KumKang Machinery Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | FRP Pump (Vertical Non-Seal Pump) | Certification | - |

|---|---|---|---|

| Category | Pumps | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Material

Highly durable style of heat resistance and anti-abrasion FRP

* Independent molding on entire parts and custom-made manufacturing with special specification

Usage

- For transporting various chemical products

- For waste water treatment facilities

- For scrubber circulation

- For washing acid and alkali

- For circulation of coating liquid, filtering and etching

- For marine farming business

- For other industrial uses

Features

- Excellence of Material and Capability

- The material is in FRP with outstanding anti-corrosion, anti-thermal and anti-abrasion that it is widely used for various chemical uses. This is assembled with the optimal design and molding in precision casting part that the efficiency of the pump is very high with the perfect compatibility. - Possibility of running on empty

- With the empty rogation of the pump that has the mechanical seal built-in, the possibility of defect is completely excluded. - Easy to install for its light weight

- The weight is light with the dimensional type that it is easy to install in a narrow space. - Non Seal, No Packing, No Bearing

- The mechanical seal with the most trouble of the pump is removed that it contributes greatly for the productivity improvement. - Zero maintenance and repair cost

- The exchange of mechanical seal, packing and bearing is unnecessary that it contributes greatly for the productivity improvement without any waste on maintenance cost and human resource. - When Shutting Off (Completely lock the discharge valve)

- The liquid leakage is absolutely not made with the overflow. - Connection is made with a coupling for motor and pump axis that the motor bearing can be replaced without disintegrating the pipelines.

* Accurate capability test is done by the KS B 6302 pump discharge volume measurement.

Specification

- Flux : ~ 300 m3/hr

- Air lift : ~ 35m

- Diameter : ~ Ø200

- Temperature used : ~110°C

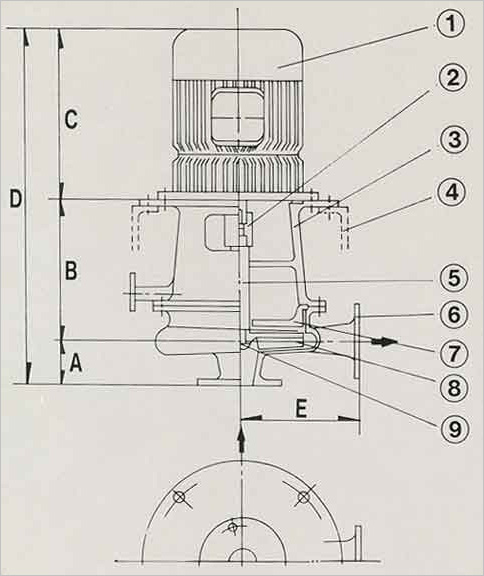

|

NO |

NAME OF PARTS |

Q'TY |

MATERIAL |

|

1 |

MOTOR |

1 |

|

|

2 |

COUPLING |

1 |

STS304 |

|

3 |

BRACKET |

1 |

FRP |

|

4 |

ANCHOR BASE |

1 |

SS41 |

|

5 |

PUMP SHAFT |

1 |

STS304+FRP |

|

6 |

CASING |

1 |

FRP |

|

7 |

REAR COVER |

1 |

FRP |

|

8 |

IMPELLER |

1 |

FRP |

|

9 |

IMPELLER NUT |

1 |

FRP |

DIMENSION LIST(mm)

|

MODEL |

A |

B |

C |

D |

E |

kW |

| NSP 4215 | 80 | 245 | 259 | 584 | 185 | 0.75 |

| NSP 4220 | 80 | 265 | 315 | 660 | 220 | 1.5 |

| NSP 5415 | 80 | 265 | 315 | 660 | 220 | 1.5 |

| NSP 5420 | 80 | 265 | 346 | 691 | 220 | 2.2 |

| NSP 5430 | 80 | 295 | 330 | 705 | 250 | 3.7 |

| NSP 6515 | 90 | 295 | 346 | 731 | 230 | 2.2 |

| NSP 6520 | 90 | 295 | 330 | 715 | 230 | 3.7 |

| NSP 6530 | 90 | 295 | 379 | 764 | 280 | 5.5 |

| NSP 8615 | 90 | 295 | 330 | 715 | 240 | 3.7 |

| NSP 8620 | 90 | 295 | 379 | 764 | 240 | 5.5 |

| NSP 8630 | 100 | 295 | 417 | 812 | 275 | 7.5 |

| NSP 1815 | 100 | 330 | 417 | 847 | 260 | 7.5 |

| NSP 1820 | 100 | 330 | 474 | 904 | 260 | 11 |

| NSP 1830 | 100 | 370 | 518 | 988 | 320 | 15 |

| NSP 1215 | 125 | 360 | 474 | 959 | 300 | 11 |

| NSP 1225 | 125 | 360 | 518 | 1003 | 300 | 15 |

| NSP 1235 | 125 | 400 | 558 | 1083 | 320 | 18.5 |

| NSP 1515 | 120 | 380 | 518 | 1018 | 320 | 15 |

| NSP 1525 | 120 | 380 | 558 | 1058 | 320 | 18.5 |

| NSP 1535 | 150 | 430 | 596 | 1176 | 375 | 30 |

| NSP 2025 | 150 | 430 | 596 | 1176 | 360 | 30 |

| NSP 2035 | 150 | 430 | 651 | 1231 | 420 | 37 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Choi, Min-ho

- Address

- 494-1, Wongdang-dong, Seo-gu, Incheon, Korea

- Product Category

- Pumps,Water Heaters

- No. of Total Employees

- 1-50

- Company introduction

-

Kumkang machinery is an adventure corporation and has advanced technology. This corporation is making FRP pump and having worldwide level technology of removing air pocket in FRP components and carried out research project of political importance development of the Ministry of science and technology.

The FRP pump is excellent in resistance to chemical(acid, alkali), heat and abrasion, so it is used for all kinds of chemistry.

- Main Product