HEUR Thickener HIRESOL

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

HANKUCK LATICES Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | HEUR Thickener HIRESOL | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Introduction

HIRESOL grades(80, 85, 500, 370, 180, 200, 1800 and 2000)are Nonionic Urethane associative thickeners(HEUR) designed for thickening of water base coatings.

HIRESOL 80, 500, 180, 200, 1800 and 2000 free of solvent are suitable to manufacturing of low VOC water based paints and other coatings and they provide the most versatile means of formulating to desired film build, flow and high shear viscosity to prevent the roll spatter in water based paints. Thickening mechanism of HIRESOL HEUR Thickeners is due to an interaction of the thickener with other hydrophobic surfaces.

Thus, the more hydrophobic and the finer the particles of latex polymers, the more efficient the thickener will be. Therefore, HIRESOL 1800 and 2000 are the most efficient thickening with fine particle size Acrylic binder and Styrene-Acrylic copolymer binder paints. The main thickening mechanism of HIRESOL HEUR Thickeners is the association between thickener and binder/pigment colloid particles. Thus, associative network minimized volume restricted flocculation that is a typical phenomenon of non-associative thickener system. Reducing of volume restricted flocculation imparts the gloss development and the film integrity to the emulsion paints. The Main Advantages of HIRESOL HEUR Thickeners are the following:

Advantages

- Excellent paint flow and leveling.

- High gloss development.

- Because of solvent free, designed for low VOC paints(HIRESOL 80, 500, 180, 200, 1800 and 2000).

- Low odor

- Low formation of bubbles when manufacturing.

- Excellent viscosity stability in long term storage.

- Provides anti-settling properties and reduces syneresis (Case of medium to high shear grade).

- High film build and better applied hiding.

- Excellent spatter resistance.

- Resistance to microbes and its enzymes.

- Because of low viscosity, easy to handle.

Physical Properties

| Properties | Appearance | Solid contents (%) |

Volatile component |

Specific Gravity at 25°C |

Viscosity(Cps) at 25°C |

P H | |

| HIRESOL 85 | Slightly hazy viscous liquid |

24-26 | Water/BDG =80/20 | 1.032-1.036 | 2000-5500 | 6-8 | Nonionic |

| HIRESOL 370 | 18-19 | Water/ BDG=75/25 | 1.030-1.034 | 1000-3000 | 4-6 | ||

| HIRESOL 80 | 20-21 | Water | 1.040-1.045 | 2000-5000 | 5-8 | ||

| HIRESOL 500 | 18-20 | Water | 1.040-1.045 | 2000-4000 | 5-8 | ||

| HIRESOL 180 | 24-26 | Water | 1.040-1.045 | 2500-6000 | 6-8 | ||

| HIRESOL 200 | 24-26 | Water | 1.040-1.045 | 1500-4000 | 6-8 | ||

| HIRESOL 1800 | 19-21 | Water | 1.040-1.045 | 1000-4000 | 6-8 | ||

| HIRESOL 2000 | 19-21 | Water | 1.040-1.045 | 1000-4000 | 6-8 |

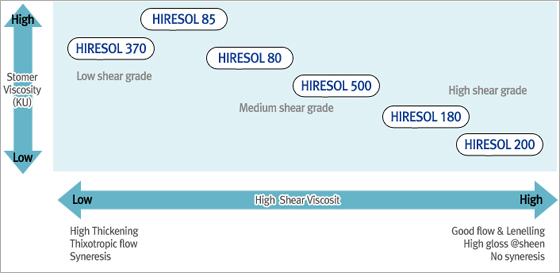

Rheological Properties

Formulation Guide

- As mentioned, when HIRESOL HEUR Thickeners are applied to hydrophobic (latex Ex. Acrylic emulsions, Styrene-Acrylic copolymer emulsion) based paints, it's more effective for thickening of the paints. And with fine particle size (latex higher hydrophobic surface) HIRESOL 1800 and 2000 are more effective.

- Higher volume solids of the paint thickening with HIRESOL HEUR Thickeners provides the more effective thickening because of the more sites for association.

- Generally, being adding of surfactant reduces the thickening effect. The higher the HLB of the surfactant used, the higher the reduction of the viscosity of the paint will be.

- Coalescing agent of Texanol has little or no effect on KU viscosity of an associative thickener paints. EG and PG used as wet edge agent in emulsion paints have the least effect, while Butyl Carbitol have the greatest effect to the viscosity of the paints.

