Deliquescent Air Dryer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Bauman Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Deliquescent Air Dryer | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

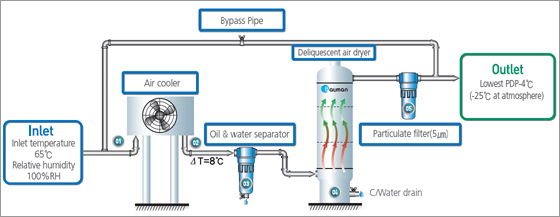

Feature of the pistonMate Series

- After cooler + Oil & water separator + Deliquescent dryer + Filter + High liquid level warning horn + Bypass pipe

- Minimum pressure dew point -4°C (-25°C at atmosphere)

- Oil removal feature

- 5μm particle removal filter

- Pulsartion block function through small piston compressors

- Low initial investment & maintenance costs

- Does not require separate pipe work

- Minimal pressure loss (less than 1%)

- Uses non-toxic desiccant (eco-friendly desiccant)

- Overcomes limitations of installation site (outdoor installation at temperatures of -20°C possible)

PistonMate Specifications

|

Sepcification

|

Flow

|

Dimension

|

Weight

|

In/Out

|

Initial filling volume of desiccant

|

Consumption volume of desiccant

|

Cooler

|

|

Model

|

Nm3/Min

|

L x W x H(mm)

|

kg

|

mm

|

kg

|

kg

|

(V/Ph/Hz)

|

|

PistonMate 50

|

0.65

|

560 x 620 x 1,245

|

46

|

15A

|

23

|

12

|

220/1/50~60

|

|

PistonMate 75

|

0.98

|

560 x 620 x 1,245

|

48

|

15A

|

27

|

17

|

220/1/50~60

|

|

PistonMate 100

|

1.3

|

650 x 750 x 1,315

|

72

|

20A

|

52

|

24

|

220/1/50~60

|

|

PistonMate 150

|

1.95

|

650 x 750 x 1,415

|

76

|

20A

|

68

|

37

|

220/1/50~60

|

- Annual average inlet temp. 24°C or less at operating pressure 7 kg/cm2 & operating time 15 hr/day (Max. inlet temp. 38°C)

- Design pressure 9.9 kg/cm2, Maximum operating pressure 9.0 kg/cm2 (If pressure of 10 kg/cm2 or higher is required, customized units are available)

- There Specifications may be modified to improve quality.

- Deliquescent air dryer was designed to drain out a condensate water manually inside of vessel. Auto drain valve EDV15 can be supplied by optional requirement for user convenience only.

- Deliquescent air dryer desiccant (DOL, SP) should be protected from oil through the filter(0.01μm), When an oil comes into desiccant bed, the desiccant performance may not be guaranteed.

Flow Diagram

- Maximum exit temperature of 65°C from the receiver tank of the piston compressor

- Maximum exit temperature of 38°C from after cooler, a lot of water mist produced.

- Water & oil mist removed

- Non-powered deliquescent dryer using Dry-O-Life(DOL), Below 55%RH, Min. PDP -4°C ISO8573-1 ll, lll class compressed air

- 5μm particle removal filter installed, removes desiccant dust and particles

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim Yun-chul

- Address

- 553-6 Midong-ri, Iwon-myeon, Okcheon-gun, Chungchongbuk-do, 373-861, Korea

- Product Category

- Hand Tools

- No. of Total Employees

- 51-100

- Company introduction

-

Founded in 1999, Bauman Co., Ltd. has focused on developing compressed air purification systems, and became the first Korean company to successfully localize the deliquescent air dryer through a partnership with Vanair Inc., U.S. specialist in the field.

Bauman continues to develop new and innovative air dryer systems by constantly addressing and improving the limitations of traditional air dryers.

The deliquescent air dryer can be installed in locations that can not accommodate traditional air dryers.

The dryers do not require a power source, enabling energy cost savings and contributing to the operator's competitive capabilities.

In addition, Bauman is preparing the foundations for overseas exports and expansion through the development of eco-friendly desiccants.

- Main Product

Related Products

UIM2901-5A MACH3 break out board for CNC

Small Sirocco Fan(TIS-190FS, TIS-190FT)

,_Smartphone_dryer,_heating_mobile_2.jpg)

Mobile Dryer, Smartphone dryer, heating chamber(RG-202)

12V KIOSK THERMAL Printer Mechanism(Module) and Board 2inch

Portable line boring machine, Elsa Supercombinata EASY Compact