Polishing Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

A-Tech Ltd.

- Verified Certificate

-

17

| Product name | Polishing Machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

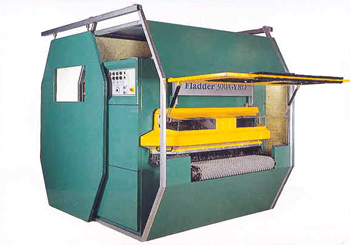

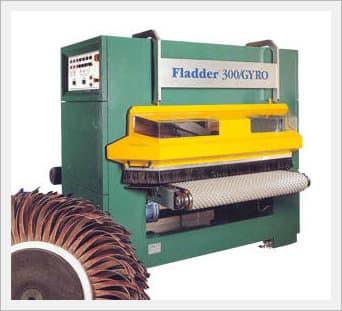

| Fladder/ GYRO

-. Operation

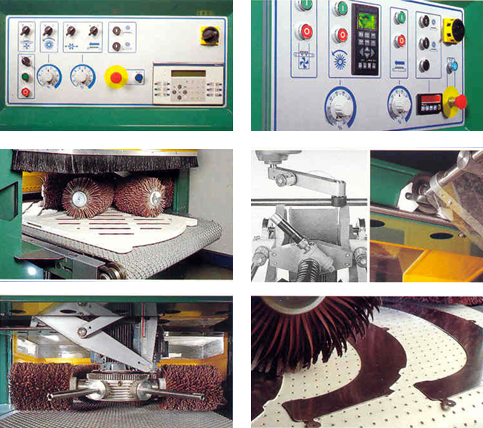

The machine is highly user-friendly. All functions are accessed from a central control panel with symbols indicating the functions, making it easy and clear for the operator to work the machine. As several functions are synchronised, this also minimises the risk of making faulty settings.

The operator can monitor the porcess through a nomber of windows in the machine's cabinet and shields, and if required he can adjust settings during the sanding process. It goes without saying that the machine is equipped with interior light.

Depending on the thickness of the part, the abrasive position may be set by means of a number of push-buttons which move the tool futher away from of closer to the part. A display on the operating panel provides a digital read-out of the tool's position in relation to a preset base position.

Then, all that remains is to start the vacuum system, set the values for the sanding spindles and possibly the speed of the conveyor belt. All other functions are automatically synchronised with these functions.

-. Vacuum and shields

All parts are held in place on the machine's conveyor belt by a powerful vacuum system. The vacuum is created by one or two centrifugal pumps which evacuate the air through the many holes in the conveyor belt.

This means that even small parts are taken safely through the process, no matter where they are placed on the belt. The shields also ensure safety and will stop the process entirely if opened during operation.

The shields may be fully opened to facilitate access to the inside of the machine for maintenance, e.g.replacement of abrasives, service and inspections. Finally, the shields also serve to suppress the noise.

-. Energy

The machine pressrves energy. Most motors are controlled by frequency converters, which mean that the motors are always supplied just the right amount of energy. At the same time, the frequency converters are programmed with the maximum motor load values motors' operation if these values are exceeded.

The use of frequency converters also allows variable power transmission directly to a motor and thus to the associated function. Just to name one example, the power is transferred directly from the main motor to the spindles. If this function were to be controlled by means of a gear, this would result in a loss of energy.

-. Central gear head

The central head carrying the tools is an extremely strong and compact unit. The housing is made from a single piece of aluminium with cooling fins on the outside, and the inside is specifically designed to house the special gears in Chromium MolybdenumVandium Steel.

The strong design allows trasmission of high torque values, making it possible to use of several types of FLADDER abrasive tool. Furthermore, the construction may be modified to use other types of tool, for instance disc polishers.

The central head with a main motor and rotation motor is mounted in an ingenious, unique scissor-type suspension system. By opening and closing the scissor arms, the head can be lifted and lowered, respectively, to the right position. The scissor arms are resting on four wheels of specially hardened and milled steel, allowing them to move.

This makes it possible to create the linear, oscilating movement across the conveyor belt.

Each of the wheels if equipped with mechanical scrapers which automatically scrape off any dust from the wheels and rails. The wheels, rails (GYRO-models) and oscillating guides (GYRO+AUT-models) are equipped with convenient lubricating cartridges which automatically supply the appropriate amount of lubricants.

-. Conveyor Belt

Like all the other components in the cachine, the conveyor belt is a component of the highest quality. The belt is an endless belt consisting of several layers of synthetic fibre material covered by a layer of natural rubber for improved friction properties.

This provides great accuracy, which ensures accurate tracking of the belt throughout its life cycle. The drive shaft's convex shape reduces the belt's create an efficient vacuum which will easily hold even amall parts in place.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim, Soung-eun

- Address

- 178-2, Suyu-dong, Gangbuk-gu, Seoul

- Product Category

- Other Machinery & Industry Equipment

- Company introduction

-

A-Tech was established on first of June in 1999. We mainly deals in optical instruments like Microscope, endoscope, LCD Projector etc and measuring instruments like Data logger, thermometer, metal processing instruments etc and lab instruments like image processor etc.

We do business with laboratory, university, quality control department so our items are suitable for field to need precision.We have been providing domestic buyer with grinding machine of Fladder Co. in Denmark

That product is 3D processing machinery so you could apply our goods to precision manufacturing like aircraft, metal processing, and plastic, wood processing.

Thank you very much.

- Main Product

South Korea

South Korea