- The emulsion paints thickened with HIRESOL 1800 and 2000 associative thickener show excellent paint flow and higher high-shear viscosity. To design the rheology balance of the emulsion (paints In-can viscosity, sagresistance), combination with low shear of HIRESOL (thickener HIRESOL 85, 80, 370) or with HISOL 308 is recommended.

- Instead of combination with the high shear HIRESOL (thickeners HIRESOL 1800, 2000) and the low shear HIRESOL (thickeners HIRESOL 85, 80, 370), Medium shear thickener HIRESOL 500 is recommended to minimize the syneresis of paints.

Sheen Paints based on Acrylic emulsion binder

| Components | SH800 | SH801 | SH802 | SH803 | |

| Grind | Deionized Water | 170.9 | 170.9 | 170.9 | 170.9 |

| Propylene glycol | 20 | 20 | 20 | 20 | |

| HIDIS 40 | 2 | 2 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | 0.5 | 0.5 | |

| AMP95 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Mergal K14 | 1 | 1 | 1 | 1 | |

| TRONOX CR828 | 140 | 140 | 140 | 140 | |

| OMYA CARB10 | 30 | 30 | 30 | 30 | |

| Let down | Nopco 8034L | 0.6 | 0.6 | 0.6 | 0.6 |

| HISOL AC115 | 380 | 380 | 380 | 380 | |

| Deionized water | 113 | 109 | 111 | 102 | |

| Propylene glycol | 6 | 6 | 6 | 6 | |

| HIRESOL 85 | 7 | - | - | - | |

| HIRESOL 80 | - | 11 | - | - | |

| HIRESOL 370 | - | - | 9 | - | |

| HIRESOL 500 | - | - | - | 18 | |

| Ammonia | 2 | 2 | 2 | 2 | |

| Texanol | 6 | 6 | 6 | 6 | |

| HIQUE 387 | 120 | 120 | 120 | 120 | |

| Total | 1000 | 1000 | 1000 | 1000 | |

| PVC(%) | 40 | 40 | 40 | 40 | |

| Stormer, equilibrated(KU) | 99.8 | 101.2 | 99.5 | 98.7 | |

| Heat-Aged Stability, 60 Deg C, 1 week(KU) | 98.2 | 100.3 | 97.1 | 97.2 | |

| High shear viscosity(P) | 0.31 | 0.36 | 0.20 | 0.58 | |

| Gloss 60° | 24.2 | 28.7 | 28.5 | 22.8 | |

| Syneresis, 1 week, 60°C(%) | Syn. | Slightly Syn. | No Syn. | No Syn. |

Sheen Paints thickened with Acrylic emulsion binder

| Components | SH610 | SH611 | SH612 | |

| Grind | Deionized Water | 170.9 | 170.9 | 170.9 |

| Propylene glycol | 20 | 20 | 20 | |

| HIDIS 40 | 2 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | 0.5 | |

| AMP95 | 0.5 | 0.5 | 0.5 | |

| Mergal K14 | 1 | 1 | 1 | |

| TRONOX CR828 | 140 | 140 | 140 | |

| OMYA CARB10 | 30 | 30 | 30 | |

| Let down | Deionized water | 92.5 | 93.5 | 95.5 |

| HISOL AC111 | 380 | 380 | 380 | |

| HIQUE 332 | 120 | 120 | 120 | |

| Triton CF10 | 1.5 | 1.5 | 1.5 | |

| Propylene glycol | 6 | 6 | 6 | |

| Texanol | 6 | 6 | 6 | |

| Nopco 8034L | 0.6 | 0.6 | 0.6 | |

| Ammonia | 2 | 2 | 2 | |

| HIRESOL 85 | 6 | 5 | 3 | |

| HIRESOL 2000 | 20 | - | - | |

| HIRESOL 1800 | - | 20 | - | |

| HIRESOL 500 | - | - | 20 | |

| Total | 1000 | 1000 | 1000 | |

| PVC(%) | 40.14 | 40.14 | 40.14 | |

| Stormer, equilibrated(KU) | 93.5 | 95.3 | 92.8 | |

| Stormer, heat-aged Stability, 60 °C, Weeks passed, KU | 87.8 | 88.6 | 85.3 | |

| ICI, poise(P) | 0.68 | 0.68 | 0.64 | |

| Gloss 20° | 4.2 | 3.4 | 3.7 | |

