GRP Pipe

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Chemical Machinery Equipment

Dongil CNE Co.,Ltd.

- Country / Year Established

-

South Korea

/

1980

South Korea

/

1980

- Business type

- Manufacturer

- Verified Certificate

-

16

| Product name | GRP Pipe | Certification | - |

|---|---|---|---|

| Category | Chemical Machinery Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

GRP pipe can be fabricated in various ways. The following is GGT standard for the fabrication of GRP pipes.

Filament wound method is generally used to produce GRP pipe.

Merit of GRP Pipe

The FRP is a widely proved composite material with high strength and corrosion resistance.

- Corrosion Resistance

Both the inner and outer surfaces of the FRP pipe are corrosion resistant, eliminating the need for a lining process. - Strength to Weight Ratio

The specific strength of the FRP pipe exceeds that of steel and stainless steel - Light Weight

Fluidity in the FRP pipe is excellent because of small resistance and coefficient of friction (C=150), reducing the pumping cost. The inner surface is rarely worn by any possible sands or gravel. - Size Variety

The FRP pipe is available from 15 mm to 2.5 m in diameter. The standard lengths supplied are 6, 9, and 12m. - Low Thermal Conductivity

The FRP pipe has low thermal conductivity, saving the cost of heat insulation. - Low Thermal Expansion

The FRP pipe has low thermal expansion, lowering deformation and the number of expansion joints required. - FDA Compliance

The FRP is made of the certificated materials from FDA, so that the pipe can be used in applications for drinking water.

Applications

The FRP pipe requires no regular maintenance, allowwing any above ground, under ground, and subaqueous applications. Do you have to check and repair your steel pipes Just replace them with the FRP pipes, which is serviceable semi-permanently

- Sea Water intake & Outfall Piping

- Circulation piping for coling water

- industrial alpplicated food Processing

- Chemical transfer rocessing

- Potable & Sanitary Piping

- Chlorination piping

- Sewage piping

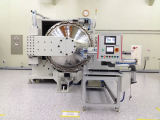

Fabrication of GRP Pipe

GRP pipe can be fabricated in various ways. The following is GGT standard for the fabrication of GRP pipes. Filament wound method is generally used to produce GRP pipe.

A. Filament Wound

Filament winding is processed as following: First, roving is immersed into resin. And wind it continuously on rotational structure called "mandrel" (normally spiral way) Filament winding is used to fabricate pipes similar to tubes. And, fiberglass roving strand is impregnated into liquid thermosetting resin and wound on the rotational axis which has special pattern(Generally, angle is 54.5° )

The most outstanding characteristics of filament winding products is that the mechanical stiffness is very high and the capability of absorbing impact energy is great.Resins are 30~40% because stiffness is regarded as very important factor for pressure vessel, pressure pipe and tank, etc. This is depended on resin volume, winding angle. Thus, fabrication method should be selected appropriately considering it's use.

Surface veil or chopped strand mat are used inside of filament-wound pipe to enhance resistant power against corrosion.B. Hand Lay-up

Hand Lay-up is a way of lamination by laying resin and glass fiber alternatively on mold until lamination thickness reaches to some point.

This method is used to fabricate fittings and it has advan -tage of getting various form and shape by laminating using glass fiber, chopped strand mat and roving cloth in orderly manner, And, even complicated shape also can be obtained.

It is very important to eliminate bubbles during lamination and in order to complete lamination structure, segregation is performed manually with rollers and resin is used to be 60~70% of total volume.Physical properties can vary depending on the mixing ratio between roving cloth and chopped strand mat.

Thickness formation of GRP Pipe

GRP pipe is used for a system requiring highly non-corrosive and very strong stiffness. And, due to it's structure, it has very long life time, almost forever. Basic material(resin) and supporting material (glass fiber) are used reasonably and this structure makes the lifetime very long with high stiffness. Especially, GRP pipe can be fabricated appropriately according to liquid and system by selecting proper resin and fabrication method for best service with the system.

- Liner Layer

C-glass fiber is used so it has excel -lent non-corrosion property against

chemical liquids. - Structural Layer

E-glass fiber is used and it is supp -orting layer of GRP pipe with

mechanical and physical stiffness. - External Layer

It protects GRP pipe from aging and

deformation originated from environm -ental factor such as ultraviolet rays.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Segeuk Noh

- Address

- 898-46, Hogye-dong, Dongan-gu, Anyang-si, Gyeonggi-do, Korea

- Product Category

- Other Rubber Products

- Year Established

- 1980

- No. of Total Employees

- 101-500

- Company introduction

-

GD Ecotech was established in 1980 as a professional manufacturer of protection equipment for preventing environment contamination and non-corrosive equipment for industrial use.

GD Ecotech has produced various treatment equipment and system for toxic gases such as VOC, Sox and dust. It has designed, fabricated and installed such environment protection facilities and scrubber(horizontal type scrubber, vertical type scrubber), FRP duct, FRP fan & blower, FRP lining, pipe & fittings, FRP cover. Also, it has produced enhanced plastic baths of non-corrosive products to be used as various tanks and plating baths.

We localized the exhaust system technique for semiconductor manufacturer since 1990, which is for a facility against air pollutant. The gas scrubber, one-step upgraded highly efficient environment facility to treat wasted gases from semiconductor processes, is able to eliminate acid, alkali, bad odor and dust up to 99% level.

Also its size is diminished than existing scrubber and more effective by 30% in maintaining cost so that not only even in semiconductor industry but also other industries such as pharmacy, steel, chemical and fiber industries have used our system broadly

In addition to the above, we took over the technique for the elimination of NOX & DIOXIN from Samsung Engineering Company and have commercialized this to use in eliminating VOC(Volatile Organic Compound) of industrial field, bad odor and other various harmful toxic gases.

We have developed equipment and systems to be used in such fields and also expanded to the area of treatment of polluted waters. We all the employees are aiming our all efforts to make our company a complex for environmental techniques and facilities.

- Main Product