Silver Spherical Powder

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

Phoenix P.D.E. Co., Ltd.

- Country / Year Established

-

South Korea

/

1983

South Korea

/

1983

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | Silver Spherical Powder | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

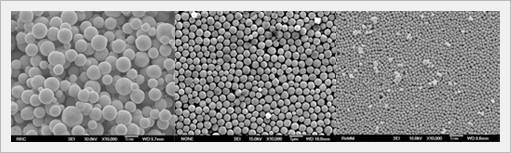

Silver Spherical Powder

Ag spherical powder is widely used for core component of Ag paste which bus electrode and Address electrode of Top & Bottom glass Bus electrode on top glass is used for metallic electrode which supply same voltage in all transparent electrode of discharge cell. Bus electrode on top glass is possible to form minute pattern. Also lower resistance value, lower reflexibility and matching with dielectric layer are required. Address electrode on bottom glass is used for metallic electrode which supplies addressing-pulse. Address electrode on bottom glass has thin plastic film and in case of re-plasticity, it dose not occur the snapping of a wire. Easy patterning characteristic such as excellent adhesion, minuteness and lower resistance value is required.

As Phoenix PDE systematically established metal powder producing process and characteristic evaluation system, we can implement the optimized powder manufacturing process with various size, and productivity is excellent due to the design of consecutive process. Moreover, it is simple to apply to other metal powder producing technology due to its excellent powder shape and size distribution.

Characteristic & Core Technology

Ag spherical powder of Phoenix PDE has the excellent electrical characteristic & uniform size distribution, on account of this, it has excellent matching property with nearby material and easy for forming minute pattern. Phoenix PDE has secured supreme managing technique in powder shape and size distribution based on high efficiency producing process of PDP electrode material & Reproducibility and Phoenix PDE supplies Ag spherical powder which satisfies customer's need with this core technology.

Special Feature of AG spherical powder

- Secure the control technology in particle size such as 200nm, 500nm, 1.0~4.0μm and so on

- High electrical conductivity and stable printing ability

- Secure excellent matching ability with dielectric layer

Special Feature of manufacturing process

- Secure consecutive manufacturing process.

- Secure Reproducibility of powder manufacturing & reliability.

- Establish characteristic evaluation system of metal powder

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Chol Inho

- Address

- 130, Gongdan-dong, Gumi-si, Gyeongsangbuk-do, 730-030 KOREA

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1983

- No. of Total Employees

- 101-500

- Company introduction

-

Business conditions were difficult in 2005, yet we managed to maximize our sales and profitability. We managed to make Korea the world foremost PDP powder producer by expanding our production capacity and achieving global competitiveness. This segment will serve as a key platform for our future growth.

Our business climate is expected to be more difficult in 2006 than it was last year, and the hurdles we face continue to get higher. The Won currency will continue to appreciate against the Dollar, while prices for raw and secondary materials are expected to rise. Environmental regulations continue to be tightened and competition in the marketplace is intensifying steadily. However, all of the employees at Phoenix PDE are dedicated to constant innovation and improvement and are unafraid of new challenges. Thus, we aim to carry out the following three objectives in the coming year:

First, we will maintain our leadership position in the electronics materials segment. The display business should be brink in the coming year, with major sporting events such as the World Cup and Asian Games being held. Competition between the PDP and LCD formats for TV is severe, exerting downward price pressure on both. Phoenix PDE has built close relations with PDP makers.

Second, we will focus our competencies on advancing the nano-materials business. We are currently developing nano-level metal materials, and expect some of our silver and solder products to be commercially available in the first half of 2006. Importantly, we aim to offer quality and precision that is superior to that of our competitors, and cultivate this segment into a future growth engine.

Third, we will promote a corporate culture in which efficiency and passion thrive. In recent years we have been pursuing the Six Sigma program, TPS (Toyota Production System), and various innovation acceleration campaigns. May you and your families have a happy and prosperous 2006.

- Main Markets

-

Brazil

Brazil

China

China

India

India

Malaysia

Malaysia

Thailand

Thailand

- Main Product