Opaque Polymer (HIQUE 387, HIQUE 388)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

HANKUCK LATICES Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Opaque Polymer (HIQUE 387, HIQUE 388) | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Introduction

Opaque polymers HIQUE 387 & 388 are Styreneacrylic copolymer emulsions which provide opacity of emulsion paints.

HIQUE 387 & 388 have free of Alkyl Phenol Ethoxylate (APE) derivative surfactant which is known as a kind of mimic estrogen. HIQUE 387 & 388 provide the most efficient dry hiding in interior and exterior coatings.

HIQUE 387 & 388 provide a cost effective way to improve hiding while reducing raw material cost. Main advantage of HIQUE 387 & 388 is as follows.

- Low PVC paints (Gloss, Semi-Gloss, and Sheen)

. If some parts of titanium dioxide in paint are replaced, it is possible to obtain similar gloss and sheen.

. When some parts of titanium dioxide are replaced for HIQUE products, it is possible to reduce dirt pick-up by improving tackiness in the surface of the dry paint film.

. If some parts of titanium dioxide are replaced, it is possible to reduce the prime cost.

. If some parts of titanium dioxide are replaced, it is possible to obtain the paint film with better hiding. - Medium PVC and High PVC paints

. If some parts of titanium dioxide are replaced, it is possible to obtain the paint film with better hiding.

. If calcined clay is replaced, it is possible to reduce the prime

. The replacement of calcined clay may lead to the improvement in scrap resistance.

. For High PVC paints, it is also possible to reduce dirt pick-up with the reduced porosity in the paint film. - Safety and Handling

. HIQUE 387 & 388 are slightly irritating to the skin and eyes, and contact with these areas should be avoided. When handling wear impervious rubber gloves and goggles/facemask.

. For handling/operation where possible contact may occur, a safety shower and eyewash station should be available. Further detailed information can be found in the MSDS documentation. - Handling/Dosing Equipment

. It is okay if stainless steel, plastic, rubber, and glass come in contact with HIQUE 387 & 388.

. However, mild steel, copper, brass, bronze, aluminum, and zinc should be avoided to prevent polymer build-up. As HIQUE 387 & 388 are common emulsion polymers, it is recommended that you use low shear pumps (air diaphragm pumps, mono pumps, etc.) when pumping it.

. Continuous agitation is not necessary but periodic mixing will prevent slight sedimentation during long term storage. Store in a closed container at 5°C - 40°C. - Packing

. The HIQUE that comes in drums or 1 ton IBC tanks contains no biocides.

. When supplied in bulk, the shipment will contain 0.1% of biocides.

Physical Properties

| Properties | HIQUE 387 | HIQUE 388 |

| Appearance | milky white liquid | |

| Solid content | 29-31% | |

| Specific gravity | CA 1.023 | |

| pH | 9-10.5 | 8 - 9 |

| Average Particle size | CA 0.4µm | |

| Ionic Charge | Anionic | |

Rheological Properties

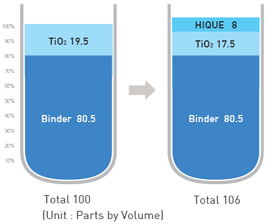

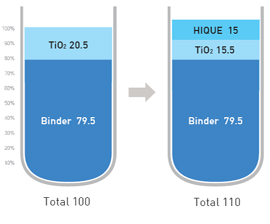

| High Gloss paints | Semi Gloss paints |

| (TiO2 : -2PVC, HIQUE: +8PVC) | (TiO22 : -5PVC, HIQUE: +15PVC) |

|

|

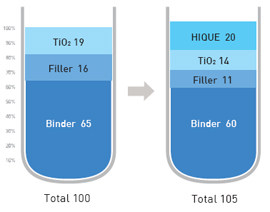

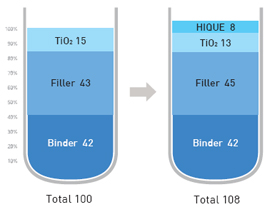

| Sheen paints | High PVC Exterior Flat paints |

| (TiO2 : -5 PVC Filler : -5 PVC Binder : -5 Vol % HIQUE: +20 PVC) | (TiO2 : -5 PVC Filler : -5 PVC Binder : -5 Vol % HIQUE: +20 PVC) |

|

|

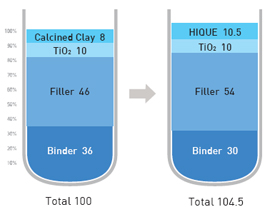

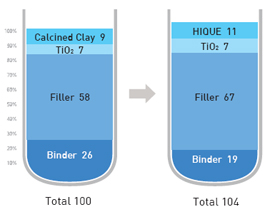

| Exterior High PVC paints | Interior High PVC paints |

| Calcined Clay → Calcium carbonate Binder(2/3 of Wt. of Calcined clay) → deduction Add HIQUE ( Same Wt. of Calcined clay) |

