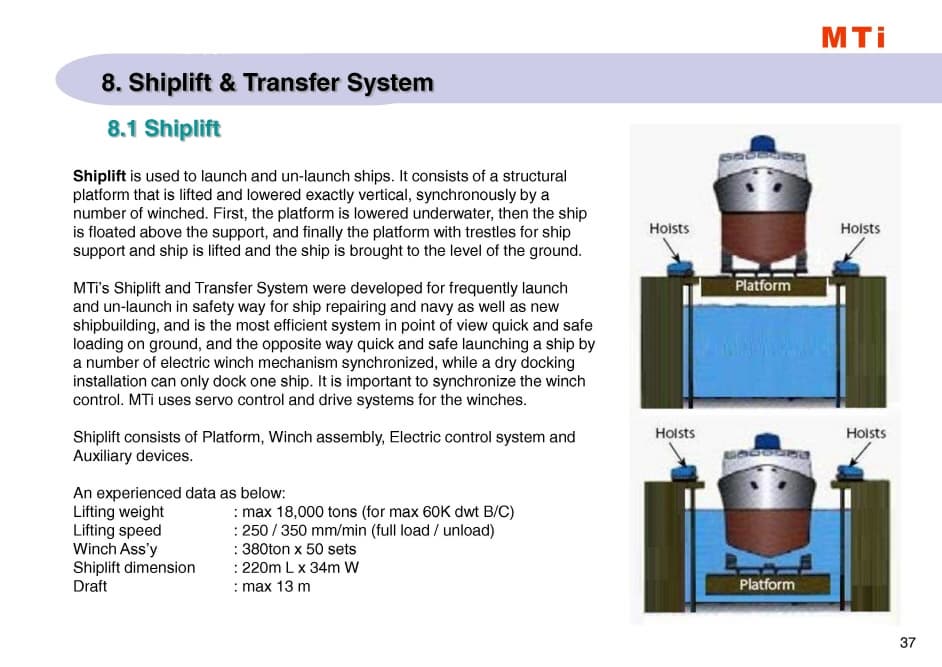

Shiplift

A shiplift enable your yard to launch end retrieve ships in a very time efficient and controlled manner. All winches are monitored by the control system and load cells to ensure load distribution within the design limits. By utilizing various type of hoist capacities and vary the spacing, total capacity, platform size, etc.

Lifting capacity: 18,000 tons

Lifting speed: 550 mm/min

Shiplift dimension: 120m L x 34m W

Draft: 11 m

MTi’s Shiplift uses a Transfer System for ships so that the vessels can be transported from the water to a ground berth where they can be painted or repaired. One shiplift can serve many parking places, while a dry docking installation can only dock one ship. It is important to synchronize the winches. MTi uses electrical control and drive systems for the winches.

Transfer system

MTi’s ship Transfer System is designed to transport ships between a shiplift or Floating dock and dry berth on land. The transfer system is a robust, easy-to-operate system that requires little maintenance. It can be submerged and stored outdoors without damage or adverse effects. The Rail Transfer System runs on rails and can move both in lateral and/or transverse directions. The transfer system will move the vessel on a fluid bed with full control over the forces to the hull and the wheel loads. The system consists of a number of transfer trolleys, each with lifting capacity up to 500 tons.

There’re 2 kinds of transfer system as below;

1. Transfer system with Intermediate Traverser: Model : TIT type

TIT system consists of a number of Transfers and an Intermediate Traverser

Transfer has function of self-run by diesel engine and up and down by hydraulic, and a control system with wireless communication to control a series of Transfer synchronously.

Intermediate Traverser has function of self-run by electric motor and chain push and pulling mechanism

In this system, Transfers run longitudinal and Traversers run cross way only.

2. Transfer system with 90 degree Turning Bogie: Model : TTB type

TTB system consists of a number of Transfers which run longitudinal and cross way by way of diesel engine, up and down by hydraulic. The bogie of Transfer can turn to 90 degree in order to change moving direction.

