Cold-Rolled Steel Pipes

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Stainless Steel

HYUNDAI HYSCO Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Cold-Rolled Steel Pipes | Certification | - |

|---|---|---|---|

| Category | Stainless Steel | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

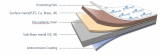

Pickling & Oiling

Enhancement of quality and productivity through automation of pickling line process and rolling process. Ultra fine thickness control and superb shape with application of new AGC and WR Shift. Production of Pickling Oil Steel with superior quality of shape in result of enhancement of pickling method by Turbulent Pickling System. Capability of high-strength steel and super-wide product with the proper thickness by customer's request by using the new and superior rolling mill.

CR

CR production with splendid shape and uniform quality of material. Provision of super-wide width stable and consecutive quality by application of Thermal Crown Control System in order to meet the diverse demand from costomers. Provision of superb-surface CR through CVC SPM. Usage : Car, Home Appliance and Construction material.

Applications

Pickling & Oiling

|

Classification |

Quality Characteristics

|

Usage

|

Specification |

||

|

Automobile

|

Home Appliance

|

Others

|

|||

|

Hot Rolled Mild Steel

|

Commercial Quality

|

|

|

|

SPHC, SPHD, SHPE

|

|

Hot Rolled Steel form Automobile Structural Uses

|

High Strength & Fatigue Resistance

|

|

SPFH490, SAPH370, SAPH400, SAPH440 |

||

|

Hot Rolled Steel form Automobile High Strength Uses

|

High Strength & Good Ductility

|

|

PFH490, SPFH540, SPFH590, SPFH540Y, SPFH590

|

||

CR

|

Classification |

Quality Characteristics

|

Usage

|

Specification

|

||||

|

Automobile

|

Home Appliance

|

Others

|

Applications

|

||||

|

Class1

|

CQ (Commercial Quality)

|

Used for exposed or unexposed parts where bending, shallow drawing, forming, and welding may be involved. |

|

|

|

Refrigerator doors, Drums, Furniture

|

SPCC

|

|

Class2

|

DQ (Drawing Quality)

|

Used form fabrication identified parts where drawability is needed.

|

|

|

Automovile oil pans

|

SPCD

|

|

|

Class3

|

DDQ (Deep Drawing Quality)

|

Used for deep drawing parts where more drawability is needed than DQ.

|

|

|

Roofs, fenders and hoods of automobiles

|

SPCE(N)

|

|

|

EDDQ (Extra Deep Drawing Quality)

|

Used for parts of automobiles where more drawability is needed than with DDQ.

|

|

|

Quarters and spring house of automobiles

|

CRE

|

||

|

SQ

(Structural Quality) |

High Strength & Structural Quality

|

|

|

CRS30, CRS32, CRS34, CRS37, CRS41, CRS46, CRS50, CRS58

|

|||

|

HSS

|

Commercial Quality

|

Adding hardening elements, Nb, Cr, and V to low carbon steel gives this type of steel its high strength and yield strength. It has excellent crack resistance and is used for structural purposes where strength is needed. |

|

|

Seats, rail levers and parking brake of automobiles

|

SPFC440, SPFC490, SPFC590

|

|

|

Drawing Quality

|

This is high strength steel made by adding such soild solution hardening elements as P and is used in parts like automobile panels to enhance strength.

|

|

Center floors and brackets of automobiles

|

SPFC390, SPFC440

|

|||

|

Deep Drawing Quality

|

This steel is made by adding elements to ultra low carbon steel. Its elongation is excellent and is used in deep drawing parts for outer panels of automobiles.

|

|

|

Outer panels such as fenders and hoods of automobiles

|

SPFC340, SPFC370

|

||

|

Dual Phase

|

By baking after press forming, the yield strength of the steel is heightened and its dent-resistant property is improved. The formability is the same as CRHS 35.

|

|

|

Outer panels such as fenders and hoods of automobiles

|

SPFC340H

|

||

|

Bake Hardening

|

In constant temperature, it forms a ferrite matrix grain and has a lower yield strength radio than that of high strength steel. It is used as a strength enhancing material.

