Chemicla Blowing Agent

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

Kumyang Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Chemicla Blowing Agent | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Descriptions

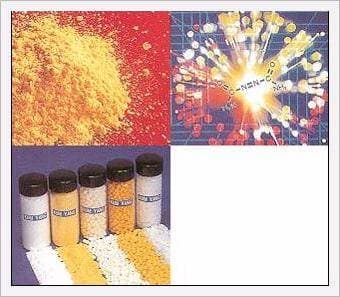

Chemical blowing agent is a chemical additive that is able to evolve gas through thermal decomposition and produce foam structures in a polymeric matrix. It is largely classified into two: one is organic chemical blowing agent and the other is inorganic chemical blowing agent. Commercial chemical blowing agents produced by Kum Yang are outlined as follows.

- Azodicarbonamide (CellcomAC Series)

- p,p'Oxybis(benzene sulfonylhydrazide) (CellcomOBSH Series)

- pToluenesulfonyl hydrazide (CellcomH Series)

- pToluenesulfonyl acetone hydrazone (CellcomKE)

- N, N'Dinitrosopentamethylenetetramine (CellcomA80s)

- pToluenesulfonyl semicarbazide (CellcomTSS)

- 5Phenyltetrazole (Cellcom5PT)

- Sodium Bicarbonate (Kycerol Series)

The special features of main chemical blowing agent besides AC are as follows.

| Product Name | Appearance | Decomposition Temp (‘C) | Gas volume (ml/g) | Feature | Mainusage |

| CELLCOM- OBSH Series | White Powder | 155 - 165 | 120 -130 | Use for low Temp.process without promoters, and non-staining, non-discoloring. Release non-toxic N₂gas. Closed cell | PVC, EVA, EPDM & CR |

| CELLCOM- H Series | White Powder | 148 -154 (103 -107) | 120 -130 | Use for low Temp.process without promoters, and non-staining, non-discoloring. Release non-toxic N₂gas. Closed cell | RUBBER (NR, SBR, IIR) |

| CELLCOM- KE | White Powder | 172~179 | 90~110 | Fine regular sponge cell structure & excellent dispersion in rubber | RUBBER (NR, SBR, Hi-styrene & Neoprene) , |

| CELLCOM- A80 | Light Yellow Powder | 175 -185 (201~203) (in cap.) | 210 - 255 | Highest decomposition calories | EVA & RUBBER |

| CELLCOM- ACP Series | Light Yellow Powder | 125 ~ 135 | 160~180 | Mixed blowing agent with AC & DTP. Low temp. process and whiteness | EVA , PE & RUBBER |

| CELLCOM- TSS | White Powder | 229 - 235 | 150 -160 | High temp. processing and whiteness | ABS, PP, HIPS, HDPE, PVC |

| CELLCOM- 5PT | White Powder | 234 - 245 | 180 up. | Highest temp.processing and non-ammonia | PC, NYLON, PET, ABS, Fluoro Plastics |

| KYCEROL Series | White Powder | 150 ~ 190 | 115 ~ 125 | Non-toxic, non-odor, endothrmic blowing function.Release CO₂ | PE, PS, PVC, ABS, HIPS |

Blowing technology can be widely useful for plastics & rubber application where requires weight reduction, cushion, sound & water absorption, elastic property, thermal & electric insulation, touch & decoration improvement, dimensional stability, impact strength reinforcement and so on. You must select the most suitable blowing agent according to their species, specialty, application, processing methods and conditions in cases of plastics and rubbers. Please refer our general selection guide of Cellcom Blowing Agent below attached.

Best Selection for Suitable Blowing Agent Please check the properties of ideal chemical blowing agent to make proper sponge.

- The blowing gas must be evolved within a defined temperature and time.

- Regular particle size and excellent dispersion in the plastic.

- The blowing agent should be controlled the decomposition temperature and generated low heat.

- The gas foamed should not have corrosive action.

- The decomposition residue should be non-toxic and non-pollution

- The decomposition residue should not effect to the foam in its chemical and physical properties

- Non-effective in Polymeric crosslinking and vulcanization.

- The blowing agent should have a high gas yield and be economic.

- The blowing agent should have good transportation and storage stability. And select the general blowing agent according to the resin and processing methods.

Please refer the selection guide as follows.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kwang-ji, Ryu

- Address

- 951-1, Gamjeon-dong, Sasang-gu, Busan, Korea

- Product Category

- Dyestuffs

- No. of Total Employees

- 51-100

- Company introduction

-

Thank you for visiting our homepage of Kumyang Co.Ltd.

Our company Kum Yang was founded in 1955 and had been the leading group in the fine chemical industry and also had contributed a lot in the local economic development. Since we got over lots of difficulties and trials, we are making a 2nd founding movement to reborn.

In the background of 50 years, we have a big know-how of making fine chemical products. To be the world leading company in blowing agent market, we are constantly changing our business to high value added structure to achieve the international competitiveness and to be an expert company in the fine chemistry field. And to achieve the goal, Kum Yang is concentrating to upbring the high value added fine chemical products and high functioned additives as a future strategic project.

Our main product is foaming agent, and the base of its stability and competitiveness, we are currently producing medical supplies additives and cosmetic additives in the Quzhou Plant which is located in the Zhejiang Province in China. We are planning to magnify these kinds of high value added fine chemical products and also develop a new high skilled additive business to secure high growth operating organization.

- Main Markets

-

China

China

Hong Kong(China)

Hong Kong(China)

Taiwan

Taiwan

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

_2.jpg)

Ceramic Queen(Superhydrophobic Nano-Ceramic Coating for car)

TiO2 Photocatalyst

Medical Grade PVC Compound

Bisphenol-A(BPA)

CHEMICAL