| Product name |

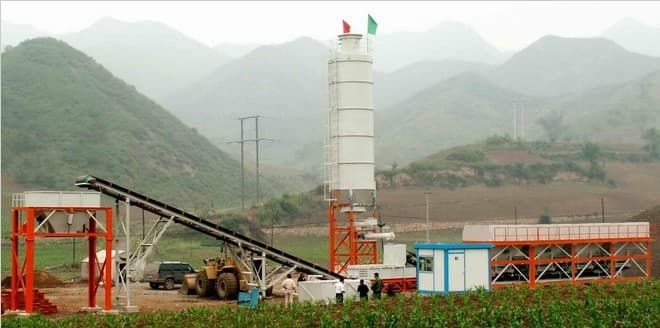

STABILIZED SOIL MIXING PLANT |

Certification |

-

|

| Category |

Home & Kitchen

|

Ingredients |

- |

| Keyword |

asphalt mixing plant

,

concrete mixing plant

,

bitumen mixing plant

,

stabilized soil mixing plant

|

Unit Size |

-

|

| Brand name |

yueshou |

Unit Weigh |

-

|

| origin |

|

Stock |

- |

| Supply type |

- |

HS code |

- |

Product Information

Detailed Product Description high quality, good services, low price capacity:300t/h-700t/h Collocation of MWB300 Stabilized Soil Mixing Plant I Whole Equipment 1.The rated production capacity : grit stabilized soil 300t/h Spodosol stabilized soil 260t/h 2. Total power: 83.58KW 3. Total weight: about 35T 4. The max diameter of the aggregate: 60mm 5. The accuracy of the aggregate : ≤±2% 6. The accuracy of the powder system: ≤±1% 7. The assembly form: the removable modular type 8. The area : 40×10=400m2 9. Movement control system form: manual or automatic operation II Aggregate Batching and Supply System i. Hopper (4 bins) 1. Volume : 9.2 m3 (single bins) 2. The overall dimension: 13368×2350×3614mm(length×width×height) 3. The charging height : 3.2m 4. The combination form: three united silos and one single silo form four storehouses 5.Collocation requirement: matched with two vibrating sieves and one insulated sieves two sieve jolter , two storehouse jolter all the jolters are flat , and its power:1.1KW ii. Measuring device 1. Measuring device: four weighing computerized belt conveyor scale 2. The control manner: controlled by computer, regulate the rotate speed of belt scale by transducer 3. System accuracy : ≤±2% 4. Measuring range: 250t/h(max) 5. Belt: width 800mm length, 5880mm 6. Power: 3KW(single belt scale ) iii. The mixture conveyor 1. Effective length: 16.4m 2. The width of the belt: 800mm 3. Work-capacity: 400t/h 4. Motor power: 7.5kw 5. Belt speed: 1.6m/s III Powder Supply and Measure System i. The powder silo 1. Quantity : 1 unit 2. The volume: 50t(cement density ) 3. Diameter : Φ2400mm 4. Dust collecting device: pulsator ZF-18-50 power 180w 5. The breaking arch device : the pneumatic breaking device is installed at the discharge gate ii. The measuring device 1. Baffle plate gate valve: 600×450 2. The overflowing auger: 4Kw the measuring auger: 2.2 kw 3. Control manner: controlled by the computer. regulate the auger speed by the transducer 4. The system accuracy : ±1% 5. The measuring range : 0~30t 6. The conveying manner: the powder is conveyed into the mixer through rigid gate valve and overflowing auger IV. Water Supply System 1. The water tank volume: 8m3 2. The water pump model: diving pump QY40-12-2.2 3. The pump flow rate 40 m3/h 4. The pump lift 12m 5. The motor power: 2.2Kw 6. Measure form: manual 7. The system accuracy : ≤-1%~+2%. V The Mixing Plant 1. Type: twin-horizontal shafts forced continuous type 2. Production capacity: 0-300t/h 3. Overall dimension: 3434×1310×1675( length ×width×height ) 4. Blade quantity: 40 5. Blade material: Rare earth alloy 6. The allowed max diameter: 60mm 7. Motor power: 37kw 8. The speed reducer model: ZQ75-15.75-4 9. The driving style: single motor driving 10. Rotation speed: 62rpm VI Finished Product Conveyor 1. The effective length 18.5m 2. The belt width: 800mm 3. The belt speed 1.6m/s 4. The working capacity: 400t/h 5. The hoisting height: 6m 6. The installation inclined angle: 18°C 7. The motor power: 7.5kw VII Storage Device 1. The bin volume: 7m3 2. The discharging height: 3.4m 3. The passage width: 3.5m 4. Driving mode: Pneumatic, Air compressor’s power: 5.5kw 5. Control manner: electromagnetic valve control 6. The jolt power : 1.1 KW VIII Pneumatic System 1. The pneumatic component: high quality pneumatic component 2.The usage : It is used for the breaking arch for the powder bin It is used for the opening of the finished products gate IX Control Room Monitoring of operating room: heat-preserving compound board with air- conditioner X Control System Control system: computer control Batching control system is consisted of upper inspecting system, PLC control system, transducer and locale-sensor unit. Introduction of control system: 1. Have manual and automatic function, which can be switched. Using computer control system must adopt Chinese interface. 2. Control room, covering 6.5 square meters, has solid structure and seal well as well as functions as sound-insulating, heat-insulating, moisture-proof, dust-proof. Installing with air –containers of corresponding capacity broadened the visual field so we can see the operating condition of the whole system. According to the procedure and demand of man-machine engineering science, the meter, alarming equipment, urgent control system, keyboard and controlling-screen are rationally collocated, so easy to operate. 3. Circuit system is provided with functions as protection against over-loading, pressure-lacking, over-heating 4. Computer control system can reveal the parameter of setting and actual statistics of individual metric scale. When lack stuff, it will send out signals and the pulsator will open automatically. 5. Production management system can store more than 30,000 pieces of data, and it is convenient to change those data and save producing statistics

B2B Trade

| Price (FOB) |

Negotiable

|

transportation |

-

|

| MOQ |

Negotiable |

Leadtime |

Negotiable

|

| Payment Options |

Negotiable |

Shipping time |

Negotiable

|

China

/

China

/

China

/

China

/