|

|

Doors and bumpers of automobiles

|

SPFC490Y, SPFC590Y, SPFC780Y, SPFC980Y

|

|||

Hyundai HYSCO Specifications

|

Classification

|

Symbol

|

TS

(kgf/mm2) |

Minimum Elongation(%)

|

|||||

|

0.25≤t<0.45

|

0.45≤t<0.60

|

0.60≤t<1.0

|

1.0≤t<1.6

|

1.6≤t<2.5

|

||||

|

Class1

|

Commercial Quality

|

CRC1

|

≥28

|

|||||

|

Light Drawing Quality

|

CRC2

|

≥33

|

≥35

|

≥38

|

≥39

|

≥40

|

||

|

Class2

|

Drawing Quality

|

CRD

|

≥34

|

≥36

|

≥40

|

≥41

|

≥42

|

|

|

Class3

|

Deep Drawing Quality

|

CRDD

|

≥36

|

≥38

|

≥40

|

≥41

|

≥42

|

|

|

Non-aging Deep Drawing Quality

|

CRDDN

|

≥36

|

≥38

|

≥40

|

≥41

|

≥42

|

||

|

Non-aging Extra Deep Drawing Quality

|

CRE

|

≥44

|

≥45

|

≥46

|

≥48

|

≥48

|

||

|

Structural Quality

|

CRS34

|

≥34

|

≥22

|

|||||

|

CRS37

|

≥37

|

≥20

|

||||||

|

High Tensile Strength Steel

|

Commercial Quality

|

CRHS45C

|

≥45

|

-

|

≥24

|

≥26

|

≥27

|

≥29

|

|

CRHS50C

|

≥50

|

-

|

≥23

|

≥25

|

≥25

|

≥25

|

||

|

CRHS60C

|

≥60

|

-

|

-

|

≥17

|

≥18

|

≥18

|

||

|

Drawing Quality

|

CRHS35R

|

≥35

|

-

|

≥32

|

≥34

|

≥35

|

≥36

|

|

|

CRHS40R

|

≥40

|

-

|

≥29

|

≥31

|

≥32

|

≥33

|

||

|

CRHS45R

|

≥45

|

-

|

≥28

|

≥30

|

≥31

|

≥32

|

||

|

Deep Drawing Quality

|

CRHS35E

|

≥35

|

-

|

≥33

|

≥35

|

≥36

|

≥37

|

|

|

CRHS40E

|

≥38

|

-

|

≥31

|

≥33

|

≥34

|

≥35

|

||

|

Bake Hardening

|

CRHS50DP

|

≥50

|

-

|

-

|

≥24

|

≥25

|

≥25

|

|

|

CRHS60DP

|

≥60

|

-

|

-

|

≥18

|

≥19

|

≥19

|

||

|

CRHS80DP

|

≥80

|

-

|

-

|

≥14

|

≥15

|

|||

BS EN Specifications

|

Classification

|

Steel Grade

|

YP (N/mm2)

|

TS (N/mm2)

|

Min. EL(%)

|

Min. r90

|

Min. n90

|

||

|

Steel name

|

Steel number

|

|||||||

|

EN10130

|

Cold Rolled Steel

|

DC01

|

1.0330

|

≤280

|

270/410

|

28

|

-

|

-

|

|

DC03

|

1.0347

|

≤240

|

270/370

|

34

|

1.3

|

-

|

||

|

DC04

|

1.0338

|

≤210

|

270/350

|

38

|

1.6

|

0.18

|

||

|

DC05

|

1.0312

|

≤180

|

270/330

|

40

|

1.9

|

0.2

|

||

|

r-bar aaaaaaa n-bar

|

||||||||

|

Alloy steel

|

DC05

|

1.0873

|

≤180

|

270/350

|

38

|

1.8

|

0.22

|

|

ASTM Specifications

|

Specification

|

Classification

|

Tests

|

||||||

|

ASTM A366-97

|

Commercial Quality

|

Sheet Coil

|

Closed in Bending

|

|||||

|

ASTM A620-97

|

Drawing Quality Specialled

|

Sheet Coil

|

-

|

|||||

|

ASTM A611-97

|

Structural Quality

|

Grade A

|

Yield Point(Ksi)

