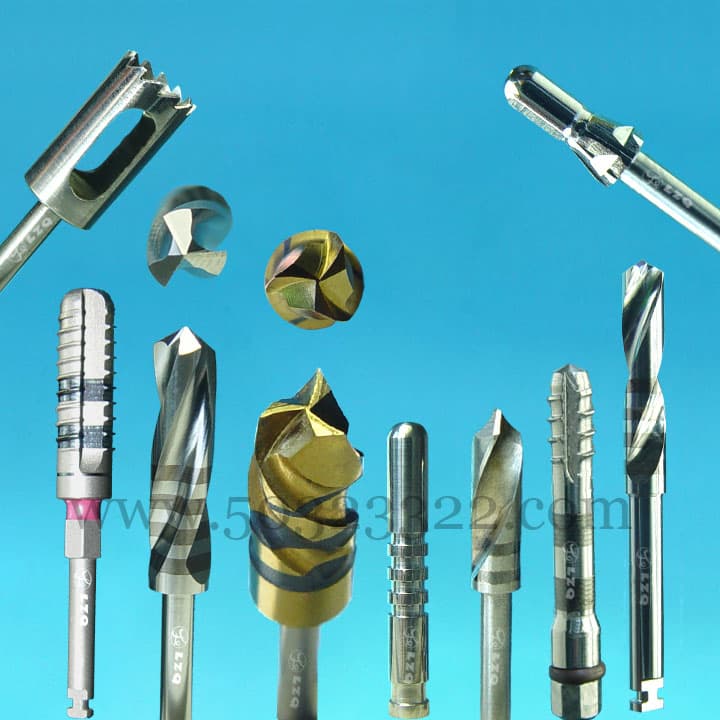

bone drill,hollow bone drill,medical bone drill

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- LZQ

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- drill bits, bone drill, bone drill pin, medical bone drill

- Category

- Machinery & Parts , Medical Devices

Shanghai LZQ Precision Tool Technology Co.Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

15

| Product name | bone drill,hollow bone drill,medical bone drill | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Medical Devices |

Ingredients | - |

| Keyword | drill bits , bone drill , bone drill pin , medical bone drill | Unit Size | - |

| Brand name | LZQ | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Trephine Bur,hollow bone drill

(Stainless /wear resistance/high temperature-resistance/high precision)

Products:Stainless bit,OT cutting Tool,Stainless Steel Tool,Stainless Steel Tools,Stainless steel needle drilling,Stainless steel screwdriver,Bone Drill,Screwdriver, Needle Drill, Medical bit, Profile drilling-mill forming stainless high speed steel, Carbide drilling-mill.

| M10 | NX22 | NS520 | T05A T110A | TN60 | LN10 | CH350 | CT525 | KT125 | TTI-15 | IC30N | CM |

| NX2525 | WG300 | T12Z | TN6020 | CA200 | CC670 | KT175 | TTI-25 | C15M | |||

| AP25N | AT530 | WX120 | PV60 | CS100 | CT5015 | KY4300 | M,U | ||||

| GT530 | NX260C | PV7020 | CX50 | GC1525 | Y4000 | ||||||

| Y2000Z | KY2000 |

(N10 HTI10 TH10 EH10 KG10 K10K313 )

(M20 GM127 CNX725 RW2110)

(K20 G-10 CYC600 YG6 )

(S10 EH510 H10F K313 )

SKH4C: (a kind of high speed steel, which does not rust at all.)(Hardening treatment: HRC60°±2°)

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 3-6 times than normal stainless products. Moreover, AIS1440C and SUS440C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.

VRA201:

Imported ultra micro-grain diamond tungsten steel, with excellent impact-resistance and general wear-resistance. Generally applied in worse or general equipment to machine materials of lower hardness (HRC≤25°), discontinuous cutting and worse part fixture. Conforming to ISO K25, can replace machining of materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6 times lifetime, it has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime and durability.

ASP60C :

imported ultra high wear-resistant high-grade high cobalt powder steel, quenched:HRC70°±2°, with excellent wear resistance and impact resistance. Comparing with HSSE\HSS-AL and HSSCo, it has 4~8 times lifetime, and can guarantee uniformity and conformity rate of machined products. It is often applied in general equipment for machining various materials including Ni\Cr\Mo\Si\Ti) that are hard to machine like high alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool before heat treatment. It has excellent high temperature machining and comprehensive performance, and allows higher cutting speed. The higher the hardness of machined materials, the more remarkable the effect. Because its roughness is not so good, it is not suitable for discontinuous cutting or for using under processing system of insufficient rigidity, otherwise, cutter will be hit or chipping will happen..

