Vertical Agitator

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Kisan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- agitator

- Category

- Industrial Supplies

KISAN MACHINERY INC.

- Verified Certificate

-

11

| Product name | Vertical Agitator | Certification | - |

|---|---|---|---|

| Category | Industrial Supplies | Ingredients | - |

| Keyword | agitator | Unit Size | - |

| Brand name | Kisan | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Vertical Agitator

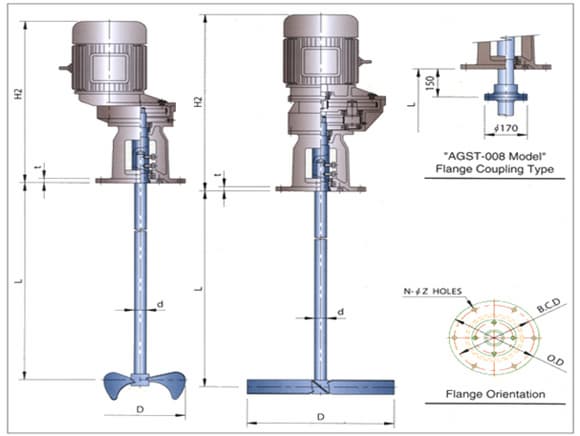

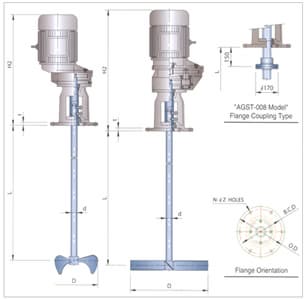

l AGST - Standard Agitator / Flange Type l

The mass production of standardized parts, complete systems affordable and to ensure prompt delivery.

Coupling method is the Flange (Bolt mounting) has become the installation to easy.

Gear make to use MC Nylon and polishing. So the noise is small.

Depending on the application to be rotating of the agitator can be selected.

Mass production of standardized parts, complete systems affordable and to ensure prompt delivery.

l Dimension Tab l

|

Model NO. |

Moter Power |

RPM |

Mixing Shaft |

Impeller |

H1 |

H2 |

OD |

BCD |

N-Z |

t |

Weight (kg) |

||

|

kW |

HP |

d |

L(max) |

D |

|||||||||

|

AGST-002 |

0.18 |

1 / 4 |

350 |

20 |

800 |

120-500 |

345 |

370 |

140 |

120 |

4-10 |

10 |

23 |

|

300 |

|||||||||||||

|

AGST-005 |

0.4 |

1 / 2 |

240 |

20 |

1400 |

200-700 |

430 |

465 |

170 |

150 |

4-12 |

12 |

30 |

|

AGST-01 |

0.75 |

1 |

180 |

25 |

1700 |

250-800 |

465 |

500 |

200 |

170 |

4-12 |

14 |

35 |

|

AGST-02 |

1.5 |

2 |

120 |

30 |

2200 |

300-1000 |

615 |

660 |

230 |

200 |

6-12 |

17 |

55 |

|

AGST-03 |

2.2 |

3 |

90 |

30 |

2500 |

350-1100 |

660 |

720 |

260 |

220 |

6-13 |

17 |

70 |

|

AGST-05 |

3.75 |

5 |

60 |

35/40 |

2800 |

400-1200 |

650 |

710 |

300 |

260 |

6-18 |

22 |

90 |

|

AGST-08 |

5.5 |

7.5 |

-40 |

40/50 |

3200 |

450-1500 |

740 |

800 |

345 |

305 |

6-23 |

25 |

120 |

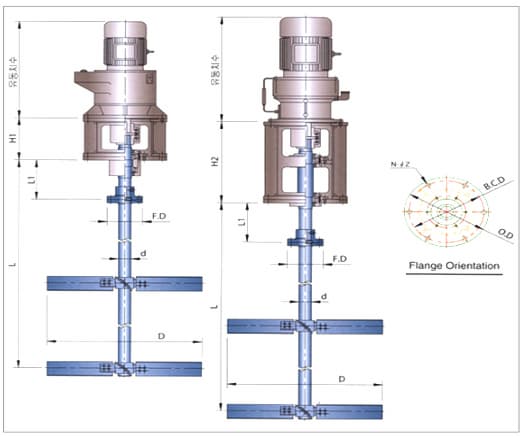

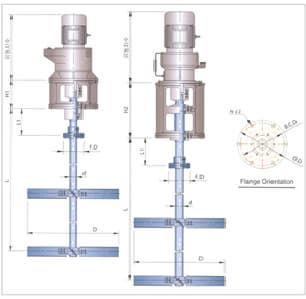

l AGGT - Large Agitator/Medium-Low Speed Type l

Manner as made to order the production in response to various agitation conditions is possible.

Reducer is Gear / Cyclo / Worm such as variety of formats to choose from, Transmission Gear Box can also be converted to the speed of the mounting.

Mounting Flange standard of JIS (10kg / ㎠) Code is compatible with the enhanced standardization.

Under the terms of the agitated tank inside the Mechanical Sea / Gland Packing / Water Seal / Cap Seal Sealing System to see the variety can be mounted.