|

Tensile Strength(Ksi)

|

Min. Elongation(%)

|

Bending

|

||

|

Grade B

|

||||||||

|

Grade

C |

Type1

|

25 Min

|

42 Min

|

(Test Piece) 2 inch or 50mm |

26

|

1/2t

|

||

|

Type2

|

30 Min

|

45 Min

|

24

|

1t

|

||||

|

Grade

D |

Type1

|

33 Min

|

48 Min

|

22

|

1 1/2t

|

|||

|

Type2

|

40 Min

|

52 Min

|

20

|

2t

|

||||

|

Grade E

|

80 Min

|

82 Min

|

-

|

-

|

||||

DIN 1623 Part 1(1983) Cold-Rolled Steel Sheet and Strip for Cold Forming

|

Specification

|

Type of Deoxidation

|

Yield Point (N/mm2)

|

Tensile Strength (N/mm2)

|

Min. Elongation(%)

|

|

Lo=80mm

|

||||

|

St 12

|

-

|

280 Max

|

270 - 410

|

28

|

|

USt 13

|

U

|

250 Max

|

270 - 370

|

32

|

|

RRSt 13

|

RR

|

240 Max

|

270 - 370

|

34

|

|

St 14

|

RR

|

210 Max

|

270 - 350

|

38

|

DIN 1623 Part 2(1986) Cold-Rolled Steel Sheet and Strip for General Engineering Purpose

|

Specification

|

Type of Deoxidation

|

Yield Point (N/mm2)

|

Tensile Strength (N/mm2)

|

Min. Elongation(%)

|

|

Lo=80mm

|

||||

|

St 37-2G

|

-

|

215 Min

|

360 - 510

|

20

|

|

USt 37-2G

|

U

|

|||

|

St 37-3G

|

RR

|

|||

|

St 44-3G

|

RR

|

245 Min

|

430 - 580

|

18

|

|

St 52-3G

|

RR

|

325 Min

|

510 - 680

|

16

|

|

St 50-2G

|

R

|

295 Min

|

490 - 660

|

14

|

|

St 60-2G

|

R

|

335 Min

|

590 - 770

|

10

|

|

St 70-2G

|

R

|

365 Min

|

690 - 900

|

6

|

JIS G 3141(1996) Cold-Rolled Steel Sheet and Coil

|

Classification

|

Specification

|

Tensile Strength (N/mm2)

|

Minimum. Elongation(%)

|

||||||

|

0.25≤t<0.4

|

0.4≤t<0.6

|

0.6≤t<1.0

|

1.0≤t<1.6

|

1.6≤t<2.5

|

2.5≤t

|

||||

|

Commercial Quality

|

Class1

|

SPCC

|

(Min 270)

|

≥(32)

|

≥(34)

|

≥(36)

|

≥(37)

|

≥(38)

|

≥(39)

|

|

250 - 410*

370 - 490* 440 - 590* Min 550* |

Min 25*

Min 10* - - |

||||||||

|

Drawing Quality

|

Class2

|

SPCD

|

Min 270

|

≥34

|

≥36

|

≥38

|

≥39

|

≥40

|

≥41

|

|

Deep Drawing Quality

|

Class3

|

SPCE

|

Min 270

|

≥36

|

≥38

|

≥40

|

≥41

|

≥42

|

≥43

|

KS Specifications (KS D 3512)

|

Classification

|

Symbol

|

Tensile Strength (N/mm2)

|

Minimum Elongation(%)

|

||||||

|

0.25≤t<0.4

|

0.4≤t<0.6

|

0.6≤t<1.0

|

1.0≤t<1.6

|

1.6≤t<2.5

|

2.5≤t

|

||||

|

Class1

|

Commercial Quality

|

SPCC

|

≥270

|

≥(32)

|

≥(34)

|

≥(36)

|

≥(37)

|

≥(38)

|

≥(39)

