Refrigement Leak Detector

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industrial Supplies , Testing Equipment

TAESHIN Co.,Ltd.

- Verified Certificate

-

11

| Product name | Refrigement Leak Detector | Certification | - |

|---|---|---|---|

| Category |

Industrial Supplies

Testing Equipment |

Ingredients | - |

| Keyword | testing equipment , refrigement leak detector | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Refrigement Leak Detector

│Specifications│

|

operating temperature range |

-20C~50C |

|

Minimum sensitivity to R-22,R-134a,R-404a |

0.1oz/year(3gm/year) |

|

size |

175mm X 75mm X 45mm |

|

Probe length |

430mm |

|

Pump suction capacity |

1800ml/min |

|

Response rate |

2sec |

|

Weight |

500gr |

│Features│

- The detector has the same sensitivity as R-22, R-134a, R-404a, R-410a, R-507(AZ-50), CFS, HCFC and HFC. So you don't have to reset or switch on the equipment by each refrigerant and it's more useful to use this detector, especially, when you don't know which refrigerant is used.

- The alarm gets louder when getting closer to leaking spots and the sound gets smaller when it gets far from the spots. You can detect the spots quickly and accurately.

- The detector is designed to show sensitively how much refrigerant is leaking through the two indicators, H(high) and L(low).

- The high efficient pump(1.8 litter/min) restores quickly to its normal condition when it gets out of the leaking spot and it keeps the air flowing through the sensor so as to react with refrigerants around it.

- The detector has a specially designed flexible probe in order to reach some difficult spots easily or some sports with obstacles.

│How to operate│

- It's easy to operate the AG-3000. Switch on the "Power" button and the machine turns on.

Then, it warms up for 16 seconds in total; the initial "blue" screen for 6 seconds and its own calibration from CA-10 to CA-0 for 10 seconds. After these, you can hear the dial tone for getting ready. - To detect the leak, begin detecting by placing the AG-3000's probe to the spot where the gas may leak with 5-6mm apart.

- Try to find out the exact leaking spot by moving the probe slowly(about 3-4cm per second).

- When the AG-3000 detects the spot, you can see the amount of detected leaking through ascending colors of green, sky blue, yellow, orange and red in the LED window of the probe. You can also hear the loud buzzer sound.

- Then, you can make sure the spot is leaking for sure by placing the probe to a different spot and bringing it back to the previous spot.

- When you try the spot with lots of debris many times or you don't think the sensitivity is strong enough, you can reset the machine by doing the ZERO calibration.

(How to calibrate: Turn on the equipment and press the "ENT" button in the bottom after the warming-up for 16 seconds. Then, press ↑ key and you can see "OCAL". Press the "ENT" key again and the detector begins to press the remaining pollutant gas inside the machine for 30 seconds.

If you still feel the detection is weak, you can open the probe cap in front and check contamination level of the filter cartridge inside the cap. You may exchange the filter with a new one by the contamination level. - When the detector isn't used for a while, it goes into the "stand-by" mode, which reduces the electricity consumption, in 10 minutes. When the "Stand-by" mode continues for 30 minutes, it automatically turns off.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Yoon, Tae Hoon

- Address

- #34-11, Ha-An 2 Dong(Samho bldg 605), Kwang-Myeong-Si, Kyeong-Gi-Do, Korea

- Product Category

- Industrial Supplies,Machinery & Parts

- No. of Total Employees

- 1-50

- Company introduction

-

We,TAESHIN,really appreciate you having supported and encouraged us since TAESHIN became the best company in the maintenance equipment area. AS a result,our effort to maintain a continuous development under a strong will aiiow us to be one of the best company in maintenance equipment in the whole world. We developed & produced the first wheel alignment system in our nation in 1991. We also developed the wheel balancer,tire changer,exhaust gas analyzer,diesel smoke tester,tire inflator as well. We grew up as an entire brand in car maintenance equipment area. TAESHIN`s reputation has been rapidly growing in domestic as well as the overseas market. We will dedicate ourselves to becoming the world`s best company in car maintenance equipment area with the brand name ``TAESHIN``, approved by our clients by establisshing a much stricter quality system. Keep your eye on TAESHIN`s future. Sincerely President TAE-HOON,YUN

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

Solar roof shingles / Solar tile / PV tile / Solar roof tiles

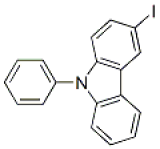

3-Iodo-N-phenylcarbazole, CAS NO.: 502161-03-7

_2.jpg)

ALUMINIUM PLATE/SHEET/COIL/EXTRUSION (ARCONIC/FUSINA)

DETDA(Diethyl toluene diamine) Polyurea curing agent

Micro Slack Wax WX-160S, Microcrystalline Wax