Heavy-duty design of the high viscosity of large large tank / agitation tank / storage tank as a suitable stirring device.

l AGGT - Large Agitator/Medium-Low Speed Type l

|

Ratio |

5 : 1 |

7.5 : 1 |

10 : 1 |

15 : 1 |

20 : 1 |

30 : 1 |

45 : 1 |

60 : 1 |

90 : 1 |

|

Reducer Type |

6 : 1 |

8 : 1 |

11 : 1 |

15 : 1 |

21 : 1 |

29 : 1 |

43 : 1 |

59 : 1 |

87 : 1 |

|

Gear REducer |

360 |

240 |

180 |

120 |

90 |

60 |

40 |

30 |

20 |

|

Cyclo Reducer |

300 |

225 |

164 |

120 |

86 |

62 |

42 |

31 |

21 |

l Dimension Table l

|

Model NO. |

Moter Power |

Mixing Shaft |

Impeller |

H1 |

H2 |

H3 |

FD |

OD |

BCD |

N-Z |

|||

|

kW |

HP |

d |

L(max) |

L1 |

D |

||||||||

|

AGGM-D030 |

0.4~2.2 |

1/2~3 |

30 |

~1200 |

200 |

200~500 |

240 |

505 |

730 |

100 |

330 |

290 |

6-23 |

|

AGGM-D040 |

40 |

~1500 |

200 |

250~700 |

240 |

505 |

730 |

125 |

330 |

290 |

6-23 |

||

|

AGGM-D050 |

50 |

~2000 |

200 |

300~1000 |

240 |

505 |

730 |

145 |

330 |

290 |

6-23 |

||

|

AGGM-D060 |

0.75~5.5 |

1~7.5 |

60 |

~2500 |

250 |

350~1200 |

260 |

545 |

785 |

170 |

400 |

355 |

6-25 |

|

AGGM-D070 |

1.5~11 |

3~15 |

70 |

~3200 |

300 |

350~1500 |

300 |

645 |

925 |

200 |

445 |

400 |

8-25 |

|

AGGM-D080 |

80 |

~3500 |

300 |

350~1800 |

300 |

645 |

925 |

220 |

445 |

400 |

8-25 |

||

|

AGGM-D090 |

3.75~15 |

5~20 |

90 |

~3800 |

350 |

400~2200 |

347 |

752 |

1077 |

260 |

490 |

445 |

8-25 |

|

AGGM-D100 |

7.5~22 |

10~30 |

100 |

~4000 |

400 |

450~2500 |

405 |

825 |

1205 |

300 |

560 |

510 |

12-27 |

|

AGGM-D110 |

110 |

~4200 |

400 |

450~2500 |

405 |

825 |

1205 |

330 |

560 |

510 |

12-27 |

||

|

AGGM-D120 |

7.5~45 |

10~60 |

120 |

~4500 |

450 |

500~2800 |

455 |

930 |

1360 |

345 |

620 |

565 |

16-27 |

|

AGGM-D130 |

130 |

~4500 |

450 |

500~3000 |

455 |

930 |

1360 |

355 |

620 |

565 |

16-27 |

||

Frame by Motor Power is subject to change.

Impeller Dia. "D" dimensions are changes may

Mixing Shaft of the "L" dimensions Stabilizer FIN (RING) and Foot Bearing will be adjusted upward depending on whether or not the mounting. Support Frame of "H2/H3" reducer type and dimensions of Mechanical Seal, there may be some differences.

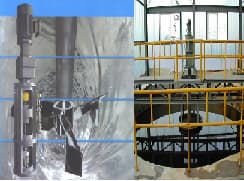

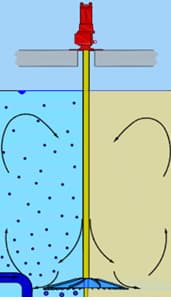

l KDM– DISK Type l

Production method of an order corresponding to the production conditions of the reaction tank is possible.

Gear reducer low speed operation of the reactor and the agitator is suitable.

Installation location of the impeller installed in the bottom of the tank bottom to minimize sediment flow rate can be increased.

l Applications l

l Dimension Table l

|

Model NO. |

impeller |

kW |

RPM |

shaft diameter |

Capacity (m3) |

Shaft length |

|

KDM-005-1000 |

1000 |

0.37 |

~ 45 |

65A |

~100 |

Customized on-site |

|

KDM-005-1500 |

1500 |

0.37 |

~ 24 |

80A |

~100 |

|

|

KDM-010-1500 |

1500 |

0.75 |

~ 30 |

80A |

~200 |

|

|

KDM-020-1500 |

1500 |

1.5 |

~ 35 |

80A |

~300 |

|

|

KDM-020-2000 |

2000 |

1.5 |

~ 24 |

100A |

~500 |

|

|

KDM-030-2000 |

2000 |

2.2 |

~ 28 |

100A |

~400 |

|

|

KDM-050-2000 |

2000 |

3.7 |

~ 32 |

100A |

~300 |

|

|

KDM-030-2300 |

2300 |

2.2 |

~ 22 |

100A |

~500 |

|

|

KDM-050-2300 |

2300 |

3.7 |

~ 25 |

100A |

~600 |

|

|

KDM-075-2300 |

2300 |

5.5 |

~ 30 |

100A |

~700 |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Ko, Il Young

- Address

- 15, World cup-ro 30-gil, Mapo-gu, Seoul, Korea

- Product Category

- Industrial Supplies,Water Treatment

- No. of Total Employees

- 1-50

- Company introduction

-

We are pleased to welcome you at Kisan. The following pages will provide you an over- view of our products and services.

Founded in March 1996 in the field of the water entering the water for a long time to produce the product as sold by the company based on its experience and world markets are.

- Our core competence is providing aeration solutions for biological wastewater treatment.

- Our success is based on continuous product innovation, friendly, competent service and zero-defect philosophy.

- Our customers are design engineers, OEM accounts, con- tractors and design-build companies all over the world.

- Main Markets

-

South Korea

South Korea

- Factory Information

-

kisan

- Main Product

_2.jpg)