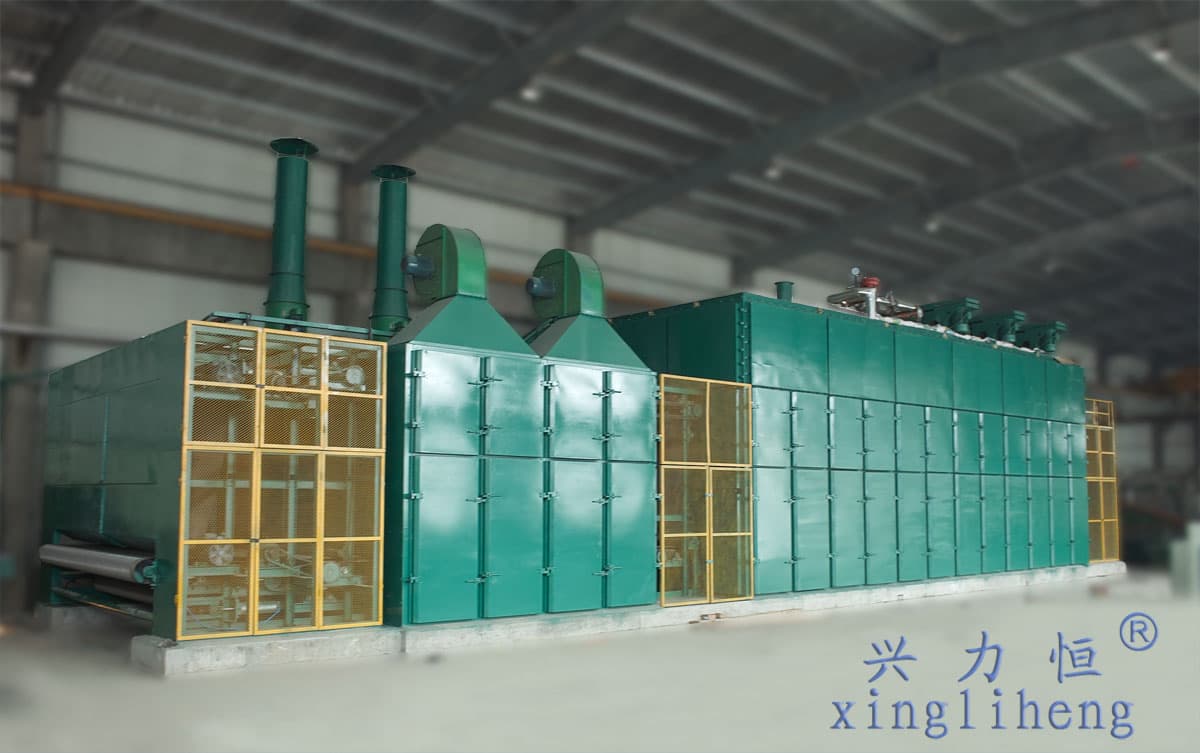

BS Series Stainless Steel Mesh-belt Veneer Dryer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- LIHENG

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Changshu Xingliheng Wood Machinery Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | BS Series Stainless Steel Mesh-belt Veneer Dryer | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Wood Based Panels Machinery Other Woodworking Machinery |

Ingredients | - |

| Keyword | veneer dryer , woodworking machine , veneer drying machine , veneer net-belt drying machine | Unit Size | - |

| Brand name | LIHENG | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Usage:

This Veneer dryer is mainly used to dry rare furniture veneers, sliced veneers, surface veneers of parquet and so on.

Characteristics:

1. Expensive stainless mesh-belt with dense mesh has been adopted to dry veneers and make them tidy and clean on surface.

2. “S” type transportation in this dryer ensures required planeness and degree of finish on veneers.

3. Air circulation system of wind pressure style and centrifugal blowers which have been mounted on top have been used. High wind pressure and large air volume can be reached.

4. Radiator is made of steel and aluminum which has the advantage of good heat conduction and large radiating area.

5. The air flow acts on the veneers evenly by ways of circulating horizontally and sprayed vertically.

6. Optional drying speed and heating temperature according to the thickness and moisture content of veneers is available by the individual controls on high-temperature and low-temperature areas.

7. Equipped with Mitsubishi branded inverter, ABB motors and SpiraxSarco steam trap, this veneer dryer enjoys high performance.

8. Drying area and cooling area are connected by brush roller instead of mesh-belt which will save more energy on both heating and cooling.

9. Two ways of heating including oil type and steam type.

Technical parameters:

|

Items Model |

BS100A-3000/4500 |

|

Working width mm |

2800~4200 |

|

Layers of deck |

1 |

|

Length of heating room mm |

3X2000+3X2000=12000 |

|

Length of cooling room mm |

2X2000=4000 |

|

Total motor power Kw |

100/122 |

|

Transportation motor power Kw |

7.5X2=15 |

|

Air heater power Kw |

6X11=66/8X11=88 |

|

Cooling fan power Kw |

2X5.5+2X4=19 |

|

Transportation speed m/min |

2~20 |

|

Main roller |

12X∮1000/16X∮1000 |

|

Compressed air pressure Mpa |

0.4~0.6 |

|

Compressed air consumption m³/h |

1.2 |

|

Heating medium |

moist steam or heat conduction oil |

|

Steam pressure Mpa |

0.6~1.2 |

|

Drying temperature ℃ |

80~140(Automatically adjusted after setting) |

|

Heat consumption Kcal/h |

120*104/165*104 |

|

Drying thickness of veneer mm |

0.2~2.5 |

|

Initial moisture content % |

75 |

|

Final moisture content % |

10±2 |

|

Drying capacity m³/h |

0.5~1 |

|

Loading rate % |

85 |

|

Dimensions: LXWXH mm |

23200/28200X4850/6350X4700 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Changshu Xingliheng Wood Machinery Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

12

- President

- Mr. Zhou

- Address

- Caoge Village, Haiyu Town, Changshu City, Jiangsu Province, China

- Product Category

- Other Woodworking Machinery,Woodworking Machinery,Woodworking Machinery Parts

- No. of Total Employees

- 51-100

- Company introduction

-

Changshu Xingliheng Wood Machinery Co., Ltd is located in the famous historic and cultural city-Changshu, which is near to Shanghai, has the beautiful scenery and convenient transportation. We are professional in designing and producing woodworking machines including 2-layer, 3-layer mesh belt veneer dryer, roller veneer dryer, mesh-roller combined veneer drying machine, veneer peeling lathe, shearing knife grinder, double hydro-cylinder lifting table and so on. All productions have been approved by CE certificate by our excellent quality and safety in use. The enterprise provides very high quality productions with the backup of rich experiences and powerful technology. We have a management and supervision system on the production developing, designing, testing, manufacturing, marketing and after sales services. We stick to the national standards, work hard to catch up with international advanced technology and improve the quality management system as well as our services. Specially designed full solution on production process will be offered to clients to save the investing costs. We sincerely hope to forge ahead with all our clients from home or abroad hand in hand to build a brilliant future. Welcome to visit us!

- Main Markets

-

Australia

Australia

China

China

Colombia

Colombia

Indonesia

Indonesia

Philippines

Philippines

Romania

Romania

Russia

Russia

Singapore

Singapore

Sri Lanka

Sri Lanka

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

U.A.E.

U.A.E.

Ukraine

Ukraine

Uruguay

Uruguay

- Main Product