Extrusion Dies for Plastic

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

OneTech Corporation

- Verified Certificate

-

12

| Product name | Extrusion Dies for Plastic | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Product Profile

|

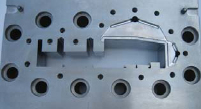

Extrusion Dies For Plastic Profiles

|

|

|

|

|

Extrusion Dies : Assembly View

|

Extrusion Dies : Assembly View

|

|

OneTech guarantee the tool life of 650,000 meter-runs

|

|

|

Calibrators for Plastic Extrusion

|

|

|

|

|

Vacuum & Cooling Calibrator

|

|

|

Our calibration system is designed and manufactured to be user friendly.

|

|

|

Cooling Box Plastic Extrusion

|

|

|

|

|

Cooling Bath for Main Profiles

|

Cooling Box for Auxiliary Profiles

|

|

Standard cooling baths by profile dimension allow customer to reduce time for exchanging tooling in extrusion lines and cost-down of tooling. All bath made of anodized Aluminum and poly-carbonate plates have a good strength and durability.

|

|

|

High-Performance Extrusion Tooling

|

|

|

|

|

High Speed Extrusion Tooling

|

High-Output Extrusion Tooling

|

|

On the customers' demand we produce high performance extrusion tooling possible to produce in a large scale up to 700 kg/hr output.

|

|

|

Multi-Cavity Extrusion Tooling

|

|

|

|

|

4-Cavity Extrusion Tooling

|

6-Cavity Extrusion Tooling

|

|

Multi-cavity extrusion tooling can be applied to auxiliary profiles for mass production and maximum efficiency of extruder.

|

|

|

Co-extrusion Tooling

|

|

|

|

|

Gasket Co-extrusion Tooling

|

2-Tone Color Extrusion Tooling

|

|

The latest co-extrusion technology makes a great contribution to the cost down and production improvement of our customer.

|

|

|

WPC Extrusion Tooling

|

PC+ ASA Coextrusion Tooling

|

|

|

|

WPC Extrusion Tooling

|

Antenna Radome Extrusion Tooling

|

|

OneTech develops the various kind of extrusion tooling for the demand of customers.

|

|

|

Sheet & Board Extrusion Tooling

|

Soft PVC Extrusion Tooling

|

|

|

|

Composite Panel Extrusion Tooling

|

Gasket Extrusion Tooling

|

|

OneTech also produces many kinds of extrusion tooling as following

|

|

|

O.E.M Production of PVC Profiles

|

|

|

|

|

Profile Extrusion Lines

|

Profile Samples

|

|

Three modern extrusion lines are installed in OneTech and they are services to preliminary test before delivery and O.E.M production.

|

|

Production Range of Tooling

|

Tooling Type

|

Performance

|

Tooling Specification

|

Profile Example

|

REM Arks

|

||||||

|

Output

|

Speed

|

Dies

|

Dry Calibrator

|

Cooling Dick

|

Cooling Bath

|

Total Cooling Length

|

||||

|

Type-A

|

DS-HS

|

700

|

2 x 2.5

|

350 x 200 x 500

|

400 x 2 x 2

|

20 x 80

|

3M+3M

|

6,800

|

4 Track Frame (2.5~3.5kg/m)

|

|

|

HS

|

450

|

2.8

|

350 x 200 x 300

|

400 x 2

|

20 x 40

|

3M+3M+2M

|

8,800

|

|||

|

TS

|

250

|

1.5

|

350 x 200 x 300

|

400 x 1

|

20 x 30

|

3M

|

3,850

|

|||

|

Type-B

|

DS

|

450

|

2 x 2.5

|

250 x 200 x 450

|

400 x 2 x 2

|

20 x 68

|

3M+3M

|

6,800

|

2-Track Frame (1.5~2.5kg/m)