| Gloss 60° | 30.9 | 27.8 | 29.9 | |

| Syneresis, 1 week, 60°C(%) | No Syn. | No Syn. | No Syn. |

Sheen paints based on Acrylic emulsion binder

| Components | SH610 | SH611 | SH612 | |

| Grind | Deionized Water | 170.9 | 170.9 | 170.9 |

| Propylene glycol | 20 | 20 | 20 | |

| HIDIS 40 | 2 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | 0.5 | |

| AMP95 | 0.5 | 0.5 | 0.5 | |

| Mergal K14 | 1 | 1 | 1 | |

| TRONOX CR828 | 140 | 140 | 140 | |

| OMYA CARB10 | 30 | 30 | 30 | |

| Let down | Deionized water | 92.5 | 93.5 | 94.5 |

| HISOL AC111 | 380 | 380 | 380 | |

| HIQUE 332 | 120 | 120 | 120 | |

| Triton CF10 | 1.5 | 1.5 | 1.5 | |

| Propylene glycol | 6 | 6 | 6 | |

| Texanol | 6 | 6 | 6 | |

| Nopco 8034L | 0.6 | 0.6 | 0.6 | |

| Ammonia | 2 | 2 | 2 | |

| HIRESOL 85 | 6 | 5 | 4 | |

| HIRESOL 2000 | 20 | - | - | |

| HIRESOL 1800 | - | 20 | - | |

| HIRESOL 500 | - | - | 20 | |

| Total | 1000 | 1000 | 1000 | |

| PVC(%) | 40.14 | 40.14 | 40.14 | |

| Stormer, equilibrated(KU) | 96.5 | 94.6 | 93.8 | |

| Stormer, heat-aged Stability, 60 °C, Weeks passed, KU | 99.6 | 94.9 | 94.5 | |

| ICI, poise(P) | 0.78 | 0.74 | 0.72 | |

| Gloss 20° | 4.1 | 3.4 | 3.7 | |

| Gloss 60° | 30.2 | 26.7 | 29.9 | |

| Syneresis, 1 week, 60°C(%) | No Syn. | No Syn. | No Syn. |

Sheen paints based on Acrylic emulsion binder

| Components | HG710 | HG711 | |

| Grind | Deionized Water | 133.1 | 133.1 |

| Propylene glycol | 20 | 20 | |

| HIDIS 40 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | |

| Nopco 8034L | 0.4 | 0.4 | |

| AMP95 | 0.5 | 0.5 | |

| Mergal K14 | 1 | 1 | |

| TRONOX CR828 | 185 | 185 | |

| OMYA CARB10 | 30 | 30 | |

| Let down | Deionized water | 70 | 70.8 |

| HISOL AC115 | 492 | 493 | |

| HIQUE 387 | 40 | 40 | |

| Triton CF10 | 1.5 | 1.5 | |

| Propylene glycol | 20 | 20 | |

| Texanol | 6 | 6 | |

| Nopco 8034L | 0.4 | 0.4 | |

| Ammonia | 3.6 | 3.6 | |

| HIRESOL 308 | 4 | 3.2 | |

| HIRESOL 2000 | 20 | - | |

| HIRESOL 1800 | - | 20 | |

| Total | 1000 | 1000 | |

| PVC(%) | 20.1 | 20.1 | |

| Stormer, equilibrated(KU) | 93.5 | 93.8 | |

| Stormer, heat-aged Stability, 60 °C, Weeks passed, KU | 96.4 | 93.4 | |

| ICI, poise(P) | 0.98 | 0.89 | |

| Gloss 20° | 27.5 | 29.1 | |

| Gloss 60° | 69.2 | 69.2 | |

| Syneresis, 1 week, 60°C(%) | No Syn. | No Syn. |

Semi-Gloss paints based on Acrylic emulsion binder

| Components | HS1020 | HS102 | |

| Grind | Deionized Water | 199.4 | 199.4 |

| Propylene glycol | 20 | 20 | |

| HIDIS 40 | 2 | 2 | |

| Triton CF10 | 0.5 | 0.5 | |

| Nopco 8034L | 0.5 | 0.5 | |

| AMP95 | 0.5 | 0.5 | |

| Mergal K14 | 1 | 1 | |

| TRONOX CR828 | 180 | 180 | |

| Let down | Deionized water | 58 | 59 |

| HISOL AC115 | 426 | 426 | |

| HIQUE 387 | 70 | 70 | |

| Triton CF10 | 1.5 | 1.5 | |

| Propylene glycol | 6 | 6 | |

| Texanol | 6 | 6 | |

| Nopco 8034L | 0.6 | 0.6 | |

| Ammonia | 2 | 2 | |

| HIRESOL 308 | 6 | 5 | |

| HIRESOL 2000 | 20 | - | |