Calcined Clay → Calcium carbonate Binder(2/3 of Wt. of Calcined clay) → deduction Add HIQUE ( Same Wt. of Calcined clay) |

|

|

High Gloss paint Formulation Suggestion

| Component | Control HG400 | HG4041 | HG4042 | |

| Grind: | ||||

| Deionized water | 178.6 | 178.6 | 178.6 | |

| HIDIS 40 | 4 | 4 | 4 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.4 | 0.4 | 0.4 | |

| Propylene glycol | 20 | 20 | 20 | |

| AMP 95 | 0.5 | 0.5 | 0.5 | |

| Megal K14 | 1 | 1 | 1 | |

| TRONOX CR828 | 205 | 185 | 185 | |

| Let down: | ||||

| Deionized water | 100 | 80 | 80 | |

| HISOL AC115 | 434 | 434 | 434 | |

| Propylene glycol | 20 | 20 | 20 | |

| Triton CF10 | 2.4 | 2.4 | 2.4 | |

| Nopco 8034L | 0.6 | 0.6 | 0.6 | |

| Texanol | 6 | 6 | 6 | |

| Ammonia | 3 | 3 | 3 | |

| HISOL 308 | 4 | 4 | 4 | |

| HIRESOL 1800 | 20 | 20 | 20 | |

| HIQUE 387 | 40 | |||

| HIQUE 388 | 40 | |||

| Total | 1000 | 1000 | 1000 | |

| PAINT PROPERTIES PVC, % | 19.5 | 23.8 | 23.8 | |

| Total Solids, % | by weight | 48.02 | 47.22 | 47.22 |

| by volume | 31.29 | 32.76 | 32.76 | |

| Stormer, KU | 90.5 | 90.8 | 90.8 | |

| FILM PROPERTIES | Whiteness | 89.97 | 91.04 | 90.16 |

| Contrast ratio | 0.9632 | 0.9747 | 0.9664 | |

| Gloss, 60° | 58.1 | 62.4 | 60.3 | |

| Gloss, 20° | 15.7 | 17.7 | 16.9 | |

Semi Gloss paint Formulation Suggestion

| Component | Control SG500 | SG501 | SG502 | |

| Grind: | ||||

| Deionized water | 214.4 | 214.4 | 214.4 | |

| HIDIS 40 | 2 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | 0.5 | |

| Propylene glycol | 20 | 20 | 20 | |

| AMP 95 | 0.5 | 0.5 | 0.5 | |

| Megal K14 | 1 | 1 | 1 | |

| TRONOX CR828 | 200 | 170 | 170 | |

| Let down: | ||||

| Deionized water | 120 | 70 | 70 | |

| HISOL AC115 | 400 | 400 | 400 | |

| Propylene glycol | 6 | 6 | 6 | |

| Triton CF10 | 1.5 | 1.5 | 1.5 | |

| Nopco 8034L | 0.6 | 0.6 | 0.6 | |

| Texanol | 6 | 6 | 6 | |

| Ammonia | 2 | 2 | 2 | |

| HISOL 308 | 5 | 5 | 5 | |

| HIRESOL 1800 | 20 | 20 | 20 | |

| HIQUE 387 | 80 | |||

| HIQUE 388 | 80 | |||

| Total | 1000 | 1000 | 1000 | |

| PAINT PROPERTIES PVC, % | 20.4 | 29.7 | 29.7 | |

| Total Solids, % | by weight | 44.26 | 43.66 | 43.66 |

| by volume | 28.33 | 31.53 | 31.53 | |

| Stormer, KU | 90.6 | 90.8 | 90.8 | |

| FILM PROPERTIES | Whiteness | 90.55 | 91.14 | 90.93 |

| Contrast ratio | 0.9594 | 0.9718 | 0.9682 | |

| Gloss, 60° | 55.3 | 58.6 | 58.2 | |

| Gloss, 20° | 14.6 | 16.5 | 15.3 | |

Sheen paint Formulation Suggestion

| Component | Control SH433 | SH601 | SH602 | |

| Grind: | ||||

| Deionized water | 175.4 | 175.4 | 175.4 | |

| HIDIS 40 | 2 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | 0.5 | |

| Propylene glycol | 20 | 20 | 20 | |

| AMP 95 | 0.5 | 0.5 | 0.5 | |

| Megal K14 | 1 | 1 | 1 | |