|

|

|

HS

|

450

|

3.5

|

250 x 200 x 250

|

400 x 2

|

20 x 34

|

3M+3M+2M

|

8,800

|

|||

|

TS

|

250

|

2.5

|

250 x 200 x 250

|

400 x 2

|

20 x 26

|

2M+2M

|

4,800

|

|||

|

Type-C

|

DS-HS

|

450

|

2 x 4.5

|

180 x 180 x 400

|

400 x 2 x 2

|

20 x 68

|

3M+3M+2M

|

8,800

|

Sliding Frame(0.5~1.5kg/m)

|

|

|

HS

|

300

|

5.0

|

180 x 180 x 250

|

400 x 2

|

20 x 34

|

3M+3M+2M

|

8,800

|

|||

|

TS

|

180

|

3.0

|

180 x 180 x 200

|

400 x 2

|

20 x 26

|

3M+3M

|

6,800

|

|||

|

Type-D

|

6S

|

200

|

6 x 4.5

|

300 x 160 x 300

|

400 x 1

|

200 x 1

|

2M

|

2,400(2,450)

|

Glazing Bead Interlock (0.1~0.5 kg/m)

|

|

|

4S

|

180

|

4 x 4.5

|

250 x 160 x 250

|

400 x 1

|

200 x 1

|

2M

|

2,400(2,450)

|

|||

|

DS

|

120

|

2 x 5.0

|

160 x 160 x 200

|

400 x 1

|

200 x 1

|

2M

|

2,400(2,450)

|

|||

|

TS

|

90

|

3.0

|

160 x 160 x 200

|

400 x 1

|

200 x 1

|

2M

|

2,400(2,450)

|

|||

DS : Double Strand Tooling,

HS : High Speed Tooling,

TS : Typical Single Strand Tooling,

4S : 4-Strand Tooling,

6S : 6-Strand Tooling Performance of extrusion toolings is based on the results made by OneTech Co., and is eventually depend upon the capacity of customers' machinery. Detailed specification of toolings can be changed according to the demand or machinery of customers. REM ARKS

Equipment List

|

Nr

|

Description

|

Specification

|

Model Nr

|

Maker

|

Issued Year

|

|

BSM-1

|

BAND SAWING MACHINE

|

Work Range(BxH)= 500x500

|

WBS-500S

|

Wongong Machinery

|

2001

|

|

CTM-1

|

CONTOUR MACHINE

|

Work Range(BxH)= 360x180

|

DV-360

|

Daese Precision

|

2003

|

|

HLM-1

|

HORIZONTAL LATHE

|

Bed D=530, C/C=1,550

|

TIPL-5

|

Tongil Heavy Ind.

|

2004

|

|

UMM-1

|

UNIVERSAL MILLING MACHINE

|

Work Range(BxWxH)= 1,400x600x700

|

KMB-U-5

|

Kiheung Machinery

|

2004

|

|

UMM-2

|

UNIVERSAL MILLING MACHINE

|

Work Range(BxWxH)= 700x300x400

|

MAHO-1.5

|

Deckel Maho AG (Ger.)

|

2003

|

|

UMM-3

|

UNIVERSAL MILLING MACHINE

|

Work Range(BxWxH)= 820x300x450

|

40VA

|

Toong-Chi (Taiwan)

|

2004

|

|

UMM-4

|

UNIVERSAL MILLING MACHINE

|

Work Range(BxWxH)= 800x300x400

|

2UMB

|

NIGATA (Japan)

