Concrete Pile Pole Plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Taeshin Corporation

- Verified Certificate

-

17

| Product name | Concrete Pile Pole Plant | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Concrete Filling Equipment

The concretefilling machine is designed to fill concrete mixture into a lower mould. The machine is equipped with built-in weigh-hopper, screw feeder and digital controller. It fills weighed concrete in to a lower mould pre-cisely according to the size of pole and pile.

Underneath the concrete filling machine, a filling cart is installed on the rall to recelve concrete mixture. All the process is precisely controlled by PLC

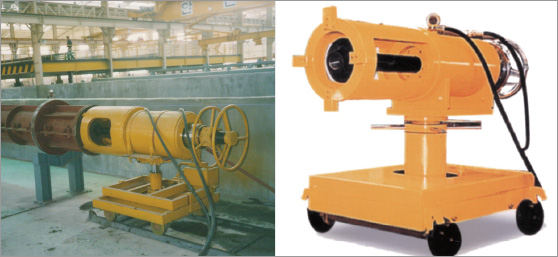

Prestressing Equipment

Welded cage of P.C. wire is pre-stressed by pretension jack.

With exact and equal tension on all P.C wires, pre-stressed concrete poles and piles shall have extra durability and tensile strength.

It consists of a hydraulic cylinder and digital pressure Indicator

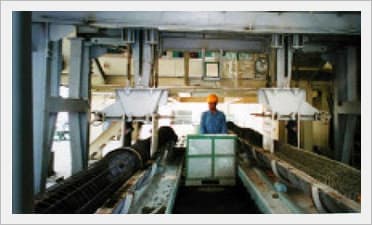

Centrifugal Spinning Machine

This equipment spins the mould, which contains contains concrete mixture and pre-stressed P.C wire cage. Two rows of rollers are driven by V-belt from motor. The spinning speed is automatically controlled by 4-steps speed control.

Pole & Pile Casting Mould

Moulds are made to be balanced statically and dynamically for vibration-free running.

Pile & Pole Vacuum Lifter

Vacuum lifter, affixed to the hoist crane, holds the finished product with lifting capacity up to 8.5ton

Shock-Absorber & Star Feeder

Star feeder is for smooth loading of a complete mould assembly on the chain conveyor after curing process and demoulding. Shock-absorber helps to load mould on the chain conveyor by absorbing shocks with air-operated process.

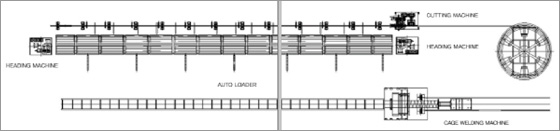

Automatic P.C Wire Cutting Machine

Automatic P.C Wire cutting machine cuts wire precisely by set point control. The machine consists of Cutter-drive by flywheel, feeding rollers, multiple length preset stoppers, discharge slot, automatic control panel, DC brake and P.C wire coil stand. The work-able diameter of P.C wire is 7~13mm with accuracy +-1~2mm at the cutting speed of 37~42m/min.

P.C Wire Heading Machine

P.C Wire Button-head forming machine is to form button-head at both ends of P.C wire by instant electrical heating method.

The workable diameter of P.C wire for forming button-head is 7~13mm at the speed of 12~15s/head.

P.C Wire Processing Layout

Automatic P.C Pile Cage Welding Machine

The automatic P.C pile cage welding machine makes complete cylindrical cage of P.C wires through automatic spiral welding.

|

Description

|

PIWT-600

|

PIWT-800

|

PIWT-1200

|

|

Cage Diameter

|

Ø300~600mm

|

Ø450~800mm

|

Ø700~1200mm

|

|

Cage Length

|

7~18m

|

7~18m

|

7~18m

|

|

Diameter & No Longitudinal Wires

|

Ø7.2~13mm & 6~36ULBON wires

|

||

|

Diameter & Pitch of Spiral wire

|

Ø3.2~6mm at 25~125mm & Variable pitch

|

||

|

Transformer

|

84~125KVA with SCR Control-water cooling

|

||

|

Control

|

Automatic control with PLC and/or Inverter

|

||

Automatic P.C Pole Cage Welding Machine

The automatic P.C pole cage welding machine makes complete conical pole cage of P.C wires through automatic spiral welding

|

Description

|

Specification In General

|

|

Diameter & No. of Longitudinal Wires

|

6.1, 7.4, 11, 13mm & 6~28pcs

|

|

Cage Diameter

|

140~240mm

|

|

Conicaity

|

1/60, 1/66, 1/75 or customer's adjustment

|

|

Cage Length

|

6~24m(L)

|

|

Dimeter & Pitch of Spiral Wire

|

2.3~6mm at 25~100mm & Variable pitch

|

|

Transformer

|

84~125KVA with SCR Control water colling

|

|

Control

|

Automatic control with L,C PLC and / or Inverster

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- AHN, SANG-CHEOL

- Address

- 15-2 Koju-ri, Paltan-myon, Hwasung-city, Kyongki-do, 445-910, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Taeshin Corporation is Korea's leading manufacturer and exporter of complete equipment of Spun Prestressed Concrete Pole and Pile, Concrete Batching Plant and Asphalt Mixing Plant.

Each of SPC POLE and PILE production equipment are not built to be something to every customers. But everything are built to someone as tailor-made equipment for customers of SPC POLE and PILE production.

- Main Markets

-

Malaysia

Malaysia

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea