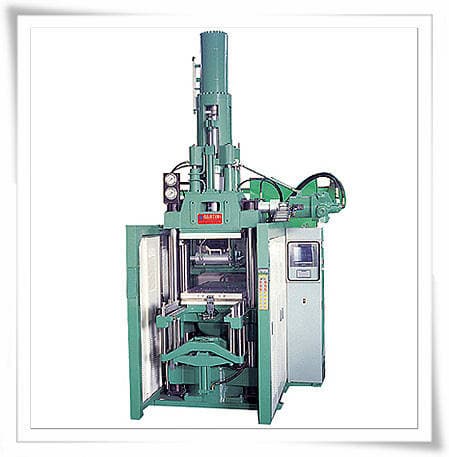

Vertical Injection Rubber Molding Press

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Plastic Product Making Machinery

Shinchang Precision Industrial Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Vertical Injection Rubber Molding Press | Certification | - |

|---|---|---|---|

| Category | Plastic Product Making Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Feature

- Minimized breakdowns and increased the life time of machines by using slide method by combining LM Bearing and Disk Spring.

- Reduced next work preparation times by preventing scotching of remaining rubbers inside of nozzle by speedy cooling.

- Maintenance in nozzle part is easy by adopting one-touch dismantling method in the upper heating plate.

- Be capable of reducing setting times of operating conditions of same items by storaging operating conditions(20set) by Touch Screen Monitor and prompt remedy to the breakdowns and operation is possible by preserving messages(195items) for the operations and defects.

- Can be connecting with computer so it can be use in the office and controling of operating data is very efficient.

Application

- Produce automobile & industrial rubber part

Specification

|

Item

|

Model

|

|||

|

SC-0.3/0.5- 75

|

SC-1.0/1.6- 75

|

SC-1.6/3.0- 75

|

SC-3.0/4.0- 75

|

|

| Power (Ton) | 75 | 150 | 300 | 450 |

| Clamping System | Simple Ram | Block And Ram | ||

| Heating Plate Size (mm) |

500 x 400 | 550 x 550 | 650 x 650 | 700 x 800 |

| Heater Capacity(kW) | 5 X 2 | 6 x 2 | 8.5 x 2 | 13 x 2 |

| Daylight Opening(mm) | 450 | 550 | 750 | 800 |

| Clamping Stroke(mm) | 350 | 400 | 550 | 600 |

| Min Mold Thickness(mm) |

100 | 150 | 200 | 200 |

| Mold Opening Force (Ton) |

2.3 | 5 | 7 | 12 |

| Injection Pressure (kg/cm2 ) |

1600 - 2000 | |||

| Injection Volume (L) |

0.3 0.8 | 1.0 1.6 | 1.0 1.6 2.0 | 3.0 4.0 |

| Temperature Regulator |

1Set | 2Set | ||

|

Overall |

1050x2100x3400 | 1950x2300x3500 | 2150x2640x4500 | 2300x2800x4800 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Yongha Kim

- Address

- 905-7 Woram-dong, Dalseo-gu, Daegu, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Shinchang Precision Industrial Co., Ltd. was founded as a specialized manufacturer of rubber mold in July1977 and has developed superior new products through continuous research development.

At present, we are manufacturing Automatic Rubber Molding Press and Rubber Mold, equipment for rubber components used for automobiles and industrial application.

We have settled consistent system from develoment to automation of manufacturing process and quality control through cooperation of all staffs for 22 years since establishment.

By doing so, we can produce superior automatic rubber molding press and rubber mold and lead other makers in market share.As a result, we were awarded from the Premier for contributing to development of superior capital goods in 1999.

We will make every effort to contribute development of rubber component industry for automobile and industrial application with incessant research based on accumulated technology and systematic quality control.Thank you.

- Main Product

Related Products

PVC CASTING TYPE MACHINERY PVC PRODUCTION LINE

keli szcx injection blow molding machine

PVC decorative film

RUBBER GRIP MOLD

3d film for Sublimation