|

|

Class2

|

Drawing Quality

|

SPCD

|

≥34

|

≥36

|

≥38

|

≥39

|

≥40

|

≥41

|

|

|

Class3

|

Deep Drawing Quality

|

SPCE

|

≥36

|

≥38

|

≥40

|

≥41

|

≥42

|

≥43

|

|

CR Equivalent Specifications

|

Classification

|

HYSCO

|

BS-EN (10130) |

ASTM |

DIN(1623) |

JIS(3141) |

KS(3512)

|

|

|

Class1

|

Commercial Quality

|

CRC1

|

(DC01)

|

(A366-97)

|

-

|

SPCC

|

SPCC

|

|

Light Drawing Quality

|

CRC2

|

SPCC

|

SPCC

|

||||

|

Class2

|

Drawing Quality

|

CRD

|

(DC03)

|

(A620-97)

|

St 12

|

SPCD

|

SPCD

|

|

Class3

|

Deep Drawing Quality

|

CRDD

|

(DC04)

|

(A620-97)

|

RRSt 13

|

SPCE

|

SPCE

|

|

Non-aging Deep Drawing Quality

|

CRDDN

|

(DC05)

|

St14

|

SPCEN

|

SPCEN

|

||

|

Non-aging Extra Deep Drawing Quality

|

CRE

|

(DC06)

|

|||||

|

High Tensile Strength Steel

|

Commercial Quality

|

CRHS45C

|

-

|

(A611-97)

|

-

|

SPFC440

|

SPFC45

|

|

CRHS50C

|

-

|

-

|

SPFC490

|

SPFC50

|

|||

|

CRHS60C

|

-

|

-

|

-

|

SPFC590

|

SPFC60

|

||

|

Drawing Quality

|

CRHS35R

|

-

|

-

|

-

|

-

|

-

|

|

|

CRHS40R

|

-

|

-

|

-

|

SPFC390

|

SPFC40

|

||

|

CRHS45R

|

-

|

-

|

-

|

SPFC440

|

SPFC45

|

||

|

Deep Drawing Quality

|

CRHS35E

|

-

|

-

|

-

|

SPFC340

|

SPFC35

|

|

|

CRHS40E

|

-

|

-

|

-

|

-

|

-

|

||

|

Bake Hardening |

CRHS50DP

|

-

|

-

|

-

|

SPFC490Y

|

SPFC50Y

|

|

|

CRHS60DP

|

-

|

-

|

-

|

SPFC590Y

|

SPFC60Y

|

||

|

CRHS80DP

|

-

|

-

|

-

|

SPFC780Y

|

SPFC80Y

|

||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM, WON KAB

- Address

- 265, YEOMP-DONG, BU-GU, ULSAN, KOREA

- Product Category

- Other Iron

- No. of Total Employees

- 1001-2000

- Company introduction

-

Dear Prospective Buyers: Thank you very much for your interest in HYSCO, an enterprise specializing in the manufacture of automotive steel sheet. Humanity has passed through the Stone Age and the Bronze Age, and we are now living in a civilization reliant on the forging and shaping of metal. Most of people tend to think that the steel industry is distantly removed from their everyday lives. But if you look around closely, you can easily see how deeply steel and iron are imbedded in almost every facet of our daily routine. Thus, archeologists have named this historical period the "Iron Age." HYSCO is a company that produces automotive steel sheet and various steel pipes. Of our numerous steel-based products and equipment, we largely focus corporate efforts on these two particular areas. HYSCO was first established as Kyung-il Industrial Co., Ltd. in 1975 and later renamed as Hyundai Pipe Co., Ltd in 1980. In 2001, on the cusp of the 21st century, we renamed the firm once again as HYSCO. In response to rapid changes in the steel industry and as befitting our position as a global leader, we have concentrated efforts on the uplift of profitability while still making a rich contribution to society. The cold rolling mill started commercial operation in 1999, and is a representative part of such change and progress. We would like you to watch our dynamic progress. With your constant interest, HYSCO promises to become the world? best manufacturer of automotive steel sheet and high value-added steel pipes. Thank you very much.

- Main Markets

-

Belgium

Belgium

China

China

India

India

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product