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 3-6 times than normal stainless products. Moreover, AIS1440C and SUS440C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.

MR11: (For high wear-resistant application):

Ultra micro-grain quality carbide has property of excellent wear resistance and ideal impact resistance. It is applied in mid, high speed intermediate cutting machining of various materials that HRC 28°~48°. It is an ideal machining tooling for finish machining and material tempering, and it is extensively applied. Comparing with general tungsten steel, it has 2~3 times more lifetime. Generally it is applied in good and stable work conditions, good part fixture and continuous mid, high speed light-duty cutting. After being TiALN coated, it has better performance, can machine various materials of HRC 60° Conforming to ISO K10~K30/P10~P30. It is often applied in CNC equipment to machine various hard-machining materials (containing Ni, Cr, Mo, Si, Ti etc.) like high temperature alloys, heat-resistant alloys, Ni-V-Ti alloys, cast iron, stainless steel etc., ultra excellent machining tools before heat-treatment and after tempering. High temperature machining and integrated property is good, allowing highest cutting speed (generally linear speed is above 120M) and with low feed requirement. The higher hardness of the machining material, the better performance. Due to its bad toughness, it is not applicable for discontinuous cutting or for conditions in which process system's rigidity is not sufficient and there is chattering, jumping, otherwise, the blade will be hit or chipping will happen.

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Shanghai LZQ Precision Tool Technology Co.Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

15

- President

- Mr huang

- Address

- 3 Floor # 1269, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai. China

- Product Category

- Machinery & Parts,Saw

- No. of Total Employees

- 101-500

- Company introduction

-

Shanghai LZQ Precision Tool Technology Co., Ltd. is a high-tech joint venture, located in Plant #1269, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai. In the light of China's Rejuvenation, Great Harmony, Propagating health, Joyancy & Sunny……LZQ has been accumulating over 20 years rich experience on R&D and producing CNC precision cutting tool, profile fixture, brazing fixture, wear-resistant parts, high-precision parts, and carbide grinding tool for medium-end and high-end exporting market. By dint of the cutting-edge & comprehensive production system, LZQ is possessed of rich producing & machining capability with different precision technology, we have introduced world first-class CNC Processing Center, Super High-Speed Compound Grinding-Turning Center, and Ultra-micro Premium Carbide Tool Hardware, high-precision (3DX Technology) profile carbide & ultra-precision grinding; our products are able to processing various material whatever is micro-thin, ultra-long, ultra-thin, ultra-wear-resistant, impact-resistant, top complex, and combined profile, will all provided with perfect cutting quality and tolerance fine to ±0.0005mm (±0.5μm), and what a high-efficiency & low-cost application we deliver you! We keep around RMB 8~10 Million turnover stock articles such as raw material, semi-products, finished products in ordinary year, we are capable to produce according to drawing or sample provided by customer and make delivery within one week, so as to present you a favorable cost-performance ratio……Our company usually produces every kind of implant dental and bone tool for big medical company from Germany, Sweden, France, Japan, Korea and etc. There are 28 specifications in common dental implant tool box including drill, tap, and driver and so on. Every customer has difference in the type of drill bits, such as length, helical angle and others.

Every customer has different demands. Some needs only drills, some needs to make segmentation mark, which helps doctor to know the depth of drilling. Some also needs to make color ring. However, I give our list in quotation for you. And you can check our photo and then you can know what the meaning of segment mark, color ring and coated is. If you have any questions, don’t hesitate to contact me, we will serve you with our warm heart.

And there are also some customers who want coated, like when we manufacture for Germany and France companies, we need to make coated, the normal coated is with yellow color, I attach our photos for your reference, please check. And when we make for Korea, they prefer to black color coated. I want to know what kind of color you need. Yellow or Black or material own color? More customers want material own color.

Those drills are our superior products, if you have any express account number, we can send our stock for your test, and you can test many aspects, like sharp, wear-resistance, rust-prevention, and surface beauty and so on. Those can totally substitute products imported from some countries. If you need some kind of implant dental tool, please send us detailed specification or samples in order to make quotation and produce, thank you very much!

- Main Product

Related Products

Modbus Device Recorder

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING

Flange

INCYTO Needle

_2.jpg)

Micro Probe System (MPS-PTH)