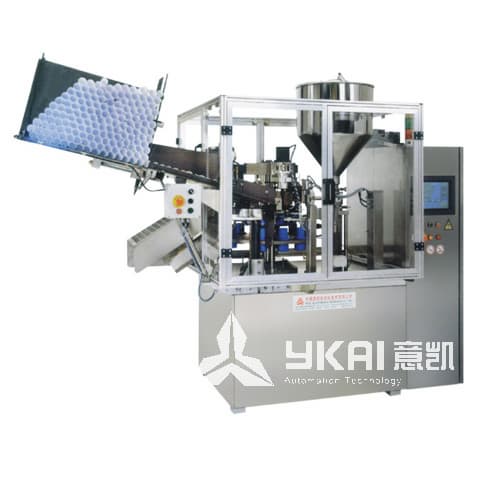

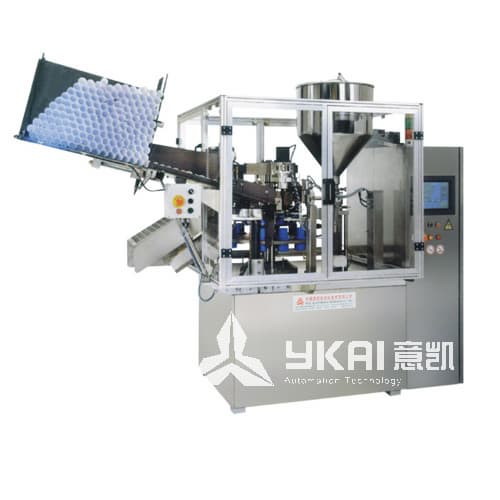

Soft Tube Filling Sealing Machine (SGF-50)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- wuxi YK

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Packaging Machines

Wuxi YK Automation Technology Co., Ltd.

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Soft Tube Filling Sealing Machine (SGF-50) | Certification | - |

|---|---|---|---|

| Category | Packaging Machines | Ingredients | - |

| Keyword | filling , sealing | Unit Size | - |

| Brand name | wuxi YK | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Wuxi YK Automation Technology Co., Ltd.

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

12

- President

- songhuajiang

- Address

- No. 2855, Jiaoyang Road, An Town, Xishan District, Wuxi City.

- Product Category

- Other Machinery & Industry Equipment,Packaging Machines,Seals

- No. of Total Employees

- 101-500

- Company introduction

-

Wuxi YK Automation Technology Co., Ltd. is specialized in the research, design, manufacture, sale and service of liquid, lotion, cream, tooth paste and adhesive machineries such as Cosmetics and Pharmaceuticals Complete Vacuum Emulsifying Mixers, High-shear Emulsifiers, Double Planet Mixers, Mixers, Mixing Tanks, Dissolvers, Mills and Turnkey projects. Developed from a mixer manufacturer-Wuxi Jianuo Delicate Chemical Equipment Factory, YK is specialized in designing, developing and manufacturing mixers with about 12 years' history. On the basis of rich experience in manufacturing, YK increases technology and production capacity greatly with introduced European and North American technology. Up to now, we have developed various world-class machines which sell well both in domestic and international markets. We have gained a high appreciation from our customers. YK has a registered capital of 5, 000, 000 U. S. Dollars and covers an area of 14, 000 square meters. Meanwhile, we have obtained ISO9001: 2000 certificate, CE certificate and the manufacturing license. YK has been developing new businesses continuously in industries such as cosmetics, pharmaceuticals, food, adhesives, petroleum, lubricants and pesticide. Adhering to the guidelines "To improve product quality, to satisfy customers, to perfect systems, to develop and innovate new technology and products", YK makes efforts continuously to realize a perfect unification of economy and social benefit with our operation attitude of "Integrity, Cooperation, Study and Innovation". Your satisfaction is our pursuit. YK team will provide you with excellent products and all-round services as always!

- Main Markets

-

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

Enterpack(At, semi auto food packaging machine)

Folding Carton Machine / Folder Gluer (LION)

Heavy Duty Pouch Laminator TOFO 330R6

PAPER PLATE MACHINE

Lipstick Molding Machine (LSR-1200S)