| HIRESOL 1800 | - | 20 | |

| Total | 1000 | 1000 | |

| PVC(%) | 24 | 24 | |

| Stormer, equilibrated(KU) | 94.2 | 94.3 | |

| Stormer, heat-aged Stability, 60 °C, Weeks passed, KU | 99.5 | 95.7 | |

| ICI, poise(P) | 0.74 | 0.73 | |

| Gloss 20° | 20.5 | 19.2 | |

| Gloss 60° | 63.1 | 61.1 | |

| Syneresis, 1 week, 60°C(%) | No Syn. | No Syn. |

Semi-Gloss paints based on Acrylic emulsion binder

| Components | FM204 | FM184 | |

| Grind | Deionized Water | 150 | 150 |

| HIDIS 40 | 20 | 20 | |

| Triton CF10 | 2 | 2 | |

| Nopco NXY | 0.5 | 0.5 | |

| Natrosol 250HBR 3% | 0.5 | 0.5 | |

| TRONOX CR828 | 0.5 | 0.5 | |

| Talc#400 | 1 | 1 | |

| OMYA CARB10 | 180 | 180 | |

| Let down | Ethylene Glycol | 10 | 10 |

| Nopco NXY | 3 | 3 | |

| HIDIS AC53 | 190 | 190 | |

| Deionized water | 86 | 76 | |

| HIRESOL 308 | 5 | 5 | |

| HIRESOL 2000 | 30 | - | |

| HIRESOL 1800 | - | 20 | |

| Ammonia | 4 | 4 | |

| Mergal K14 | 3 | 3 | |

| Texanol | 5 | 5 | |

| HIQUE 387 | 60 | 60 | |

| Total | 1000 | 1000 | |

| PVC(%) | 64 | 64 | |

| Stormer, equilibrated(KU) | 96.4 | 94.8 | |

| Heat-Aged Stability, 60 °C, 1 Week, KU | 96.2 | 95.3 | |

| High shear viscosity(P) | 1.4 | 1.12 | |

| Syneresis, 1 week, 60 °C(%) | No Syn. | No Syn. |

Suppliers of Raw Materials

| Name | FM204 | FM184 |

| HIDIS 40 | Dispersant | HLC |

| Triton CF10 | Wetting Agent | Dow Chemicals |

| Nopco NXY | Defoamer | San Nopco Korea Ltd. |

| Mergal K14 | Biocide | Troy chemical |

| TRONOX CR828 | TiO2 | TRONOX INCORPORATION |

| Talc#400 | Extender | DongYang Materials Industrial Co. Ltd. |

| OMYA CARB10 | Extender | Omya Korea |

| HISOL AC115 | Acrylic emulsion | HLC |

| HIDIS AC53 | Styrene-Acrylic emulsion | HLC |

| Texanol | Coalescing agent | Eastman |

| Natrosol 250HBR | Thickener | Aqualon |

| HIQUE 387 | Opaque Polymer | HLC |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM MOON SOO

- Address

- #321-21,Gongdan-Dong ,, Gumi-Si, Gyeongsangbuk-do,

- Product Category

- Other Paint & Coatings

- Company introduction

-

Hankuck Latices Co., Ltd. (HLC) has been researching and developing, producing, and selling additives for the Korean domestic and international water based paint and paper coating industry for over twenty years. Following stringent operating principles, HLC develops new production processes and products using environmentally friendly methods, constantly increases reliability to domestic and global customers through ever improving services, promotes the welfare of employees and their families, and encourages social responsibility through profit generation.

- Main Markets

-

Egypt

Egypt

Greece

Greece

India

India

Malaysia

Malaysia

Viet Nam

Viet Nam

- Main Product

Related Products

DETDA(Diethyl toluene diamine) Polyurea curing agent

Medical Grade PVC Compound

_2.jpg)

Ceramic Queen(Superhydrophobic Nano-Ceramic Coating for car)

CHEMICAL

Apolipoprotein E (ApoE) Genotyping Kit