Alumina Grinding Mill Media

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery Parts

Inbest Ceramic Inc. Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | Alumina Grinding Mill Media | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

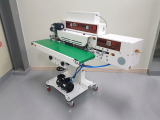

Alumina Grinding Mill & Media

High density Alumina lining mill & media can be used widely in the mineral processing, ceramic, white cement, abrasive material and paint industry. For general purpose grinding, we supplies two materials : A90, which offers superior density and abrasion resistance, and A995 has recommended for the highest purity media in critical environments where corrosives may attack the media, or media induced product contamination is a concern.

The ball shape is preferred for converting large-size feed material into finely ground products. Natural shape is best when there's little requirement for primary size reduction and it's an extremely efficient shape for dispersing solid into a vehicle. The rod media are particularly effective in vibration mills and should be used when a uniformly fine product of limited size range is required.

Size requirements differ with the material being ground or dispersed the feed size and finish size. Generally, the largest media selected should be at least 5 time larger than the largest feed particle.

Maintain the media charge at48%~55% of total mill volume in batch-type mills and 38%~42% in continuous mills.

We recommends 55% to 65% of critical mill speed for optimum grinding performance.![]()

Dry grinding requires faster mill speeds than wet grinding![]()

Ball Mill Spec. & Grinding Ball Charge

|

Type

|

Drum

size (mm) |

Lining

Thick (mm) |

Drum size

After Lining (mm) |

Useful

vol(L) |

Revolution

(RPM) |

Power

(kW) |

About

Total Weight (kg) |

Ball

Charge (kg) |

|||

|

Drum

|

Side

|

Wet

|

Dry

|

Wet

|

Dry

|

||||||

|

BM-50

|

480x505

|

25

|

25

|

420x450

|

55

|

37

|

49

|

0.75

|

1.5

|

400

|

60

|

|

BM-100

|

606x606

|

25

|

25

|

530x530

|

110

|

35

|

47

|

0.75

|

1.5

|

450

|

120

|

|

BM-150

|

606x757

|

38

|

38

|

530x682

|

150

|

35

|

47

|

0.75

|

1.5

|

550

|

160

|

|

BM-200

|

748x748

|

38

|

38

|

668x668

|

230

|

32

|

42

|

0.75

|

1.5

|

620

|

250

|

|

BM-300

|

810x810

|

38

|

38

|

730x730

|

310

|

30

|

40

|

1.5

|

2.2

|

720

|

340

|

|

BM-400

|

909x909

|

38

|

38

|

800x800

|

400

|

28

|

37

|

1.5

|

2.2

|

850

|

430

|

|

BM-500

|

950x1000

|

50

|

50

|

845x922

|

510

|

26

|

35

|

2.2

|

3.7

|

1,250

|

550

|

|

BM-600

|

965x1168

|

50

|

50

|

860x1058

|

610

|

26

|

35

|

2.2

|

3.7

|

1,350

|

660

|

|

BM-1000

|

1212x1212

|

50

|

50

|

1094x1094

|

1,030

|

24

|

32

|

3.7

|

5.5

|

2,100

|

1,110

|

|

BM-1300

|

1313x1313

|

50

|

50

|

1193x1193

|

1,330

|

24

|

32

|

3.7

|

5.5

|

2,800

|

1,400

|

|

BM-2000

|

1515x1515

|

50

|

50

|

1395x1395

|

2,130

|

22

|

25

|

7.5

|

11.0

|

3,800

|

2,300

|

|

BM-3000

|

1818x1818

|

50

|

50

|

1698x1698

|

3,840

|

20

|

23

|

11.0

|

19.0

|

5,000

|

4,200

|

|

BM-5000

|

2120x2120

|

50

|

50

|

1950x1950

|

5,820

|

18

|

21

|

19.0

|

22.0

|

8,000

|

6,300

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Seungyong KIm

- Address

- (zip code 210-340 )#308, Fine Ceramics Center, 898-1, Daejeon-Dong, Gangneung-si, Gangwon-do, Korea

- Product Category

- Vases

- No. of Total Employees

- 1-50

- Company introduction

-

We are special company of Ceramic Lining, Ceramic Precision Machine Component, Metallizing Products

Since founded in Jan, 2009, Inbest Ceramic provide wear resistant Ceramic Lining, fine ceramics parts for Power Plant such as Chute, Cyclone, Roller , Orifice, etc. For past a few years, Inbest Ceramic has been accumulating the technologies that make big and huge ceramics in Alumina, Zirconia Based Ceramic Product. We promise to provide you with only the best products and high quality service as well as offer our support

- Main Product

Related Products

Vagcom 17.1.3 ATMEGA162 VCDS 17.1.3 China crack VAG 17.13 Fo

180 degree rotation brushless servo XQ-S5650D

FR Coating

EMI Shielding Metal Spring Gasket

vacuum band-cylinder