| TRONOX CR828 | 200 | 160 | 160 | |

| Omya CARB 10 | 110 | 80 | 80 | |

| Let down: | ||||

| Deionized water | 100 | 67 | 80 | |

| HISOL AC115 | 350 | 333 | 333 | |

| Propylene glycol | 6 | 6 | 6 | |

| Triton CF10 | 1.5 | 1.5 | 1.5 | |

| Nopco 8034L | 0.6 | 0.6 | 0.6 | |

| Texanol | 6 | 6 | 6 | |

| Ammonia | 2 | 2 | 2 | |

| HISOL 308 | 4 | 4 | 4 | |

| HIRESOL 1800 | 20 | 20 | 20 | |

| HIQUE 387 | 120 | |||

| HIQUE 388 | 120 | |||

| Total | 1000 | 1000 | 1000 | |

| PAINT PROPERTIES PVC, % | 34.9 | 43.5 | 43.5 | |

| Total Solids, % | by weight | 52.76 | 48.51 | 48.51 |

| by volume | 29.76 | 32.71 | 32.71 | |

| Stormer, KU | 90.5 | 90.8 | 90.8 | |

| FILM PROPERTIES | Whiteness | 89.46 | 90.31 | 90.05 |

| Contrast ratio | 0.9552 | 0.9656 | 0.9623 | |

| Gloss, 60° | 9.5 | 10.1 | 10.4 | |

| Gloss, 20° | 9.8 | 19.4 | 19.2 | |

Exterior Flat paint Formulation Suggestion

| Component | Control EF100 | EF710 | EF711 | |

| Grind: | ||||

| Deionized water | 152 | 152 | 152 | |

| HIDIS 40 | 2 | 2 | 2 | |

| Triton CF10 | 1 | 1 | 1 | |

| Nopco NXZ | 2 | 2 | 2 | |

| Natrosol 250HBR(3%) | 65 | 65 | 65 | |

| Megal K14 | 2 | 2 | 2 | |

| Ti-PURE R902 | 100 | 100 | 100 | |

| Talc #400 | 90 | 90 | 90 | |

| Omya CARB 10 | 210 | 260 | 260 | |

| Satitone W | 50 | |||

| Let down: | ||||

| Deionized water | 90 | 70 | 70 | |

| HISOL AC53 | 210 | 170 | 170 | |

| Propylene glycol | 10 | 10 | 10 | |

| Nopco NXZ | 3 | 3 | 3 | |

| Texanol | 5 | 5 | 5 | |

| Ammonia | 4 | 4 | 4 | |

| HISOL 307 | 4 | 4 | 4 | |

| HIQUE 387 | 60 | |||

| HIQUE 388 | 60 | |||

| Total | 1000 | 1000 | 1000 | |

| PAINT PROPERTIES PVC, % | 63.3 | 71.5 | 71.5 | |

| Total Solids, % | by weight | 57.21 | 57.21 | 57.21 |

| by volume | 27.11 | 28.31 | 28.31 | |

| Stormer, KU | 100.4 | 100.6 | 100.6 | |

| FILM PROPERTIES | Whiteness | 84.56 | 85.39 | 85.63 |

| Contrast ratio | 0.9521 | 0.9542 | 0.9582 | |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM MOON SOO

- Address

- #321-21,Gongdan-Dong ,, Gumi-Si, Gyeongsangbuk-do,

- Product Category

- Other Paint & Coatings

- Company introduction

-

Hankuck Latices Co., Ltd. (HLC) has been researching and developing, producing, and selling additives for the Korean domestic and international water based paint and paper coating industry for over twenty years. Following stringent operating principles, HLC develops new production processes and products using environmentally friendly methods, constantly increases reliability to domestic and global customers through ever improving services, promotes the welfare of employees and their families, and encourages social responsibility through profit generation.

- Main Markets

-

Egypt

Egypt

Greece

Greece

India

India

Malaysia

Malaysia

Viet Nam

Viet Nam

- Main Product

_POWDER_2.jpg)