plastic moulding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- vogoge

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Molds

vogoge technology

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | plastic moulding | Certification | - |

|---|---|---|---|

| Category | Molds | Ingredients | - |

| Keyword | plastic injection mould , plastic moulding , plastic injection molding maker | Unit Size | - |

| Brand name | vogoge | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 121220702 |

Product Information

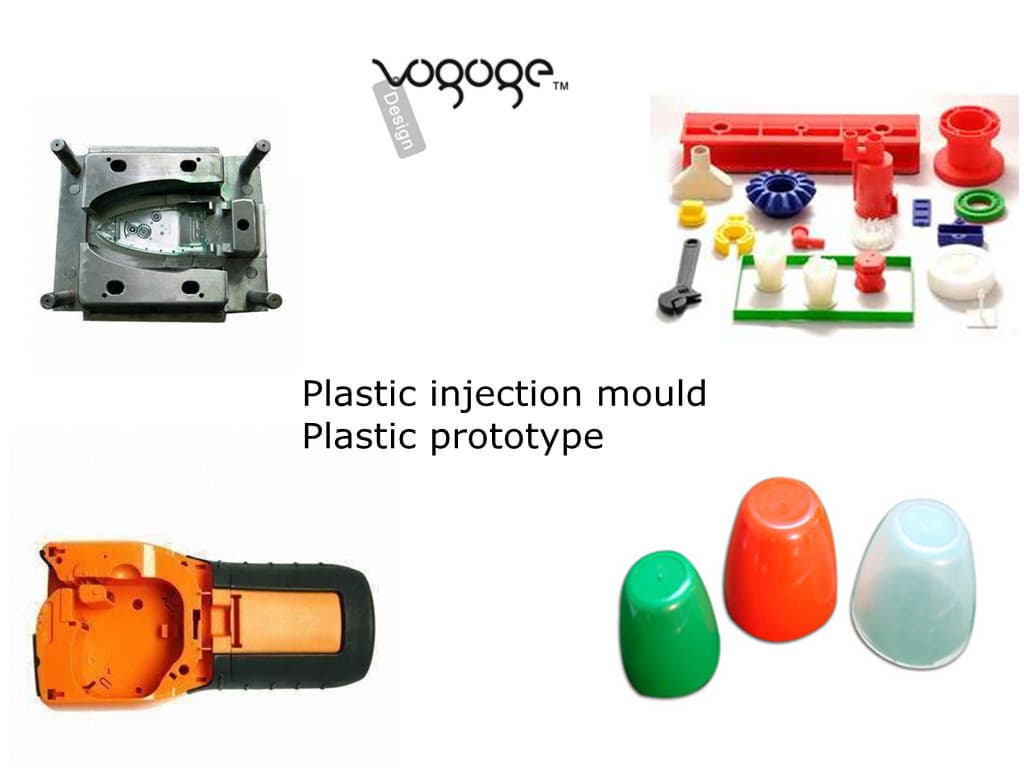

plastic moulding

1.2738 mould material

2.Die life:600000 shot

3.Provide OEM,ODM service

Business Type:

Rapid prototype

CNC machining

Plastic injection mould

Die casting

Full Service Capabilities for Plastic Injection Molding

Long and short plastic injection molding production runs

Low cost molding service

Mold design & injection fabrications, assembly, packaging and delivery

Insert molding, dual-color molding service

24-hour plastic molding manufacturing shifts

On-site injection plastic mold repair & maintenance

Injection Molding Presses ranging from 50 - 450 tons

Secondary process including painting, printing and assembly

General Grades:

ABS,

Engineering Grades:

PA12(Grilamid TR55),

PA66(Dupont Zytel Rynite132F,KOPA KN333G30),

TPE(GLS CL2242,),TPR,TPU, PPS(Fortron 0220A9 130A64),

LCP(Ticona Vectra A700), PEEK(VICTREX 450G), PSU(UDEL P-1700),

POM(Ticona Celcon M90), PVDF(Kynar 720, 740, Solef 6010), PET(Eastman Durastar MN631),

PBT(Dupont Crastin 6130, LANXESS POCAN B 3235 901510).

We are sparing no efforts on each process to ensure the quality.

1. Mould Design Control

2. Mould Steel Hardness Inspection

3. Mould Electrodes Inspection

4. Mould Core and Cavity Steel Dimension Inspection

5. Mould Pre-Assembly Inspection

6. Mould Trial Report and Samples Inspection

7. Pre-Shipment Final Inspection

8. Export Product Package Inspection

QC procedure:

1.part mold draft analysis

2.mold design control

3.steel hardness inspection

4.demension inspection of electrode / cavity and core

5.mold trial report and inspection report

6.shipment inspection

Project management

1.drawing in format of Auto CAD or igs ,x-t,stp etc ,or sample from customer

2.offer and solution from YiXun

3.order confirm and deposit paid

4.part mold draft analysis

5.mold disign

6.GA drawing confirmed by customer

7.design ok

8.mold production

9.mold T1 trial

10.trial sample confirmed by customer

11 .mold shipping or mass injection

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Rudy liu

- Address

- Unit 201,2th Floor,Building B,Wanli Ye Technopark,8th Chong Qing Road,Fu Yong,Bao’an District,Shenzhen,China

- Product Category

- Machinery Parts Processing Services

- Main Product