Basic technical specification of two type transfer is as below;

Static payload: 500 tons

Axle load: 8 nos x 62.5 tons

Engine: HMC D4BB / 75Hp

Transfer speed: 5 / 8 m/min (load / no load)

Control system

This control system can continuously monitor and display loadings, speed, turning direction and positioning of each transfer, and run synchronized all together under normal condition of all transfer, if a transfer run abnormal condition on loadings, speed, turning direction and positioning, the transfer will try to fit with other by itself, but when the result is out of allowable range, all transfer system will stop and warn emergency.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sang Jun , Shin

- Address

- 1189, Namun-dong, Jinhae-gu, Changwon-si, Gyeongnam,Korea

- Product Category

- Chemical Storage Equipment,Machinery & Parts,Other Machinery & Industry Equipment

- Company introduction

-

MTi was founded in Gimhae city, Gyeongsangnam-do, Korea in 1983, is one of leading company for engineering and supplying Steel making equipment and Coil processing line in the world today, and started to make a business for Shipbuilding equipment and Cranes from 1993. Our goal is to provide advanced, efficient, qualified equipment with the lowest cost to our worldwide customers. Main business is; 1. Engineering and supplying of Steel making equipment and Coil processing line - Hot rolling mill : Plate rolling mill, Thick plate mill, Pipe & tube mill, Section & structural mill, Rod & bar mill - Cold rolling mill : 2, 4, 6- High rolling mill, 20-High Sendzimir mill, Skin pass mill - Coil processing line : Cut to length line, Slitting line, Recoiling & Tension leveling line CCL, CGL, EGL, PPL, POL, Blanking line, Plate & Coil Packing line, Steel strap band line, Degreasing line, Roll forming line - Revamping with Automatic control system 2. Engineering and supplying of Shipbuilding equipment - De-scaling line - Cutting shop equipment : CNC Gas Cutting M/C, CNC Plasma Cutting M/C, CNC Beveling M/C, CNC Drilling M/C, CNC Pipe Cutting M/C - Bending shop equipment : CNC Hydraulic Roll Press, CNC Hydraulic Press Brake, Hydraulic Portal Press, Hydraulic C- Frame Press, Hydraulic Frame Bender, Hydraulic Vertical Bender, CNC Horizontal Roll Bender - Pipe shop equipment : CNC Pipe Cutting M/C, CNC Pipe Bending M/C, Pipe Coaster, Band Saw M/C, Positioner, Turning roll (Rotator), Welding Manipulator - Hull shop equipment : Built-up line, Automatic Welding gantry, Panel and Block Fabrication Line, Curved Block Fabrication Line, Welder and welding equipment - Shot blast and Painting shop equipment - Shiplift & Load-out system - Floating Dock & Launching System - Ship Design and Shipyard Consulting 3. EPC Plant - Power & Energy Plant - Oil & Gas - Pressure Vessel, Reactor - Cryogenic Plant - Desalination Plant - Wind Power - Special Plant & Facilities - Modules & Offshore plant 4. Engineering and supplying of Cranes and Transportation equipment - EOTC, Gantry crane, Goliath crane, Tower crane - RMQC, BTC, RTGC, LLC - CSU (Continuous Ship Unloader), Stacker and Reclaimer 5. Used equipment : Used pipe mill line, Used rolling mill, Used cut to length line, Used Slitting line, Used cranes, MTi has various, valuable and cheap 2nd hand equipment for above mentioned equipment and we operate big association with worldwide suppliers for 2nd hand equipment supplying, so you can be satisfied with our service when you contact us. 6. Parts supplying : - Automobile parts :Forging parts for Transmission, Door and hinge, Steering, Hub and spindle: Rear axle, Pitman arm, Spider, Tie rod, CV joint, Knuckle, Shaft, Yoke, Pinion gear, TM gear, Cam shaft, Con’ rod, Crank shaft, Hub, Clutch sleeve, Molding parts Brake Ass’y, Engine control parts - Marine parts : - Standard purchasing parts : Hydraulic cylinder and solenoid valve, Pneumatic cylinder and solenoid valve, Bearing, Sensor, Switch, Pipe fittings, AC/DC - MIG and TIG welder, Frame cutter

- Main Markets

-

Bangladesh

Bangladesh

Iraq

Iraq

Kuwait

Kuwait

Malaysia

Malaysia

Saudi Arabia

Saudi Arabia

Viet Nam

Viet Nam

- Main Product

Related Products

New High Pressure Exhaust Fan(30cm)

Audio Grade PCIe Host Card – tX-USBexp

AIS3000 HD

3INCH POS RECEIPT PRINTER, Thermal Receipt Printer 80mm.

AIRLESS PUMP- YL 731