|

2004

|

|

SGM-1

|

SURFACE GRINDING MACHINE

|

Work Range(BxWxH)= 525x750x695

|

YGS-65A

|

Youil Grinding

|

2001

|

|

FGM-1

|

FORM GRINDING MACHINE

|

Work Range(BxWxH)= 520x250x450

|

ACE-2000

|

Ace Engineering

|

2002

|

|

FGM-2

|

FORM GRINDING MACHINE

|

Work Range(BxWxH)= 520x250x450

|

WJ-2045

|

Woojin Macinery

|

2001

|

|

FGM-3

|

FORM GRINDING MACHINE

|

Work Range(BxWxH)= 520x250x450

|

JFG-520M

|

Jinyoung Precision

|

2004

|

|

MCT-1

|

MACHINING CENTER

|

Work Range(BxWxH)= 2,000x800x650

|

NASU-V830

|

Namsun Machinery

|

2008

|

|

MCT-2

|

MACHINING CENTER

|

Work Range(BxWxH)= 1,020x510x620

|

MYNX-500

|

Daewoo Machinery

|

2002

|

|

MCT-3

|

MACHINING CENTER

|

Work Range(BxWxH)= 500x380x300

|

K04B-0069

|

Fanuc Korea

|

2002

|

|

SDM-1

|

SUPER DILLING MACHINE

|

Work Range(BxWxH)= 350x250x350

|

JS-3B

|

Jinyoung Precision

|

2001

|

|

SDM-2

|

SUPER DILLING MACHINE

|

Work Range(BxWxH)= 350x250x350

|

ETC-430B

|

Enter Techno Co.

|

2007

|

|

WEDM-1

|

WIRE CUTTING MACHINE

|

Work Range(BxWxH)= 300x500x270

|

LDM-55

|

Japax (Japan)

|

2002

|

|

WEDM-2

|

WIRE CUTTING MACHINE

|

Work Range(BxWxH)= 300x500x270

|

KEM-500A

|

Intertechno

|

2004

|

|

WEDM-3

|

WIRE CUTTING MACHINE

|

Work Range(BxWxH)= 300x400x400

|

ROBOFIL-310

|

Charmilles (Swiss)

|

2002

|

|

WEDM-4

|

WIRE CUTTING MACHINE

|

Work Range(BxWxH)= 570x420x230

|

AQ327L

|

Sodick (Japan)

|

2005

|

|

WEDM-5

|

WIRE CUTTING MACHINE

|

Work Range(BxWxH)= 700x500x650

|

AQ750LH

|

Sodick (Japan)

|

2009

|

|

EDM-1

|

ELECTRIC DISCHARGING MACHINE

|

Work Range(BxWxH)= 300x200x250

|

JDE-30S

|

Jinyoung Precision

|

2002

|

|

EDM-2

|

ELECTRIC DISCHARGING MACHINE

|

Work Range(BxWxH)= 300x200x250

|

JDE-31S

|

Jinyoung Precision

|

2001

|

|

RDM-1

|

RADIAL DRILLING MACHINE

|

Work Range(BxWxH)= 1,100x750x710

|

DA-1500R

|

Daewoo Macinery

|

2006

|

|

EHM-1

|

EXTRUDE HONING MACHINE

|

Work Range(BxWxH)= 1,100x750x710

|

-

|

Youngam Ind.

|

2001

|

|

GDM-1

|

GUN DRILLING MACHINE

|

Work Range(DxL)= D3-12xL=500

|

-

|

Youngam Ind.

|

2002

|

|

EXT-1

|

PVC EXTRUSION LINES

|

D88 Twin Screw Extruder, Cali Table=10M

|

HS-88

|

Heesungtech

|

2004

|

|

EXT-2

|

PVC EXTRUSION LINES

|

D88 Twin Screw Extruder, Cali Table=7M

|

HS-88

|

Heesungtech

|

2004

|

|

EXT-3

|

PVC EXTRUSION LINES

|

D88 Twin Screw Extruder, Cali Table=7M

|

HS-88

|

Heesungtech

|

2004

|

|

EXT-4

|

PVC EXTRUSION LINES

|

D90 Twin Screw Extruder, Cali Table=7M

|

HS-90

|

Min-Chang Machinery

|

2008

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Byoungrho Park

- Address

- 178, Wanju-Sandan-3ro, Bongdong-eup, Wanju-gun, Jeonbuk-do, Korea

- Product Category

- Plastic Product Making Machinery

- No. of Total Employees

- 1-50

- Company introduction

-

We, OneTech, make a great effort to satisfy your needs.

OneTech, which has produced extrusion tooling and PVC extrusion products since its outset in 2001, is playing a leading role in the industry based on its long accumulated extrusion technology and talented manpower.

We are fully committed to serving you with the best quality and technology on which we design, manufacture and produce diverse types of extrusion tooling and products including PVC window profile tooling.

We express our deep appreciation to you for supporting us all the time.

- Main Product

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)